To effectively assess a solar solenoid valve’s functionality and performance, follow these essential steps: 1. Understand the valve’s specifications and features, 2. Prepare the necessary testing equipment, 3. Conduct a visual inspection, 4. Test the electrical components, 5. Evaluate valve operation under pressure, 6. Document findings for future reference. Focusing on the operational testing phase, it’s crucial to simulate the conditions under which the valve will be performing to gather accurate data, ensuring its reliability in a real-world application.

1. UNDERSTANDING SOLENOID VALVES

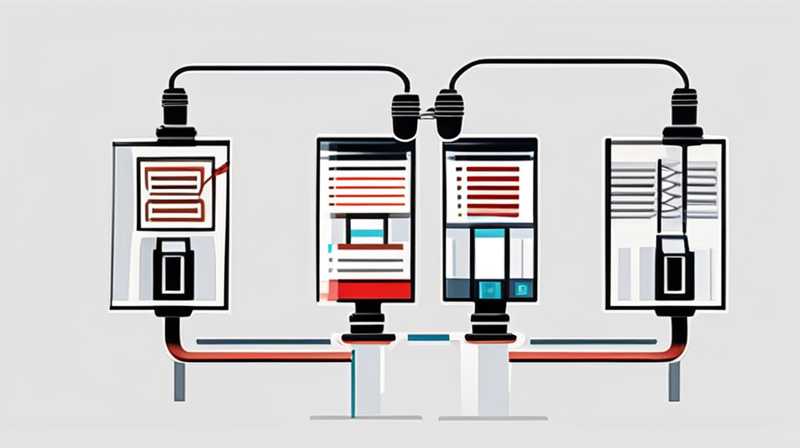

Solar solenoid valves are vital components in many applications, often used to control the flow of liquids or gases in systems powered by renewable energy. Grasping the fundamental operation and physical characteristics of these valves is crucial before conducting any tests. Essentially, a solenoid valve operates utilizing electromagnetic force to open or close the flow path, thus managing the fluid or gas passage effectively.

The construction of a solenoid valve typically consists of a coil, plunger, and housing. The coil generates a magnetic field when energized, moving the plunger within the valve body, either opening or closing the valve. Understanding the interplay of these elements is fundamental to performing an accurate assessment. Moreover, various designs, such as normally closed or normally open valves, and variations in sizes and materials, may influence testing strategies and results. Testing protocols should be tailored to match these diverse characteristics for comprehensive evaluations.

2. PREPARATION FOR TESTING

Before starting the testing procedures, ensuring that the necessary tools and equipment are at hand is imperative. Having a multimeter and appropriate pressure gauges is fundamental for electrical and mechanical assessments. Additionally, one must prepare a controlled testing environment that replicates real operating conditions to gather accurate, applicable results.

The preparation includes isolation and safety measures to prevent accidental shocks or damage during testing. Disconnecting power sources and securing the valve ensures a safe operational territory. Creating a checklist of inspection steps helps in systematically verifying all components. Ensuring equipment calibration is accurate before use can significantly influence testing outcomes. Each tool’s effectiveness can be compromised by improper calibration; hence, double-checking these settings is critical to achieving reliable and repeatable results.

3. VISUAL INSPECTION

Conducting a thorough visual assessment of the solar solenoid valve is an essential first step in the testing process. This stage involves examining all visible components for signs of wear, damage, or defect. Cracks, corrosion, and loose fittings can indicate underlying problems that may affect performance and longevity.

Inspecting seal integrity is crucial, as compromised seals can lead to leaks, which hinder system efficiency. Moreover, ensuring that there is no debris or obstruction in the valve or its surroundings is vital. Such obstructions can adversely impact the valve’s operation. Furthermore, checking the electrical connections for signs of burning or corrosion is essential, as poor connections can lead to improper solenoid functioning.

4. ELECTRICAL COMPONENT TESTING

A significant aspect of assessing a solar solenoid valve involves examining its electrical components. Using a multimeter enables one to measure voltage and resistance levels efficiently. First, ensure the valve is disconnected from any power source to prevent mishaps. Testing continuity through the solenoid coil can reveal potential failures in the winding or connections.

The ideal outcome is to measure the resistance according to the manufacturer’s specifications. If readings fall outside the expected range, this may indicate coil damage or circuitry issues. Additionally, verifying the current draw during operation can reveal more about the solenoid’s condition. Excessive current may suggest shorting or malfunction, warranting further investigation.

5. OPERATIONAL TESTING UNDER PRESSURE

Once electrical components are verified as functioning correctly, the next phase involves testing the valve under operational conditions. This stage should replicate the valve’s working environment. Proper pressurization of the fluid or gas flow through the valve offers insight into its true operating capabilities and potential weaknesses.

Monitoring flow rates when the valve is opened can divulge whether it operates within acceptable parameters. Observing response time when switching from open to closed states provides valuable feedback on performance and responsiveness. Additionally, checking for leaks during this phase is essential. Any indications of fluid escaping point towards a malfunctioning seal or valve structure that must be addressed promptly.

FAQs

WHAT IS THE PURPOSE OF A SOLENOID VALVE IN SOLAR SYSTEMS?

A solenoid valve in solar systems fundamentally controls the flow of fluids, such as water in solar thermal applications or coolant in photovoltaic systems. Its operation is typically managed by a microcontroller or timer that opens or closes the valve based on real-time conditions, ensuring optimal fluid circulation. This is particularly critical in systems utilizing solar energy, where efficiency directly impacts performance and energy savings. By regulating flow, solenoid valves help maintain desired temperatures in solar collectors, preventing overheating and promoting effective energy harvesting. In addition, they contribute to automated control, making solar systems easier to manage.

HOW CAN I DETERMINE IF MY SOLENOID VALVE IS FAULTY?

Determining the functionality of a solenoid valve involves several tests. Initial visual inspections can reveal obvious issues, such as physical damage, corrosion, or loose connections. Following this, using a multimeter to measure resistance in the solenoid coil helps identify electrical failures. If the readings do not align with the manufacturer specifications, this indicates potential solenoid failure. Furthermore, operational testing under simulated conditions can expose issues such as slow response times or leaks. If the valve is failing to open or close as it should, it may require replacement or repair.

HOW OFTEN SHOULD SOLENOID VALVES BE TESTED?

Regular testing of solenoid valves is essential for optimal performance, especially in solar applications where efficiency is critical. It is advisable to perform an initial comprehensive inspection upon installation, followed by annual evaluations. However, in systems subject to extreme conditions or frequent use, more frequent inspections may be warranted. Factors such as operational temperature, exposure to harsh environments, and operational cycles influence the frequency of testing. Maintaining a scheduled maintenance program ensures any issues are identified early. Regular assessments help to prevent unexpected failures and prolong the lifecycle of the solenoid valve.

Testing solar solenoid valves is an intricate process that demands attention to detail and methodical execution. Each phase of evaluation plays a role in ensuring that the valve operates as intended, directly affecting the overall efficiency of solar energy systems. Ensuring that all components, from electrical connections to physical structures, function optimally lays the groundwork for dependable performance. Comprehensive inspections and operational tests help identify inefficiencies or failures, thereby facilitating maintenance or replacements. Investing considerable time and resources into this testing phase is not merely advantageous; it is essential for optimal system functionality. Keeping abreast of maintenance schedules further augments system reliability, leading to an increased lifespan and improved energy yield. Thus, stakeholders in solar energy must prioritize effective testing of solenoid valves to glean maximum benefits from their systems, driving home the significance of proactive engagements in maintaining advanced technologies. Continuous education and training about the operational mechanisms of these valves will further empower individuals to conduct these tests with precision, ensuring that solar systems remain at the forefront of energy innovation, adhering to the principles of sustainability and efficiency.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-test-solar-solenoid-valve/