To set up a solar temperature control box, several essential steps must be undertaken to ensure efficient operation. 1. Assessing your requirements, 2. Selecting appropriate components, 3. Designing the system layout, 4. Implementing the control mechanisms. One crucial aspect is assessing your requirements, which involves analyzing the specific needs of your application such as desired temperature range, size of the area to be controlled, and the type of solar power system already in place. This foundational stage allows for a bespoke solution tailored to unique circumstances and enhances the overall efficacy of the solar temperature control box.

1. UNDERSTANDING THE SOLAR TEMPERATURE CONTROL SYSTEM

In the realm of solar energy, the significance of a temperature control box cannot be overstated. This device regulates the heat generated by solar panels, ensuring they operate within optimal temperature ranges. When solar panels overheat, efficiency decreases, leading to reduced overall energy production. Understanding how a solar temperature control box functions allows users to enhance the performance of their solar systems significantly.

A fundamental component of this mechanism is its ability to maintain optimal operating temperatures. Solar panels typically perform best within a certain thermal range, usually between 15°C and 35°C. When the temperature exceeds this range due to excessive sunlight or because of poor ventilation, the control box intervenes by either adjusting the angle of the panels, activating ventilation fans, or engaging cooling systems. Thus, it plays a crucial role in maintaining efficiency and prolonging the life of the solar infrastructure.

Moreover, understanding the working principles of a temperature control system is vital for potential users. It starts with sensing the temperature using thermistors or thermal sensors. These devices provide real-time feedback about the temperature conditions around the solar panels. The information gathered is relayed to a microcontroller—the brain of the control box—that executes predetermined algorithms based on the data collected. This technical interaction ensures that the system responds to temperature fluctuations in real-time, optimizing solar panel operation continuously.

2. ASSESSING NEEDS AND REQUIREMENTS

The first step in establishing a solar temperature control box involves an in-depth assessment of the specific needs and environment where the system will be implemented. Factors impacting this decision-making process include geographical location, climatic conditions, and type of solar technology in use. Each aspect plays a significant role in determining how the control system should be configured for maximum output.

Geographical location is paramount; regions subject to intense sunlight will need more robust control systems compared to locales with moderate sunlight. For instance, areas prone to consistent high temperatures may benefit from advanced cooling mechanisms that activate when predefined thresholds are crossed. These cooling methods might involve automatic adjustment of the solar panels’ angle or the operation of ventilation systems to enhance air circulation around the panels.

Additionally, understanding unforeseen challenges, like seasonal temperature variations or unexpected weather phenomena, is essential. The assessment phase should also encompass potential growth in energy requirements in the future. Preparing for such changes ensures the long-term viability of the system and avoids costly upgrades.

3. SELECTING COMPONENTS FOR THE CONTROL BOX

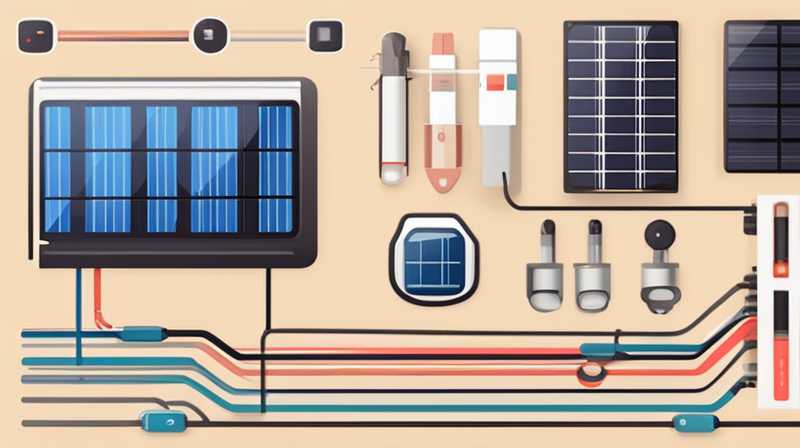

Once needs have been clearly defined, the next phase entails selecting the appropriate components that will make up the solar temperature control box. Choosing the right materials and sensors is critical for ensuring reliability and efficiency. Several essential components should be wisely considered during this stage, including sensors, controllers, actuators, and cooling equipment.

Thermal sensors are a vital part of the temperature control mechanism. Available in various types, including thermocouples, thermistors, and infrared sensors, these units measure temperature accurately and relay this information back to the control system. When choosing sensors, factors such as accuracy, response time, and environmental durability should be considered. More advanced sensors may offer additional features such as wireless connectivity, which can facilitate real-time monitoring and evaluation through mobile applications or cloud services.

The controller, usually a programmable microcontroller, takes charge of receiving data from the sensors and executing commands based on the pre-set algorithm. Selecting an appropriate controller ensures that the system can handle specific functions like data logging, managing multiple input/output ports, and integrating with existing solar system components. Furthermore, the choice of actuators, such as motors that can adjust the angle of solar panels or activate ventilation fans, is equally vital for implementing the required temperature adjustments effectively.

Cooling systems also merit attention during the selection phase. Various options exist, like passive cooling mechanisms through ventilation or active systems utilizing refrigeration. Choosing the right cooling mechanism is crucial as it directly influences the efficiency of the temperature control system. Ensuring that the selected components work synergistically leads to an effective and responsive temperature control box.

4. DESIGNING THE SYSTEM LAYOUT

The design of the solar temperature control box must take into account the spatial arrangement of components, as well as their integration with solar panels and other electrical systems. A well-thought-out layout can significantly impact the performance and efficiency of the temperature control system. Design considerations should include accessibility for maintenance, safety measures, and overall aesthetics.

Creating an efficient layout often involves a schematic representation that illustrates the positioning of control components, sensors, and power supply lines. It is immensely beneficial for technicians working on installation or troubleshooting, ensuring that all parts are correctly connected and functioning properly. Proper organization of cables and ventilation paths not only promotes airflow but also reduces the likelihood of accidents during maintenance operations.

Moreover, the design must account for environmental factors such as exposure to humidity, dust, and potential mechanical damages. Selecting suitable housing materials that offer both durability and appropriate thermal insulation is critical. Furthermore, accessibility to components for maintenance is crucial; therefore, positioning these elements in an easily reachable area ensures that system checks can be performed regularly, minimizing operational downtime.

5. IMPLEMENTING CONTROL MECHANISMS

With the design prepared, the next phase centers on implementing the control mechanisms that will govern the solar temperature control box’s operations. This stage involves coding the microcontroller to execute the temperature management algorithms, ensuring all components are properly connected, and performing tests to validate that the system processes accurately.

Programming the microcontroller is one of the most intricate aspects, as it requires knowledge of both the operating conditions and programming languages such as C or Python. The code should specify how the system should respond when temperature readings fall within certain thresholds, essentially defining the operational behavior of the control unit. Advanced programming may also involve integrating features for remote diagnostics and performance analytics, allowing end-users to stay informed and engaged with system health.

Testing the implemented control mechanisms is essential to ensure that all systems work harmoniously and that temperature regulation functions as intended. This may involve simulating various temperature conditions and observing the system’s response. Feedback from this testing phase can drive further refinements, including adjustments to programming or component calibration, leading to a more dependable operation.

6. MAINTAINING THE SYSTEM FOR LONGEVITY

After the solar temperature control box has been successfully established and calibrated, the next vital step is to ensure ongoing maintenance to achieve long-term reliability and performance. Regular maintenance minimizes the risk of breakdowns and keeps the system operating at its optimal efficiency level.

One key aspect of maintenance involves routine inspections of all system components, including sensors, controllers, and cooling mechanisms. Identifying issues early on, such as degraded sensors or misplaced wiring, significantly reduces the risk of system failure and optimizes performance. It is advisable to establish a maintenance schedule, detailing specific tasks based on the manufacturer’s recommendations and the system’s unique operational demands within a defined period.

In addition to hardware assessments, regular software checks are equally important. Updating the controller’s firmware or software can lead to performance enhancements and overall improvements in system efficiency. Furthermore, enhancing the system’s cybersecurity is essential to protect sensitive data and prevent unauthorized access, which can jeopardize system integrity.

Finally, keeping a log of maintenance activities and system performance data is invaluable for assessing long-term functionality and planning future upgrades. By adhering to a comprehensive maintenance strategy, users can maximize the lifespan of their solar temperature control box while reaping consistent benefits from their solar energy investments.

FREQUENTLY ASKED QUESTIONS

WHAT ARE THE BENEFITS OF A SOLAR TEMPERATURE CONTROL BOX?

A solar temperature control box offers numerous advantages that enhance solar energy systems. Primarily, it optimizes the operating temperature of solar panels, thereby increasing efficiency. When solar panels overheat, their energy production can significantly drop, leading to reduced overall performance. By maintaining optimal temperatures, a control box ensures that panels operate at their peak efficiency, especially during intense sunlight periods.

Another notable benefit is the prolongation of solar panel life. Consistently high temperatures can exacerbate wear and tear on the components, potentially leading to early failure. Therefore, a well-implemented temperature control box protects investment by minimizing such risks. Furthermore, many systems also integrate monitoring features that provide valuable data insights, allowing users to track performance metrics and make informed decisions about their solar energy setup.

Additionally, the installation of a solar temperature control system ultimately can result in long-term savings. Although initial setup costs can be significant, the increased efficiency and lifespan of solar panels translate into more energy harvested over time, thus maximizing return on investment. Therefore, the overall functionality, cost-effectiveness, and longevity of the solar system are substantially enhanced through the implementation of a temperature control box.

HOW OFTEN SHOULD THE THERMAL SENSORS BE CALIBRATED?

Thermal sensor calibration is an integral part of maintaining an efficient solar temperature control box. The frequency of calibration typically depends on the type of sensors used, the operating conditions, and manufacturer recommendations. However, a general guideline suggests calibrating sensors at least once a year to ensure accurate readings.

In environments with fluctuating temperatures or extreme weather conditions, more frequent calibrations may be necessary. Such conditions can lead to faster sensor drift, resulting in inaccurate temperature readings and ultimately affecting system performance. Regular calibration helps maintain accuracy and ensures the control system effectively responds to changes in temperature.

Additionally, observing anomalies in temperature readings may prompt a recalibration before the next scheduled maintenance. Ensuring sensors remain accurate is crucial for the longevity and functionality of the solar temperature control box. Actively maintaining sensor integrity fosters consistent performance, making it essential for long-term operational success.

WHAT MATERIALS ARE BEST FOR HOUSING THE CONTROL BOX?

Selecting appropriate materials for housing the solar temperature control box is paramount for its durability and effectiveness. The choice of materials should consider environmental impact, insulation properties, and structural integrity. Generally, materials such as stainless steel and high-grade plastics are favorable due to their resistance to corrosion, temperature fluctuations, and UV radiation.

Stainless steel, in particular, offers robustness against mechanical impacts and extreme environmental conditions. It’s an ideal choice for long-term installations and harsh climates. However, the weight of metals must be balanced against installation constraints, particularly in rooftop applications.

On the other hand, high-density polyethylene (HDPE) or polycarbonate materials offer excellent thermal insulation and are often more lightweight, making them easier to handle during installation. These materials also provide resistance against UV rays, ensuring the control box remains functional over time without degradation. Ultimately, selecting the right materials involves assessing both the operational environment of the solar system and the expected lifespan of the components within the box.

FINAL REMARKS

Achieving a well-functioning solar temperature control box is not merely about installation; it encompasses understanding the science behind solar energy, continual assessment of operational needs, and the diligent execution of maintenance strategies. A well-designed temperature control system addresses critical concerns surrounding solar panel efficiency, operational longevity, and ecological considerations. By closely examining requirements, selecting suitable components, and creating an effective design, users pave the way for optimized solar energy solutions.

Moreover, implementing a robust control system involves a comprehensive understanding of the regulatory mechanisms necessary to govern temperature management in solar arrays. This requires both technical knowledge and hands-on experience, ensuring that all electronic and mechanical components operate synergistically.

With proper upkeep and monitoring, the solar temperature control box can not only enhance the performance of solar panels but also contribute to the broader goals of sustainable energy utilization. As renewable energy technologies continue to evolve, the integration of adaptive systems like temperature control boxes will play an essential role in ensuring the viability and sustainability of solar energy sources. Ultimately, this translates into both environmental benefits and economic advantages for users, as they capitalize on advancements in solar technology. Thus, investing in a solar temperature control system positions users favorably within this escalating field of ecologically responsible energy solutions.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-set-up-the-solar-temperature-control-box/