1. Understanding the retrofit process for energy storage entails multiple crucial elements, including 1) Assessment of existing infrastructure, 2) Selection of suitable energy storage technologies, 3) Integration challenges and solutions, 4) Economic feasibility and incentives.

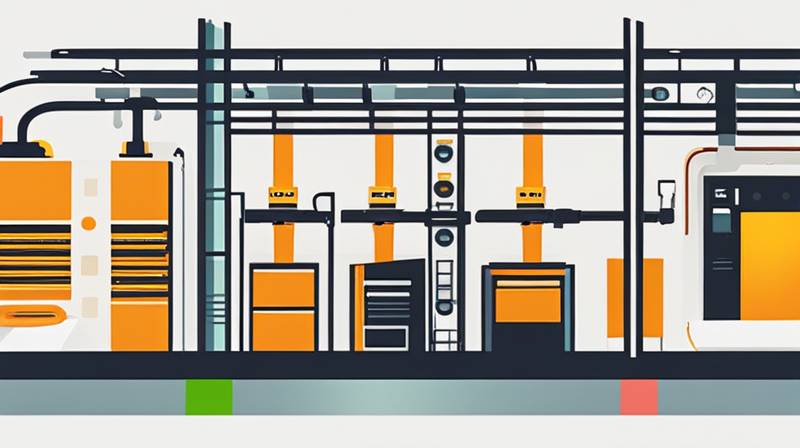

A critical aspect in this holistic endeavor is the assessment of the existing infrastructure, which can vary significantly in design, age, and operational efficiency. This necessitates a meticulous examination of the current electrical systems, load patterns, and energy consumption metrics. Factors such as physical space limitations, production processes, and maintenance protocols must also be evaluated to determine how energy storage can be effectively incorporated without disrupting existing workflows.

Moreover, selecting appropriate energy storage solutions, such as lithium-ion batteries, pumped hydro storage, or flywheels, requires an understanding of the specific energy demands of the facility. Each technology presents distinct advantages and drawbacks, necessitating comprehensive analysis to determine which system can yield the most significant benefits for a particular industrial application.

1. ASSESSMENT OF EXISTING INFRASTRUCTURE

When considering retrofitting an industrial facility with energy storage systems, the initial step involves a thorough evaluation of the current infrastructure. This encompasses an analysis of electrical systems, load characteristics, and operational efficiencies. Industrial plants often vary greatly in design, and therefore, tailoring the retrofitting process to the unique layout and purpose of the facility is paramount.

Conducting an energy audit is essential, as it provides critical insights into how energy is consumed throughout the facility. This audit can reveal patterns of energy use, peak demand times, and areas where energy efficiency may be improved. For example, identifying processes that consume excessive amounts of energy during peak periods can help in determining when to deploy energy storage solutions.

Furthermore, the reliability of existing electrical systems must be scrutinized. Upgrading outdated systems may be necessary to support the integration of new energy storage technologies. This phase also includes evaluating potential physical space constraints, which can limit the options for energy storage system installation. Understanding these limitations is vital for successful project planning.

ENVIRONMENTAL IMPACTS AND REGULATORY CONSIDERATIONS

A discussion on the environmental implications of retrofitting industrial facilities with energy storage technologies is pivotal. Regulatory frameworks often dictate how energy is utilized and can incentivize or penalize businesses based on their energy usage patterns. Assessing the environmental footprint of operations may also guide the choice of energy storage systems.

Additionally, compliance with environmental standards must be incorporated into the retrofitting strategy. This can include considerations for emissions, waste management, and resource conservation. By aligning with local and national regulations, companies can enhance their public image and advance sustainability goals, potentially attracting environmentally-conscious clients and investors.

2. SELECTION OF SUITABLE ENERGY STORAGE TECHNOLOGIES

Once the existing infrastructure has been thoroughly assessed, attention must turn to selecting suitable energy storage technologies. There are several energy storage solutions available, each with its own attributes, efficiencies, and applications. Understanding the specific energy needs of a facility is crucial to making the best selection among technologies such as battery systems, flywheels, pumped hydro storage, and compressed air energy storage.

Lithium-ion batteries have gained significant traction in recent years due to their high energy density and rapidly falling costs. These systems are particularly advantageous for applications that require fast response times and high cycle life. Conversely, pumped hydro storage is a well-established technology, offering substantial capacities and long-duration storage capabilities, though its feasibility is often limited by geographical constraints.

When evaluating technology options, one must consider not only performance metrics but also long-term reliability and maintenance requirements. Each storage technology comes with different operational lifetime expectations and maintenance challenges. Thus, evaluating the overall life-cycle costs, including installation, operation, and potential decommissioning, will inform stakeholders of which systems provide the best value in the long run.

ECONOMIC CONSIDERATIONS

Economics plays a significant role in determining the most appropriate energy storage technology. Capital expenditures (CAPEX) must be weighed against operational expenditures (OPEX) and potential savings resulting from operational efficiency. Energy storage systems can have high initial costs; therefore, understanding the return on investment (ROI), payback periods, and overall financial impacts is crucial.

A detailed financial analysis should include potential incentives and rebates provided by governmental or regulatory bodies designed to encourage the adoption of energy storage systems. These financial mechanisms can offset initial costs and significantly improve the economic feasibility of such projects. Understanding the full scope of incentives available can motivate decision-makers to pursue more ambitious energy storage projects.

3. INTEGRATION CHALLENGES AND SOLUTIONS

Integrating energy storage systems within existing industrial frameworks presents numerous challenges. Electrical grid compatibility and the interconnection of energy storage systems with existing power systems can be complex and often require specialized expertise. Existing infrastructure may not be designed to handle the unique characteristics of energy storage, resulting in engineering challenges that require careful planning and execution.

Furthermore, the operational protocols of industrial facilities must be adapted to incorporate the functionality of energy storage systems. This involves modifying processes to leverage energy stored during off-peak hours and deploying it when demand surges. Proper configuration and programming of control systems are paramount to ensure seamless operation and realize cost-saving opportunities.

In addition to technical challenges, workforce training is required to ensure that personnel are equipped to handle the nuances of new energy storage systems. Education and training programs can help workers understand how to operate and maintain new technologies, thus minimizing disruptions during the transition phase. A well-prepared workforce enhances the overall success of the retrofitting endeavor.

STRATEGIES FOR SUCCESSFUL INTEGRATION

Strategizing successful integration involves creating comprehensive plans that address potential challenges while emphasizing flexibility for future expansions. Engaging stakeholders early in the process can help facilitate smoother communication and dynamic problem resolution. Regular interaction between management, technical experts, and staff can help identify potential pitfalls and develop solutions proactively.

Furthermore, pilot projects can be valuable in demonstrating the effectiveness of energy storage systems prior to full-scale implementation. Such trial runs provide opportunities to fine-tune processes and mitigate risks associated with common integration challenges. By gradually rolling out energy storage solutions, companies can foster an atmosphere of innovation that embraces gradual upgrades and adaptations.

4. ECONOMIC FEASIBILITY AND INCENTIVES

Economic feasibility forms a cornerstone of the retrofitting process, impacting decisions regarding energy storage system adoption. Conducting thorough financial analyses enables stakeholders to make informed choices regarding capital investment and operational improvements. An understanding of financial dynamics will reveal the real costs associated with energy storage systems versus projected savings from energy efficiency.

In addition to CAPEX and OPEX analysis, exploring funding opportunities, such as government grants, low-interest loans, and tax incentives, can significantly alter financial calculations. Many local governments and international entities are offering financial incentives to companies adopting greener technologies, including energy storage. Identifying and securing such support can enhance the overall financial outlook and propel the retrofitting project into a more favorable light.

The evaluation of potential savings must also extend beyond the boundaries of energy costs. Improvements in operational efficiency can yield unforeseen benefits, including fewer maintenance demands, enhanced system reliability, and improved environmental compliance. These factors cumulatively bolster the case for retrofitting existing industrial facilities with energy storage systems, making them not only a sustainable choice but also a financially sound investment.

5. IMPLEMENTATION STRATEGIES

Successful implementation of retrofitting projects hinges on robust project management techniques that span the entire timeline from planning through execution. Clear timelines, milestone definitions, and performance metrics will provide direction throughout the process. Project management tools, like Gantt charts and Agile methodologies, can offer structure to complex tasks, fostering accountability and communication among team members.

Furthermore, ongoing monitoring and assessment protocols must be established to track the performance of installed energy storage systems. Utilizing software tools that gather data on system performance can provide critical insights needed to optimize operation and maintenance. These reports can guide decision-making and future upgrades, ensuring that the project continues to yield value over the long term.

FREQUENTLY ASKED QUESTIONS

WHAT IS THE MAIN BENEFIT OF ENERGY STORAGE SYSTEMS IN INDUSTRIAL SETTINGS?

Energy storage systems provide numerous advantages to industrial facilities, but perhaps the most significant is their capacity to enhance energy efficiency. By storing energy during periods of low demand and releasing it during peak usage times, companies can significantly reduce their energy costs. This practice, known as demand charge management, can lead to substantial savings as utilities often impose higher charges during peak usage.

In addition to cost savings, energy storage systems can also enhance the reliability of power supply. During grid outages or fluctuations, having a dedicated source of energy can keep operations running smoothly. Furthermore, this inherent reliability aids industries looking to adopt renewable energy sources, creating a balance between intermittent supply and consistent demand. Subsequently, energy storage technologies will enable businesses to utilize locally sourced renewable energy like solar or wind, aligning with sustainability goals and reducing reliance on fossil fuels.

WHAT CHALLENGES DO INDUSTRIAL FACILITIES FACE WHEN RETROFITTING WITH ENERGY STORAGE?

There are various challenges associated with retrofitting industrial facilities with energy storage systems, starting with the integration of new technologies into existing infrastructure. Managers may encounter hurdles related to space constraints, compatibility with current electrical systems, and unexpected operational disruptions that require careful navigation.

Additionally, the initial outlay for capital investment is often considerable, deterring stakeholders from proceeding. This is compounded by the complexity of selecting the correct energy storage technology. Financial implications, including maintenance and operational costs, must also be taken into account to determine long-term feasibility. Proper planning, stakeholder engagement, and extensive financial analyses can mitigate many of these challenges, ensuring that the retrofitting goals are satisfactorily met while minimizing operational disruptions.

HOW DO INCENTIVES IMPACT THE RETROFITTING PROCESS WITH ENERGY STORAGE?

Incentives granted by governmental or local authorities can drastically improve the viability of retrofitting projects with energy storage technologies. These financial advantages—such as tax credits, grants, and rebates—can significantly reduce the initial capital expenditures required for such systems, making it easier for companies to justify investments.

In addition to upfront savings, incentives can also aid companies in achieving a more rapid return on investment. The availability of these financial mechanisms can lead to a more favorable evaluation of project feasibility, allowing businesses to allocate funds toward additional initiatives. Companies that actively pursue these incentives not only tap into essential funding streams but also contribute to broader energy transition goals, promoting local and national efforts toward sustainability.

The implementation of energy storage systems within existing industrial infrastructures is transformative, offering substantial benefits while posing unique challenges. Effective strategy is paramount for overcoming hurdles in assessment, selection, and integration of energy storage technologies. Determining the right fit for specific facilities while accounting for existing constraints requires a meticulous approach grounded in comprehensive analysis.

Ultimately, a holistic understanding of both the operational and economic landscapes allows decision-makers to craft a roadmap for success. By narrowing in on effective project management and engaging all stakeholders throughout the process, businesses foster a collaborative environment essential for the seamless retrofitting of energy storage systems. The future of industry is in adopting sustainable solutions, and energy storage stands at the forefront of this evolution, delivering reliability, efficiency, and environmental integrity within industrial operations.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-retrofit-existing-industrial-facilities-with-energy-storage-systems/