To address the topic of solar controller repair, the following insights will provide a comprehensive guide. 1. Understanding the Problem Thoroughly, 2. Gather Necessary Tools and Materials, 3. Follow Step-by-Step Repair Procedures, 4. Test the Controller After Repair. Each section will delve into the intricacies of the repair process, ensuring clarity and ease of understanding.

1. UNDERSTANDING THE PROBLEM THOROUGHLY

Before embarking on any repair endeavor, it is imperative to grasp the nuances of what a solar controller does and the common issues it may encounter. A solar charge controller regulates the voltage and current coming from the solar panels to the battery, ensuring that the batteries remain charged without the risk of overcharging. Identifying the symptoms of a malfunction is crucial. Common issues may include the controller not charging the batteries, an incorrect voltage reading, or the system shutting down unexpectedly. A detailed understanding of these symptoms can guide the repair process effectively.

Furthermore, it is essential to know the type of controller being used, as there are various models and technologies on the market, such as Pulse Width Modulation (PWM) or Maximum Power Point Tracking (MPPT) controllers. Each type has its specific characteristics and nuances, thereby influencing the approach needed for effective repair. This knowledge significantly impacts the accuracy of the diagnosis and the subsequent steps taken to fix the problem.

2. GATHER NECESSARY TOOLS AND MATERIALS

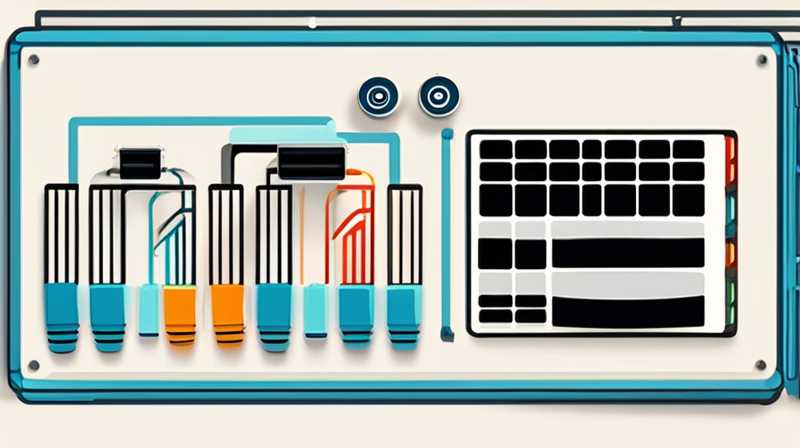

Successful repair hinges on the availability of proper tools and materials. Depending on the specific issue diagnosed, different tools may be required. Basic hand tools such as screwdrivers, wrenches, and pliers are essential for disassembling the solar controller. Additionally, multimeters are vital for testing voltage, current, and continuity. Having a soldering iron may also be necessary for repairing any circuit issues that require connections to be re-established.

Moreover, having access to replacement parts can be crucial. Components such as fuses, diodes, or capacitors may need to be replaced if they are found to be faulty during the repair process. Prior research can reveal the specific parts needed for the particular model of the solar controller, ensuring that the repair is not only efficient but also effective. Ensuring that all tools and parts are on hand before beginning the repair process will streamline the operation.

3. FOLLOW STEP-BY-STEP REPAIR PROCEDURES

Upon gathering the necessary tools, the next phase involves following a systematic approach to repair. This process typically commences with safely disconnecting the solar controller from both the solar panels and batteries to prevent any accidental electrical shocks during repair. It is advisable to unplug the device and wait for a few moments to ensure that all capacitors are discharged before beginning any disassembly.

Once the controller is disconnected, the initial inspection begins. Look for visible damage, such as burn marks or signs of overheating on circuit boards. If accessible, the casing should be opened carefully without causing further damage to internal components. A thorough examination of solder joints can reveal cold or broken connections, which should be re-soldered as necessary. For controllers showing signs of corrosion, especially in coastal areas, cleaning with isopropyl alcohol may be beneficial.

After the inspection, it is crucial to assess any faulty components identified during the inspection. If components such as diodes or capacitors are found defective, replacement is necessary. Make sure to choose components with specifications matching or exceeding the originals for reliable performance. Once replacements are made, reconstruct the connections carefully, validating that all are secure before closing the casing. This procedure not only restores functionality but also enhances the longevity of the solar controller.

Testing is paramount after completing the repair. Reconnect the solar controller to the panels and batteries, observing for proper charging functionality. Utilize a multimeter to check voltage output and system behavior. Ensure that all connections are secure, and test under varying conditions to confirm that the repair is successful. Monitoring the controller over a few days or weeks will provide further insights into its stability.

4. TEST THE CONTROLLER AFTER REPAIR

Testing a repaired solar controller demands careful monitoring to ensure effectiveness and reliability. Begin by reconnecting the system, ensuring that all connections are tight. Then, observe the controller’s behavior over several hours to ascertain whether it charges the batteries appropriately. Utilize a multimeter to measure the input from the solar panels and output to the batteries frequently.

It is essential to monitor for signs of overheating or irregular indicators that were present prior to the repair. If the controller displays expected behavior and charging performance is stable, this indicates a successful repair. However, if issues persist, further diagnostic measures must be taken, including revisiting the working conditions and connections within the controller. Documenting test results may also help identify trends or patterns that signal recurring issues, providing a more extensive overview of the controller’s reliability post-repair.

FREQUENTLY ASKED QUESTIONS

WHAT ARE THE COMMON SYMPTOMS OF A FAULTY SOLAR CONTROLLER?

Dealing with a faulty solar controller can be daunting without an understanding of its common symptoms. Typically, the most noticeable signs include failure to charge batteries, erratic voltage readings on the display unit, or complete system shutdowns. In some instances, the LED indicators on the controller may blink in unusual patterns, suggesting an error state, or remain lit without changing, indicating a disconnect from its usual operational state.

Another symptom to watch for is unusual heat generation, which could suggest an underlying failure in the regulator or internal components. If the solar setup is performing poorly, with batteries not reaching full charge or discharging quickly, it may also imply that the controller is malfunctioning. Performing regular tests with a multimeter can help diagnose these issues, ensuring any remedial action is taken swiftly to prevent damage to both the solar panels and batteries.

HOW OFTEN SHOULD A SOLAR CONTROLLER BE MAINTAINED OR CHECKED?

Regular maintenance of a solar controller is crucial for ensuring optimal performance and longevity. It is recommended to conduct checks at least once every six months. This routine inspection includes cleaning terminals, checking connections for corrosion, and ensuring that the device is free from any debris or dust that may hinder its operation.

Additionally, in areas with harsh weather conditions, more frequent checks may be warranted. During these inspections, a careful eye should be kept on the state of the wiring and the physical condition of the solar controller. Testing the output regularly using tools like a multimeter can help track performance trends over time, allowing users to address minor issues before they become significant problems. Maintaining meticulous logs of maintenance activities can also aid in identifying any emerging patterns of wear and tear.

CAN A SOLAR CONTROLLER BE REPAIRED OR REPLACED?

Deciding between repairing or replacing a solar controller often depends on the extent of the damage and the cost-effective considerations surrounding the repair. If the controller shows minor faults, such as burned fuses or damaged connectors, these issues can typically be addressed with basic repairs, leading to an extended life cycle for the equipment. However, significant internal damage to circuit boards or critical components may not be justifiable when weighed against the cost of a replacement.

Furthermore, technological advancements may render older models less efficient, prompting users to consider replacement for enhanced performance and reliability. Consulting with experienced technicians to evaluate the condition of the solar controller can provide clarity on the best course of action. Ultimately, the decision should weigh repair costs, potential features of new models, and the current operational effectiveness of the existing unit.

FINAL REMARKS

Undoubtedly, successfully repairing a solar controller necessitates a comprehensive approach, beginning with a clear identification of the problem and followed by meticulous attention to detail during the repair process. Equipped with the right tools and a systematic strategy, anyone can navigate this challenge effectively. Observing proper safety measures throughout will safeguard both the individual performing the repair and the integrity of the solar energy system. Ultimately, regular maintenance, as well as periodic inspections, not only minimizes unforeseen issues but also maximizes the operational efficiency of the solar energy setup. Consistently monitoring performance metrics will foster a deeper understanding of the system and empower owners to make informed decisions regarding repairs or replacements in the future.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-repair-solar-controller/