Repairing a broken solar float involves several crucial steps. 1. Assess the damage, examine the solar panel, check the floatation mechanism, identify the power source, and gather necessary materials. A thorough inspection of the float is essential to determine the extent of the damage. 2. Replacing broken components requires understanding solar panel connections, understanding buoyancy issues, and utilizing waterproof adhesives. Each of these elements plays a vital role in ensuring the float operates efficiently once repaired.

The repair process involves carefully disassembling the float to access the damaged parts. 3. Proper reassembly is vital; pay close attention to water seals, weight distribution, and overall functionality. A common issue is ensuring that the solar panel receives sunlight adequately after repairs. 4. Test the float in a controlled environment before reintroducing it into its intended surroundings. This ensures that it functions correctly and that no other underlying issues remain unaddressed.

1. UNDERSTANDING THE COMPONENTS OF A SOLAR FLOAT

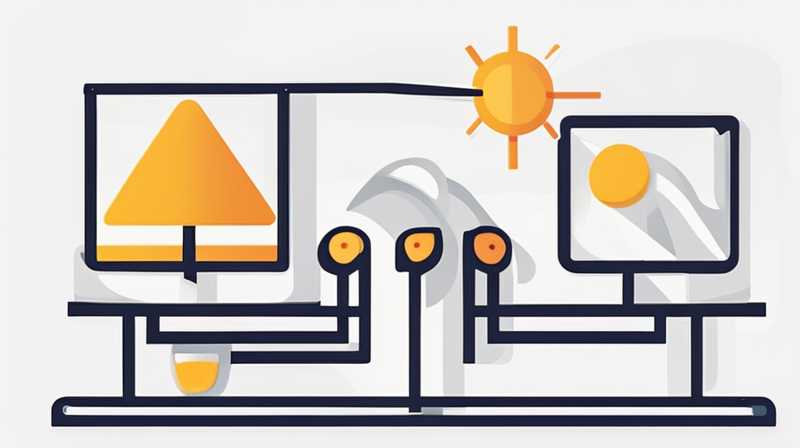

In order to effectively repair a broken solar float, it is essential to first grasp the functionalities of its various components. Solar floats typically consist of a solar panel, battery, flotation device, and electrical connections. The solar panel absorbs sunlight and converts it into electrical energy, which is stored in the battery.

The flotation device, often constructed from materials that ensure buoyancy, allows the float to remain on the surface of the water. Understanding how these components work together is crucial to diagnosing problems and implementing effective solutions. When one part malfunctions, it may affect the entire system. A deep understanding of these components will empower individuals to make informed decisions about repairs.

Before initiating repairs, a comprehensive examination of each component is necessary. Over time, solar panels can accumulate dirt and debris, diminishing their efficiency. Cleaning the solar panel is often the first step in addressing functionality issues. After cleaning, it becomes easier to check the battery and connections. If the battery has lost its ability to hold a charge, replacing it becomes the next logical step in the repair process.

2. ASSESSING THE DAMAGE

When a solar float is deemed “broken,” evaluating the extent of the damage becomes imperative. This assessment includes taking a meticulous look at the solar panel, battery life, mechanical components, and structural integrity. Often, the evidence of damage might be blatant, such as cracks in the float or burnt electrical parts.

For example, if cracks are observed on the solar panel, it is vital to understand if these are superficial or if they compromise the panel’s functionality. A simple hairline crack might not hinder performance, but a significant fracture may necessitate replacement. Similarly, checking for water ingress in the float’s internal components is essential. Water can cause significant damage to electrical connections, and remedying this promptly is critical for restoring functionality.

By conducting a thorough examination of each component, one can identify whether repairs or replacements are necessary. For complex electrical issues, a multimeter can determine whether electrical connections are operational. Distinguishing between various forms of damage will guide the repair process, ensuring that only the necessary parts are replaced or repaired.

3. GATHERING NECESSARY MATERIALS

Embarking on a repair process requires the right tools and materials to execute the job efficiently. Basic tools such as screwdrivers, waterproof adhesive, replacement batteries, and new solar panels may be necessary. Having these materials on hand avoids unnecessary delays during the repair.

Waterproof adhesive is particularly important for ensuring the float is sealed correctly. If cracks are present, applying a strong adhesive while following proper techniques can prolong the float’s life. It is crucial to utilize adhesives specifically designed for aquatic environments, as these can withstand prolonged exposure to water.

Furthermore, one may also need wiring tools for reconnecting electrical components. Electrical connections must be secure to prevent future power issues. In addition to tools, having safety equipment, such as gloves and goggles, is recommended to protect oneself while handling potentially fragile components.

One efficient approach is to compile a repair kit before beginning repairs. Being thoroughly prepared streamlines the repair process and mitigates frustrations arising from inadequate supplies. With the right materials collected and assembled, the next step is to initiate the hands-on repair process.

4. DISASSEMBLING THE FLOAT

Once the necessary materials are gathered, the next phase involves disassembling the float. Careful and systematic disassembly is essential to prevent additional damage. Begin by removing screws and securing them in a designated space to avoid misplacing them during the process.

During disassembly, pay attention to the order of the components. Each float may have a slightly different assembly, so keeping track of how parts fit together ensures a smoother reassembly later. As components are removed, take the opportunity to document any findings—this log can aid in identifying potential issues or parts that may need replacement.

After thorough disassembly, a meticulous inspection of every component should follow. Examine wiring for fraying or damage, check the integrity of connections, and assess the overall condition of the float. This comprehensive approach guarantees that hidden issues are uncovered prior to reassembling the float, setting the stage for a more effective repair.

5. REPLACING DAMAGED PARTS

After evaluating the disassembled float, addressing damaged components is crucial. Replacing damaged batteries is often necessary, as batteries have a finite life span. A corroded or worn-out battery will not retain sufficient energy to power the float, rendering it ineffective.

Installing a new solar panel might also be required in the event the existing one is fundamentally compromised. Carefully following the manufacturer’s specifications during installation guarantees proper functionality post-repair. In addition, when replacing components, ensure that proper seals are applied where necessary, especially around electrical connections, to prevent water ingress.

Once damaged parts are replaced, it’s advisable to conduct short tests before fully reassembling the float. Testing electrical connections and ensuring the panel receives power aids in verifying progress. This step allows for adjustments to be made if anything is not functioning correctly before final assembly.

6. REASSEMBLING THE FLOAT

With all repairs made and replaced parts installed, the reassembly of the float can begin. Following the disassembly log during this phase ensures that components are reattached in the correct order. Pay close attention to securing all screws and connections to prevent leakage or functional issues.

During reassembly, make sure that seals are properly placed. Ensuring that all joints are watertight is critical, as leaks can significantly hinder the float’s functionality. Often, fresh adhesive may be required on joints that initially sealed well but may have weakened over time.

Once the float is fully reassembled, its structural integrity should be carefully inspected one more time. Gently squeezing or rotating the float may provide insights into whether it is sound and secure. A reassurance checkpoint can save potential headaches, making it vital for confirming that all parts fit snugly.

7. TESTING THE REPAIRED FLOAT

After the float has been reassembled, conducting tests is fundamental to determine whether repairs have been successful. Testing allows one to assess buoyancy, solar charging capacity, and electrical functionalities. Begin testing in smaller, controlled water bodies to monitor how the float performs in actual conditions.

Place the float in the water and observe its buoyancy. If it sinks or tilts significantly, adjustments may be necessary to correct the weight distribution. Solar panels should be positioned correctly to receive sunlight; any obstruction can severely impair performance.

Monitoring the float over time provides further insight. Check whether it retains charge adequately and operates efficiently. In the case of preventing electrical failures, consider using voltmeters to gauge battery levels consistently. These checks will ensure the float operates as expected after repairs.

FREQUENTLY ASKED QUESTIONS

WHAT SHOULD I DO IF MY SOLAR FLOAT DOESN’T CHARGE?

If a solar float fails to charge, several troubleshooting steps can identify the issue. Firstly, examine the solar panel for obstructions. Dirt, leaves, or other debris can significantly diminish its ability to absorb sunlight. Cleaning the panel gently with a soft cloth can restore its power-generating capacity.

Next, inspect the connections leading from the solar panel to the battery. Loose or corroded wires can disrupt power transfer. Tightening these connections may solve the problem. In addition, check whether the battery has reached its lifespan. If the battery does not hold charge anymore, replacing it is necessary.

Regular maintenance of the entire float system can prevent such issues. Keep the solar panel clean and inspect the components periodically. This proactive approach will minimize the likelihood of charging problems arising in the future.

HOW CAN I ENSURE MY SOLAR FLOAT LASTS LONGER?

To maximize the lifespan of a solar float, consistent maintenance and proper usage are essential. Begin by regularly cleaning the solar panel to ensure it operates at peak efficiency. Accumulated dirt and debris can significantly affect its performance, so routine cleanings will help maintain power generation.

In addition, inspect seals and joints for signs of wear. Updating seals as needed prevents water from infiltrating the float and damaging internal components. Keep an eye on battery life and replace batteries before they fail to prolong the float’s functionality.

Ultimately, employing preventive measures will keep the system operating smoothly. Proper storage during harsh weather conditions can also contribute to a longer lifespan. Storing the float in a protected area during extreme conditions will preserve its components and continue its effective performance.

WHAT MATERIALS ARE BEST FOR REPAIRS?

Selecting the right materials for the repairs is vital to ensuring the float’s functionality and longevity. When looking for adhesives, opt for waterproof options specifically designed for outdoor and aquatic applications. This will ensure that repairs hold against constant exposure to water without deteriorating.

Moreover, when replacing any electrical components, use high-grade materials. This includes quality wiring, robust batteries, and reliable connectors. Investing in superior materials will make the float more resilient and reduce the frequency of future repairs.

Lastly, consider using buoyant materials while repairing physical components. This enhances the overall buoyancy and structural integrity of the float, ensuring it remains effective while on the water. By choosing appropriate materials, one can create a more durable and efficient solar float.

REPAIRING A BROKEN SOLAR FLOAT REQUIRES THOUGHTFUL CONSIDERATION AND ATTENTION TO DETAIL. Eager individuals must begin by assessing the damage to discern if repairs are feasible. Gathering the necessary supplies is paramount, creating a more streamlined process once the float is disassembled. Replacing any damaged parts is crucial, as well as ensuring watertight seals during reassembly. Testing after repairs is important to ascertain functionality before returning the float to its intended use.

In summary, understanding the ins and outs of repairing solar floats is not only beneficial but can save time and resources. Regular maintenance practices will yield a longer lifespan for these devices and enhance their performance while in service. Thomas Edison’s quote regarding invention emphasizes the value of persistence—similarly, the repair process of solar floats rewards patience and thoroughness. Taking the necessary time to evaluate and execute repairs leads to greater success in the long run, instilling confidence in the float’s capability to perform efficiently.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-repair-a-broken-solar-float/