1. Identify the Problem, 2. Gather Necessary Tools, 3. Follow Repair Steps, 4. Test the Controller

When faced with a malfunctioning solar controller, the initial step involves identifying the exact issue. Common problems include failure to charge batteries, erroneous readings, or physical damage. Once you’ve pinpointed the issue, the next phase is to gather the appropriate tools, which typically consist of a multimeter, screwdrivers, soldering iron, and potentially replacement parts. The subsequent actions include carefully disassembling the device to inspect internal components, making necessary repairs such as soldering loose connections or replacing damaged parts, and reassembling everything with attention to detail. After completing repairs, thorough testing is essential to ensure functionality. It is crucial to monitor performance over several days, as intermittent issues may require additional attention.

1. UNDERSTAND THE WORKINGS OF A SOLAR CONTROLLER

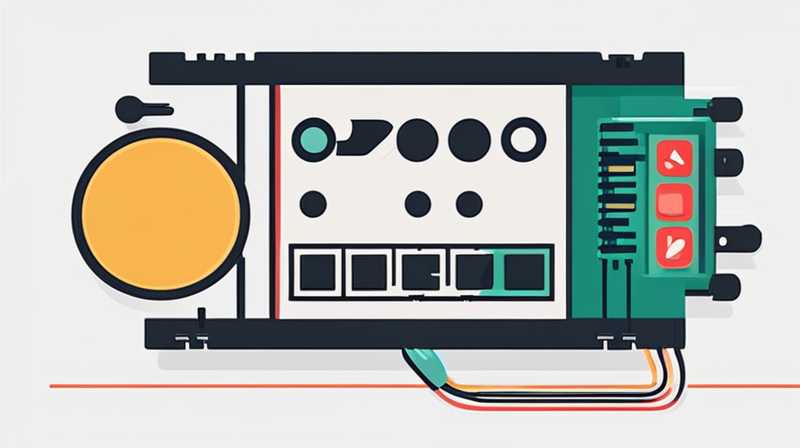

To effectively address the repair process, a comprehensive understanding of the solar controller’s functionality is imperative. Solar controllers act as intermediaries between solar panels and batteries, ensuring the efficient operation of solar energy systems. They primarily regulate the voltage and current that flow into and out of the batteries to prevent overcharging or excessive discharging.

In typical scenarios, solar controllers vary by technology: PWM (Pulse Width Modulation) or MPPT (Maximum Power Point Tracking). Each type has its own mechanism for voltage regulation. PWM controllers adjust the voltage by rapidly switching on and off, while MPPT controllers optimize the energy harvested from solar panels by converting excess voltage into additional current. Familiarizing oneself with these functions will make it easier to identify the root cause of any malfunction and to perform the necessary adjustments and repairs meticulously.

2. GATHER THE PROPER TOOLS AND MATERIALS

Before undertaking repairs, ensuring that you have the right tools and materials can significantly influence both the process and the outcome. Essential tools include a multimeter for testing voltage and continuity, screwdrivers for disassembling the controller, and a soldering iron for reconnecting wires or components. Additionally, having replacement parts on hand, such as fuses, connectors, or circuit boards, can expedite the repair process.

It can also be beneficial to use a workbench with adequate lighting to facilitate detailed examination and repairs. A clean, organized workspace can greatly reduce the likelihood of losing small components or making errors during assembly. Understanding how each tool functions and how it applies to the parts within the solar controller is vital for safety and efficiency.

3. DIAGNOSE THE ISSUE

Once the necessary tools are gathered, the next step is to diagnose the problem thoroughly. Carefully inspect the solar controller for visible signs of damage, such as burnt components, loose connections, or corrosion. Testing the voltage at various points within the controller using a multimeter can pinpoint where the fault lies. This allows for a strategic approach in addressing only the defective areas rather than replacing the entire device.

Focusing on the current flow involves analyzing the path from the solar panel to the batteries. Any irregularities in readings may suggest a problem with wiring or with the controller itself. It’s crucial to understand that intermittent failures can occur; thus, thorough testing over time is necessary to assess the durability of any repair made and to avoid repeated issues.

4. PERFORMING THE REPAIR

After diagnosing the issue accurately, you can proceed with the repair process. Depending on the problem, this may involve resoldering loose connections, replacing damaged capacitors, or swapping out entire circuit boards. It’s vital to be precise and cautious—errors during this stage can further damage the controller or create safety hazards.

When soldering, ensure that the surfaces are clean and that you use the correct type of solder. The right temperature settings on the soldering iron will also prevent damage to sensitive components. If circuits are involved, tracing the pathways accurately can eliminate guesswork and make your repair efforts more straightforward and effective.

5. REASSEMBLY AND TESTING

Following the repairs, carefully reassemble the solar controller by reversing the process of disassembly. As you put the unit back together, double-check that all components are properly aligned and securely fitted. Pay attention to any adhesive seals, screws, or clips that may need to be tightened or resealed to protect against environmental factors.

After reassembly, the next phase is rigorous testing. This involves connecting the solar panels and batteries to the controller and monitoring its performance under various conditions. Ensure that charging rates are within acceptable parameters, and keep an eye out for abnormal sounds or heats arising from the unit. Testing over several days can provide insights into the stability of the repair and whether further adjustments may be necessary.

6. MAINTAINING THE SOLAR CONTROLLER

To prevent future breakdowns, establishing a routine maintenance schedule can be beneficial. Regular inspections of the controller for signs of wear or damage can help identify potential issues before they exacerbate. Furthermore, cleaning terminals and connections from corrosion ensures a consistent flow of energy and prolongs the controller’s lifespan.

Documentation of any repairs made, including details of parts replaced or adjustments performed, can also be valuable. This information can aid in troubleshooting should any similar issues arise in the future. Employing a proactive maintenance approach ensures that your solar energy system operates efficiently over its expected lifespan.

COMMON TROUBLESHOOTING TIPS

When dealing with persistent problems, some general troubleshooting steps can be helpful. For example, if the controller appears unresponsive, check for blown fuses or tripped breakers within the system setup. Ensuring that all connections are tight and that the wiring is intact can also eliminate simple yet easy-to-miss issues. If the controller does not read the voltage correctly, recalibrating the device may resolve discrepancies.

In the event that repairs do not lead to expected outcomes, contacting a professional may be necessary. Some faults may extend beyond user-serviceable components, requiring specialized knowledge for safe and effective resolution.

FREQUENTLY ASKED QUESTIONS

WHAT IS A SOLAR CONTROLLER?

A solar controller, often referred to as a solar charge controller, serves as a critical component in a photovoltaic energy system. Its primary role is to regulate the charging of batteries from solar panels, ensuring that they are charged safely and efficiently. The device prevents overcharging, which can lead to battery damage, while also ensuring that batteries do not discharge too low, preserving their lifespan.

There are two primary types of solar controllers: Pulse Width Modulation (PWM) and Maximum Power Point Tracking (MPPT). PWM controllers are straightforward and cost-effective technologies, while MPPT controllers are more efficient and are often used in systems where optimizing energy production is crucial. Understanding the function of solar controllers can help you recognize their importance in maintaining the health and performance of your solar energy system.

HOW DO I KNOW IF MY SOLAR CONTROLLER IS FAULTY?

Identifying the signs of a malfunctioning solar controller can save both time and money in repairs. Common indicators include erratic readings on the display, failure to charge the batteries, or unusual sounds from the controller itself. A practical approach to diagnosing these issues involves using a multimeter to assess voltage levels at various points in the system.

You might also notice that the batteries are not holding a charge or that they deplete quickly even after being charged. If visual inspection reveals burnt components or loose connections, these can also signal a defective solar controller. In any case, systematic testing will help confirm whether the controller needs repair or replacement.

CAN I REPAIR A SOLAR CONTROLLER MYSELF?

Many individuals with basic technical skills can attempt to repair a solar controller themselves. However, this often requires a clear understanding of electronics and specific tools for the task, such as a multimeter and soldering iron. If one feels comfortable diagnosing and addressing the problems, many resources such as manuals, online tutorials, and forums provide guidance for those looking to resolve issues independently.

That said, if you encounter extensive damage or are uncertain about the appropriate repair steps, consulting a professional may be the best option. Seeking expert attention ensures not only the effective resolution of issues but also the safety and longevity of the solar energy system as a whole.

Repairing a broken solar controller can be a manageable task when approached correctly. Establishing a clear understanding of the solar controller’s function and mechanisms makes it easier to identify issues and respond appropriately. With the right tools and familiarity with troubleshooting processes, many repairs can be undertaken independently, saving both time and resources. Ongoing maintenance contributes significantly to the longevity and efficiency of solar energy systems. Regular inspections, alongside thorough monitoring, can help anticipate problems before they manifest significantly. Exploring reliable solutions and maintaining a commitment to understanding the technology ensures that solar energy systems continue to function smoothly and effectively throughout their lifespan. Ultimately, a proactive approach to repair and maintenance creates a sustainable relationship with solar energy technology, aligning with broader goals of resource conservation and environmental stewardship.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-repair-a-broken-solar-controller-2/