How to pull monocrystalline silicon solar panels

1. Monocrystalline silicon solar panels are manufactured from a single continuous crystal structure, favored for their efficiency and space-saving capabilities. 2. The production process involves the Czochralski method or the float zone technique, which impacts both quality and performance. 3. Various factors such as installation techniques and environmental conditions must be considered during the pulling process to optimize output. 4. Proper handling and safety measures are crucial to prevent damage throughout the entirety of the procedure.

1. UNDERSTANDING MONOCRYSTALLINE SILICON

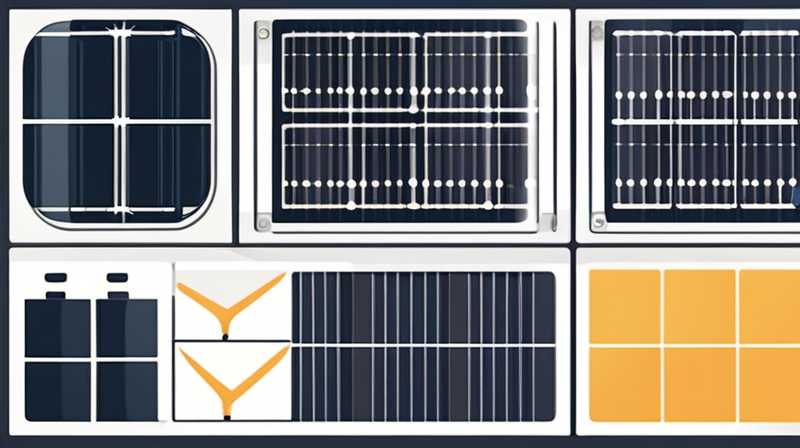

Monocrystalline silicon is considered the highest efficiency solar panel technology available today, primarily due to its unique manufacturing process. This procedure involves utilizing a single crystal lattice structure, which allows for uninterrupted electron flow and higher energy conversion rates. The production process typically follows two predominant techniques: the Czochralski method and the float zone method. Each method incurs different levels of construction quality and ultimately affects the panel’s long-term performance.

The Czochralski method entails melting silicon in a quartz crucible to provide the necessary heat. A seed crystal is slowly drawn out, forming larger crystalline structures as it cools. This technique yields high-purity silicon which translates into superior photovoltaic efficiency. In contrast, the float zone method utilizes gaseous silicon and does not involve melting, allowing for even higher purity levels. Understanding these production methods is foundational to grasping how to effectively pull monocrystalline silicon solar panels.

2. TECHNIQUES FOR PULLING PANELS

Engaging in the process of pulling monocrystalline silicon solar panels involves various methodologies to achieve optimal results. Selecting the appropriate technique is critical, as it determines not only the efficiency of the panel but also its longevity and durability. Factors such as temperature control, pulling speed, and environmental conditions play significant roles in determining the success of the operation.

For effective temperature management, precise monitoring must be implemented throughout the pulling phase. This means using thermocouples or other temperature-sensing devices to ensure that the crystalline structure does not experience thermal shock or stress. Acquiring the right pulling speed is equally critical; if pulled too quickly, the crystalline alignment may suffer, resulting in defects and inefficiencies. Engaging in slow, controlled pulling allows for uniformity and a higher quality final product.

3. SAFETY MEASURES

Proper safety protocols must be established throughout the pulling process to mitigate risks associated with high-temperature environments. Mandatory protective gear, including gloves, goggles, and heat-resistant clothing, should always be worn to prevent injuries. Regular audits and check-ups of equipment should also be performed, ensuring everything operates within safe parameters to avoid accidents.

Training personnel on these safety protocols is equally important. Staff members must thoroughly understand the hazards involved, which can range from burns due to hot surfaces to electrical shocks from malfunctioning machinery. Routine emergency drills should also be held to prepare all workers for potential risks, ensuring that a cohesive safety culture is effectively fostered on-site.

4. INSTALLATION CONSIDERATIONS

When it comes to actual panel installation, certain considerations must be taken into account to maximize performance. Orientation and spacing play a crucial role in ensuring panels receive adequate sunlight throughout the day. Choosing the right angle can drastically affect energy capture, thus requiring comprehensive geographical analysis prior to setting up installations.

Another significant factor is the environmental conditions of the installation area. Elements such as cloud cover, pollution levels, and seasonal variations can impact solar panel performance. Using monitoring software can help assess these conditions at various times, allowing for optimizations that may increase overall efficiency and energy production.

5. LONG-TERM MAINTENANCE

After successfully pulling and installing monocrystalline silicon solar panels, the focus then shifts to their long-term maintenance. Regular cleaning routines are essential to remove dirt, dust, and environmental debris that can obstruct sunlight absorption. Depending on the environment, cleaning frequencies may need to be increased to maintain peak performance.

Additionally, monitoring the system’s output helps to identify efficiency drops that might indicate underlying issues. Implementing advanced diagnostic systems can provide alerts for maintenance needs before they become critical, ensuring a longer operational life for the panels.

FAQs

WHAT ARE MONOCRYSTALLINE SILICON SOLAR PANELS?

Monocrystalline silicon solar panels are photovoltaic devices made from single-crystal silicon, known for their efficiency and power output. They are characterized by their uniform color and rounded edges, often classified as higher-end panels due to their cost and performance. Panels typically convert around 15-20% of solar energy into usable electricity, depending on the brand and technology utilized. The higher efficiency is largely attributed to the manufacturing process, which results in a more organized arrangement of silicon atoms, allowing electronics to flow unimpeded. This organization leads to better energy conversion efficiency than other technologies, such as polycrystalline silicon panels which are generally less efficient due to crystalline imperfections.

WHAT IS THE AVERAGE LIFESPAN OF MONOCRYSTALLINE SOLAR PANELS?

The lifespan of monocrystalline solar panels typically ranges from 25 to 30 years, although some manufacturers offer warranties extending beyond this timeframe. Factors that contribute to this longevity include the quality of materials used, specific manufacturing processes, and proper installation techniques. Additionally, maintenance plays a critical role in determining how long these panels remain efficient and functional. Regular inspections and cleaning can minimize the accumulation of dirt and debris, which are notorious for reducing solar efficiency if left unchecked. Furthermore, several advancements in solar technology continually improve panel durability, meaning that more recent models might even surpass the typical lifespan expectations found in reviews.

HOW DOES WEATHER AFFECT SOLAR PANEL PERFORMANCE?

Weather conditions have a substantial impact on the performance of monocrystalline solar panels. Cloud cover, heavy rainfall, and snowy conditions can significantly diminish the amount of sunlight received, which directly affects energy output. While these panels perform better under direct sunlight, they still capture energy efficiently in diffuse light environments. Hence, some solar systems utilize monitoring technology to account for weather fluctuations and optimize their operation accordingly. It’s also worth noting that extreme temperatures can influence efficiency; high temperatures can reduce output, while cold weather may enhance performance. Thus, geographical location and seasonal variations must be factored into energy yield predictions and system design.

In sum, acquiring the ability to effectively pull monocrystalline silicon solar panels requires a nuanced understanding of both the production process and the various considerations that influence their performance. The initial extraction of monocrystalline silicon from raw materials sets the stage for high-energy performance, yet it necessitates adherence to specific techniques that dictate quality and longevity. Ensuring the proper handling and safety measures throughout the entire procedure is paramount and cannot be understated. Furthermore, once installed, panels demand ongoing maintenance, attention to environmental factors, and the implementation of technology to monitor performance. By focusing on these critical aspects, system owners can maximize the benefits derived from their solar investments, contributing ultimately to a sustainable future in renewable energy.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-pull-monocrystalline-silicon-solar-panels-2/