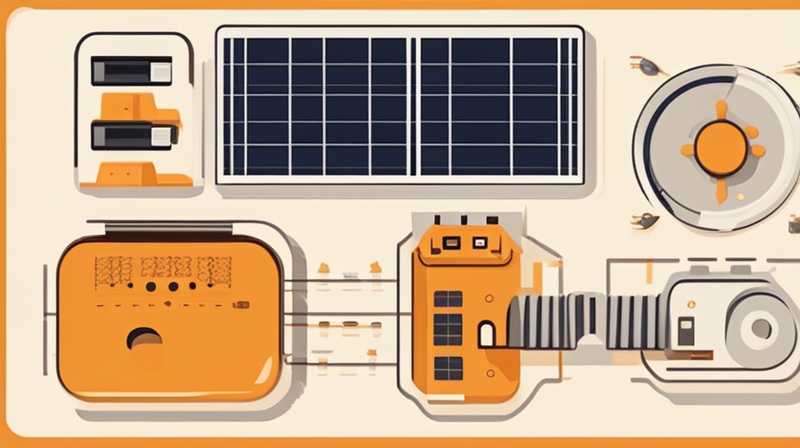

Preventing short circuits in solar cells involves several essential strategies. 1. Use high-quality materials and components, 2. Implement proper installation techniques, 3. Conduct regular maintenance and inspections, 4. Employ suitable protective measures against environmental factors. Focusing on high-quality materials is particularly crucial; low-quality components can result in increased risks of failure and will ultimately compromise the efficiency of the solar power system. This requires selecting reputable manufacturers who adhere to stringent quality standards.

1. UNDERSTANDING SHORT CIRCUITS IN SOLAR CELLS

Short circuits in solar cells occur when an unintended connection forms within the system, leading to excess current flow. This situation compromises not only the functionality of individual solar cells but also impacts the entire photovoltaic (PV) system’s output. The root causes of short circuits can be manifold, ranging from damaged wiring to connectors exposed to moisture.

One of the prevalent causes relates to the installation process, wherein improper handling and a lack of diligence can result in physical damage to the cells and their connections. Additionally, environmental factors—such as exposure to extreme weather conditions—can also lead to a premature breakdown of materials. Recognizing these underlying issues provides insight into how to effectively mitigate the risks associated with short circuits.

Through careful analysis, it’s essential to understand that short circuits can drastically reduce energy efficiency. Among solar power systems, a short circuit not only limits the power that can be generated but can also introduce the potential for hazardous situations, such as overheating or the risk of fire. Proper preventive measures can significantly minimize such scenarios and enhance the overall sustainability of solar energy solutions.

2. MATERIAL QUALITY AND COMPONENT RELIABILITY

Quality of materials plays a pivotal role in the longevity and efficiency of solar cells. When choosing components, it is vital to prioritize suppliers with a proven track record. This is because subpar materials can lead to increased susceptibility to environmental factors, exacerbating the risk of short circuits.

Components such as wires, connectors, and inverter circuitry need to be evaluated with due diligence. Using UV-resistant materials for wires and connectors is essential; these materials can withstand prolonged exposure to sunlight without degrading. Furthermore, weatherproofing seals and coatings can provide an additional line of defense against moisture ingress, which can lead to short circuits.

The scaffolding that supports solar panels should also be robust. If the panels are not installed correctly or securely, the movement might cause wear and tear, leading to wiring damage and connection failures over time. Instituting a quality assurance protocol to check for materials’ certification and warranty ensures that only the best components are utilized.

3. INSTALLATION TECHNIQUES AND BEST PRACTICES

Proper installation techniques are fundamental to minimizing risks associated with short circuits. The installation process requires skilled professionals who understand the intricacies of solar technologies and the potential vulnerabilities during setup. Incorrect wiring can lead to hazardous situations, including grounding issues and exposure of conductive materials.

One best practice involves ensuring that all wiring is adequately insulated and that connections are securely fastened. Loose or exposed wires are significant hazards that can easily lead to shorts. Additionally, employing protective conduits can provide an extra layer of security against physical damage and environmental factors.

Moreover, the positioning of solar panels must be strategic. If they are improperly oriented or too close to other metallic structures, this proximity could create a path for electrical faults to arise due to the conductive nature of metals. It is crucial to maintain a safe distance and ensure that there are no overlapping electrical pathways that can lead to shorts.

4. MAINTENANCE AND INSPECTIONS

Regular maintenance should be viewed as a non-negotiable aspect of solar systems operation. Even the most diligently installed solar power installations can suffer from wear and tear over time. Establishing a maintenance schedule aids in early detection of potential short circuit causes. Inspectors should assess the integrity of the wiring, the security of connections, and the condition of panels themselves.

Routine checks may include looking for signs of corrosion on connectors, which can develop due to weather exposure over time. Regular cleaning, especially in areas prone to dust accumulation, is also crucial, as dust can hinder performance and may trap moisture when it rains.

Creating a log of maintenance activities serves not just as a record but can help identify patterns that might indicate specific issues are becoming more frequent. For instance, if inspections uncover numerous instances of corrosion, it may indicate that either the materials selected for installation are inadequate or that the environment is harsher than previously assessed.

5. ENVIRONMENTAL FACTORS AND SOLUTIONS

Environmental conditions significantly impact the efficacy and safety of solar cells. Factors such as humidity, extreme weather, and temperature fluctuations can increase the likelihood of short circuits. In regions with high moisture, implementing moisture barriers and drainage systems can protect electrical components from excess water intrusion.

Moreover, during severe weather events, ensuring that solar panels are secure can prevent physical damage that leads to shorts. This might include using strong fasteners or installing panels at a sufficient angle to minimize wind load and snow accumulation.

Another approach involves employing monitoring systems that can alert operators to fluctuations in performance, signaling potential issues that could lead to shorts. Many modern solar systems come equipped with smart sensors capable of detecting abnormalities. Leveraging technology in monitoring can enable quicker detection and response to risks.

6. THE ROLE OF PROTECTIVE DEVICES

Protective devices are crucial in safeguarding solar power systems from surges and short circuits. Fuses and circuit breakers serve as primary defense mechanisms, automatically cutting off power in the event of an overload or fault condition. This ensures that damage that could lead to a short circuit is minimized.

Moreover, employing additional devices such as surge protectors can bolster resistance to unexpected power surges caused by outdoor phenomena, such as lightning strikes. These devices can act as the last line of defense, providing a buffer that absorbs excess energy.

Investing in advanced monitoring systems can further elevate protective measures. By using sensors integrated with automation, operators can preemptively address issues before they escalate. Timely data analytics can highlight trends or emerging issues, making it easier to act before a situation results in a short circuit or other failures.

FREQUENTLY ASKED QUESTIONS

WHAT ARE THE SIGNS OF A SHORT CIRCUIT IN SOLAR CELLS?

Several indicators may suggest a short circuit in solar cells. The most prominent sign is a noticeable drop in energy output, as the system can no longer function effectively. Technicians may also observe a burning smell or find physical damage in the wiring or panels. Another common symptom is the presence of flickering lights in systems powered directly by the solar setup, indicating interruptions in power flow.

Additionally, if circuit breakers frequently trip or fuses blow unexpectedly, those issues might correlate with short circuit conditions. In serious cases, physical inspection could reveal scorch marks on cables or connectors. Proactively inspecting the system can help alleviate risks associated with short circuits by addressing potential issues immediately upon detection.

HOW OFTEN SHOULD MAINTENANCE BE PERFORMED ON SOLAR PANELS?

Routine maintenance for solar panels is typically advised at least once or twice a year. However, the frequency of inspections may vary depending on environmental conditions, type of installation, and overall usage. For areas prone to heavy dust, rainfall, or snow accumulation, engaging in more frequent assessments may prove beneficial.

During maintenance checks, professionals should clean panels, ensuring they are free from obstructions that could affect performance. Furthermore, inspections should focus on checking the integrity of wiring, the physical safety of installations, and other components of the solar power system.

After extreme weather events, it may be prudent to conduct post-storm assessments to confirm that installations remain safe and operable. A diligent maintenance routine is key to ensuring longevity and reliability in solar energy systems.

WHAT TYPES OF PROTECTIVE MEASURES EXIST FOR SOLAR CELL SYSTEMS?

Various protective measures can minimize risks associated with solar cell systems. Fuses and circuit breakers are standard devices that automatically interrupt power in case of overloads or short circuits.

Surge protectors can prevent damage from power spikes, while moisture barriers can guard against water ingress in areas with high humidity levels. Additionally, employing high-quality conduit and weatherproofing materials allows systems to withstand environmental factors effectively.

Lastly, installing monitoring systems enables real-time diagnostics, allowing for quicker responses to any irregularities or performance drops. A combination of these protective measures can significantly enhance the safety and performance of solar energy systems.

Ensuring the integrity of solar cells and preventing short circuits is vital for maximizing efficiency in renewable energy production. By focusing on quality materials, proper installation, rigorous maintenance, and deploying protective measures, stakeholders can safeguard their solar investments against the risks posed by short circuits. Continuous education on optimal practices can empower solar energy users to make informed decisions that bolster the reliability and effectiveness of their systems. These practices not only contribute to better energy yield but can also ensure that the environmental benefits associated with solar technology are realized fully. As the importance of sustainable energy sources grows, so does the onus on individuals and organizations to maintain the safety and efficiency of their solar power systems. Consequently, prioritizing such measures will ultimately lead to more robust energy solutions that can withstand the test of time and environmental challenges.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-prevent-short-circuit-in-solar-cells/