Opening a solar dielectric tube requires specific methods to ensure efficiency and safety. 1. Proper preparation is essential, which includes gathering necessary tools and materials. 2. Identifying the tube’s specific design is crucial for determining the correct approach. 3. Following precise steps promotes effectiveness and reduces the risk of damaging the tube. 4. Safety precautions must be observed throughout the entire process to prevent accidents.

1. PREPARATION AND TOOLS NEEDED

Accomplishing the task of opening a solar dielectric tube necessitates meticulous preparation. This stage is pivotal, as it sets the groundwork for the entire process. First and foremost, it is essential to gather all of the necessary tools and materials that will assist in the procedure. Commonly required tools include protective eyewear, gloves, a precise cutting tool (such as a pipe cutter or a utility knife), and a pair of pliers. Having the right equipment on hand will not only contribute to a smoother operation but will also ensure safety throughout the endeavor.

In addition to tools, understanding the type of dielectric tube at hand is equally important. Solar dielectric tubes come in various types and sizes, which can significantly influence the method used to open them. Familiarizing oneself with the manufacturer’s guidelines and recommendations can lead to a more effective and damage-free opening process. By knowing the dimensions of the tube, one can choose an appropriate cutting tool, as well as anticipate the tube’s structural characteristics.

2. UNDERSTANDING SOLAR DIELECTRIC TUBES

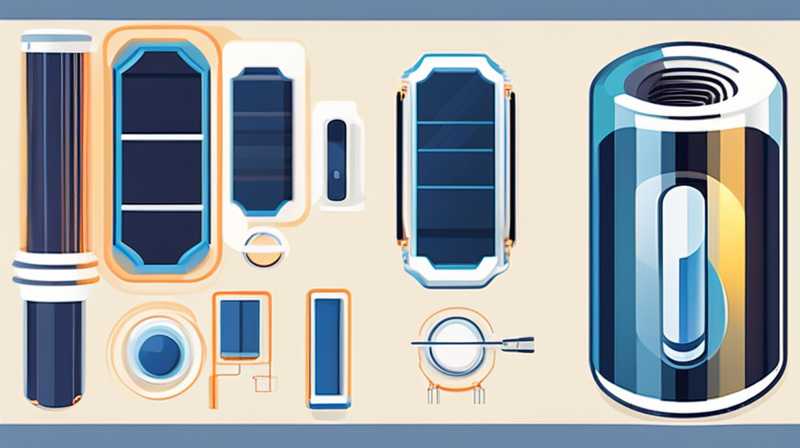

Solar dielectric tubes are specialized components often used in solar thermal systems. Their primary function is to transmit solar energy while minimizing heat loss. These tubes are constructed from materials that provide insulation and are resistant to high temperatures and environmental wear. To fully grasp the concept of opening these tubes, one must first understand their configuration and purpose.

Typically, dielectric tubes consist of a solid inner layer and an outer layer designed to protect against ultraviolet radiation and physical damage. The construction can vary, as some tubes are reinforced for additional strength. It is crucial to acknowledge this complexity, as understanding the layers involved will help in determining the right technique required to avoid compromising the structure while opening the tube.

3. SAFETY PRECAUTIONS

When engaging in any technical task, safety must always take precedence. In the case of disassembling a solar dielectric tube, specific precautions should be adhered to ensure that injuries do not occur. Wear appropriate personal protective equipment (PPE), including gloves and goggles, to minimize exposure to potential hazards related to cutting and handling materials.

In addition, ensure that the workspace is clean and free of any clutter or unnecessary items. Having a well-organized environment not only contributes to a more efficient workflow but also helps to limit the chances of accidents. Furthermore, working in a well-ventilated area is critical, particularly if the materials being manipulated emit fumes, although this is less common with dielectric materials.

4. STEP-BY-STEP PROCEDURE

Initiating the process of opening a solar dielectric tube involves following a meticulous and structured approach. Start by identifying the section of the tube to be opened. If there are any end caps or seals, these should first be removed carefully using the appropriate tool. Once the sealing elements are taken off, assess the tube’s structural integrity to determine the best cutting method.

Next, align the cutting tool along the predetermined cutting line. It is advisable to perform multiple light passes with the cutter to ensure a clean cut rather than attempting to slice through in one motion, which could lead to unwanted cracking or splintering of the material. Ease and control are paramount during this process to achieve an even cut without applying excessive force, which could potentially damage the tube.

5. FINALIZING THE OPENING

Upon completing the cutting procedure, inspect the opened edge of the tube for any rough edges or irregularities. It may be necessary to smooth out any sharp areas using a utility knife or sandpaper. Take your time during this phase to ensure that all edges are safe for handling, which is particularly essential if the tube will be reassembled or connected to other components of the solar thermal system.

Lastly, ensure that any removable components, such as adapters or fittings, seal correctly with the new configuration. This final verification step is crucial as it ensures that operational efficiency is not hindered, and that further maintenance requirements are minimized. Properly closing up any opened tubes will extend their lifespan and enhance performance.

SOLAR DIELECTRIC TUBES: FREQUENTLY ASKED QUESTIONS

WHAT MATERIALS ARE SOLAR DIELECTRIC TUBES MADE OF?

Solar dielectric tubes are predominantly constructed from specific polymers or specialized plastic compounds engineered to withstand high temperatures while minimizing thermal energy loss. These materials often possess strong insulating properties, making them ideal for capturing and transmitting solar energy efficiently. The outer layers are typically UV-resistant, preventing degradation over time. It is important to recognize that the quality of materials used directly affects the longevity and performance of solar thermal systems.

Some tubes may also incorporate glass reinforcement or coatings to enhance structural integrity. The decisions made by manufacturers regarding material selection are vital, as they influence factors such as heat retention, durability against environmental elements, and overall efficiency. Being aware of the materials used in solar dielectric tubes can inform the approach to both opening and maintaining them effectively.

HOW DOES ONE ENSURE A CLEAN CUT WHEN OPENING A SOLAR DIELECTRIC TUBE?

Achieving a clean cut when opening a solar dielectric tube is paramount to ensure proper functioning and sealing of connected components. First and foremost, using the correct cutting tool is essential. A pipe cutter is preferred, as it provides even pressure along the cutting line, helping achieve a uniform break without creating jagged edges.

Moreover, it’s advisable to take several light passes rather than attempting to cut through the material in one single motion. This gradual approach allows for better control and results in a neater cut. Post-cutting, one should smooth any sharp edges with a utility knife or sandpaper to prevent any issues during reassembly or use. Such diligence, particularly regarding the finishing touches, contributes significantly to the overall integrity of the solar thermal system.

ARE THERE ANY COMMON MISTAKES TO AVOID WHEN OPENING A SOLAR DIELECTRIC TUBE?

Several common pitfalls can arise during the process of opening solar dielectric tubes. One critical mistake involves applying excessive force while cutting. This can lead to cracking or splintering, which harms not only the integrity of the tube but can also pose hazards during handling.

Additionally, neglecting to wear protective equipment can result in severe injuries from sharp edges or mishaps with cutting tools. Lastly, failing to inspect the tube post-opening for defects or damage can lead to future problems, particularly in systems reliant on tight seals. Avoiding these mistakes ensures that the tube remains functional and prolongs the life of the entire solar system.

Opening a solar dielectric tube requires careful consideration and execution of multiple aspects to guarantee safety and effectiveness. All preparatory measures, including the tools and safety equipment, must be well-planned to facilitate a smooth process. Maintaining awareness of the complex nature of these tubes, including their construction and material characteristics, will aid users in approaching this task with a more informed perspective. Careful actions throughout each stage, from the initial cut to the final inspection, ensure not only the integrity of the solar thermal system but also the security of the person handling the tube. Moreover, awareness of common issues that may arise during the process helps in advancing individuals’ skill sets and enhances overall operational efficiency. Practicing diligence and adhering to a structured approach will result in successful openings of solar dielectric tubes and maintain the performance reliability crucial for solar energy systems. Therefore, an informed and methodical approach is imperative for achieving optimal results while ensuring safety and functionality.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-open-the-solar-dielectric-tube/