1. SOLAR SOLENOID VALVE MODIFICATION INVOLVES SEVERAL KEY STEPS TO ENSURE EFFICIENCY AND FUNCTIONALITY, 2. THE VALVE MUST BE SETUP WITH PROPER ELECTRICAL CONNECTIONS TO ENABLE CONTROL, 3. ADJUSTING THE VALVE TENSION CAN OPTIMIZE PERFORMANCE, AND 4. TESTING THE SYSTEM POST-MODIFICATION IS ESSENTIAL FOR SAFETY AND RELIABILITY.

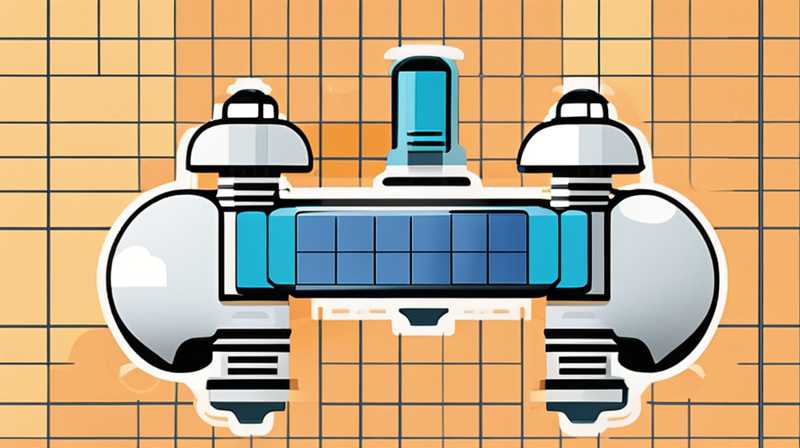

An in-depth exploration of the modifications applicable to a solar solenoid valve reveals critical steps that directly enhance its functionality within a solar energy system. A solenoid valve, integral to the regulation of fluid flow, operates under electrical power, rendering it essential for controlling various processes related to solar water heating applications. As applications diversify and system requirements evolve, there arises a compelling need to adapt these valves for enhanced performance.

1. UNDERSTANDING SOLENOID VALVES

The fundamental role of a solenoid valve within a solar energy system cannot be understated; it serves as a control device that allows or restricts fluid flow in response to electrical signals. Understanding the operations of solenoid valves necessitates a deeper comprehension of their components, including the coil, armature, and valve body. The electromagnetic coil energizes to generate a magnetic field that moves the armature, consequently opening or closing the valve.

To explore the operational characteristics of solenoid valves, one must consider different types available on the market, such as direct-acting and pilot-operated varieties. Direct-acting valves respond directly to applied voltage, while pilot-operated valves need an additional source of pressure to function properly. Identifying the correct type for your specific application is paramount, as this choice can significantly affect the overall efficiency of the solar energy system.

2. PREPARING FOR MODIFICATION

Having identified the solenoid valve applicable to the solar system, the subsequent phase entails preparation for the intended modifications. Adopting appropriate safety measures is vital to avoid accidents during the process. Begin by disconnecting the power supply to the solenoid valve and ensuring that all pressures within the system have been alleviated. This precautionary step is essential since residual pressure could lead to harmful explosions or injuries during the modification process.

Documentation also plays a critical role in the preparatory phase. A detailed schematic of the existing electrical and fluid connections must be created, Serves as a reference during and after the modification. The design should also include information about the solenoid valve’s specifications, including voltage and current ratings, which will guide any electrical modifications required. Thorough preparation helps to streamline adjustments and ensures a smooth transition throughout the modification process.

3. MODIFYING ELECTRICAL CONNECTIONS

Once the preparatory phase is complete, attention may shift towards modifying the electrical connections associated with the solenoid valve. The precise control of fluid flow within a solar heating system is achieved through finely tuned electrical connections, establishing how the solenoid valve will interact with other components.

The first adjustment may include replacing existing wiring to accommodate higher voltage or amperage ratings. This change may necessitate the use of heavier gauge wires, which can withstand prolonged electrical loads without overheating. Ensuring that all connections are watertight is crucial while employing heat-shrink tubing or other sealing solutions. Proper insulation around connections contributes to the longevity and reliability of the electrical system.

Additionally, integrating a controller with relay outputs allows for better modulation of the valve based on real-time feedback from temperature sensors or photovoltaic inputs. Employing such control mechanisms enhances the valve’s responsiveness to the dynamic requirements of the solar system, optimizing the overall efficiency of the setup.

4. ADJUSTING VALVE TENSION

Beyond electrical modifications, the mechanical aspects of the valve must not be neglected. A solenoid valve’s operational efficiency often hinges on the tension settings of its internals. Over time, factors such as temperature fluctuations and repeated cycles can alter the tension within the system, leading to suboptimal performance.

To begin the adjustment process, the valve cover must be removed carefully. This step reveals the internal spring mechanism correlating to the valve’s operation. By measuring the existing tension and comparing it to the manufacturer’s specifications, adjustments can be made accordingly. Using tools such as a torque wrench will ensure precise application, allowing for the proper establishment of spring tension.

Ensuring that the valve adequately seals under different pressure scenarios is significant in preventing leaks. Over-tightening or under-tightening can lead to problems, so approaching adjustments methodically promotes long-term functionality. The characteristics of the application, such as temperature ranges and type of fluids flowing through the system, also dictate the necessary tension adjustments.

5. TESTING AND OPTIMIZATION

After making the necessary modifications to the solar solenoid valve, thorough testing is critical to validate functionality and safety. Following all adjustment protocols, carefully reconnect the electrical supply and check for leaks in the valve and associated piping systems. Performing a comprehensive system check using diagnostic tools will illuminate any potential issues that may arise.

Monitoring the valve’s response to control signals provides insight into performance under different scenarios. Continuous feedback helps identify any unexplained irregularities in its operation, enabling prompt corrective measures. By incorporating data logging techniques and trend analysis, predictions regarding valve behavior can be made, enhancing the overall control strategy.

FREQUENTLY ASKED QUESTIONS

WHAT COMMON PROBLEMS CAN OCCUR IN SOLENOID VALVES?

Solenoid valves may face several issues affecting their operational efficiency. The most prevalent problem includes leakage, which often arises from worn-out seals or improper adjustments during modifications. Inadequate electrical supply can also hinder the solenoid from actuating properly, leading to intermittent operation. Additional issues may involve blockages from sediment or debris, which restricts fluid flow, and resultant wear on internal components due to cycling stress. Regular maintenance checks can alleviate many of these concerns through early detection and correction.

HOW OFTEN SHOULD SOLENOID VALVES BE SERVICED?

The servicing frequency for solenoid valves directly correlates with the specific operating conditions of the system in which they are installed. In high-use scenarios where the valve experiences repeated cycling, quarterly inspections are advisable, allowing for timely identification of wear and tear. Conversely, in less demanding environments, semi-annual evaluations may suffice. Regardless of use, a yearly systematic inspection is recommended to ensure that all components function without hindrance and to enable the upgrading of any outdated technology. Regular service can enhance the lifespan of the solenoid valve, ensuring sustained efficiency and reliability.

CAN SOLENOID VALVES BE USED FOR BOTH HOT AND COLD FLUIDS?

Indeed, solenoid valves exhibit versatility in accommodating both hot and cold fluids within various applications. However, choosing the appropriate valve type and materials is essential for optimal performance and safety. Geared towards applications involving higher temperatures, valves must be constructed from heat-resistant materials, while cold applications may only require standard valve constructions. Additionally, operators must be cognizant of the fluid’s viscosity and potential for coagulation at lower temperatures, as this can impact the valve’s function. Careful analysis of system specifications aids in selecting valves that operate efficiently under variable conditions.

MODIFICATION OF SOLAR SOLENOID VALVES PLAYS A SIGNIFICANT ROLE IN ENSURING EFFICIENT OPERATIONS WITHIN SOLAR ENERGY SYSTEMS. THOROUGH UNDERSTANDING OF VALVE MECHANICS, PREPARATION PROCEDURES, ELECTRICAL CONNECTIONS, AND TENSION ADJUSTMENTS GENERATES A SOLID FOUNDATION FOR SUCCESSFUL MODIFICATION. CONTINUAL TESTING AND MAINTENANCE POST-MODIFICATION HELP TO IDENTIFY POTENTIAL ISSUES, THUS PROMOTING LONG-LASTING RELIABILITY. BY FOCUSING ON CRUCIAL ASPECTS OF SOLENOID VALVE MODIFICATIONS AND REGULAR SERVICING, OPERATORS CAN OPTIMIZE SOLAR SYSTEM FUNCTIONING TO MEET DEMANDS IN AN EVOLVING ENVIRONMENT. THUS, INCREASED PERFORMANCE LEADS TO GREATER OVERALL EFFICIENCY AND INTEGRITY WITHIN SOLAR ENERGY APPLICATIONS, FOSTERING SUSTAINABILITY WITHIN ENERGY SYSTEMS.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-modify-the-solar-solenoid-valve/