To fabricate solar energy mechanical equipment, one must understand several key elements: 1. Technical knowledge is essential for design and construction, 2. Selecting appropriate materials ensures efficiency and durability, 3. Understanding energy conversion processes maximizes performance, 4. Proper installation and maintenance prolong the lifespan of the equipment. The first point requires a detailed knowledge of mechanical and electrical engineering principles, as well as specific knowledge pertaining to solar technology. This involves not only the fundamental concepts of how solar panels work but also a grasp of mechanics to create equipment that can efficiently harness and transform solar energy into usable power.

1. UNDERSTANDING SOLAR ENERGY

Solar energy refers to the radiant light and heat from the sun that can be harnessed using various technologies, primarily photovoltaic cells and solar thermal systems. Solar panels are the most well-known technology in this context. They convert sunlight directly into electricity, utilizing semiconductor materials to facilitate this process. Sunlight excites electrons in the semiconductor, generating an electric current. The efficiency of solar panels is heavily influenced by various factors, including material composition, temperature, and the angle at which sunlight hits the panels. The understanding of these parameters is essential when designing mechanical equipment that incorporates solar technology.

Moreover, beyond the basic function of converting solar energy into electricity, the significance of solar thermal collectors cannot be overlooked. These systems capture sunlight to produce heat, which can then be used for residential heating, hot water production, or even in industrial processes. Understanding the various solar collection methods allows for the creation of innovative mechanical equipment that can leverage both electrical and thermal energy. Therefore, a comprehensive grasp of both photovoltaic and thermal technologies is vital for anyone involved in the design and fabrication of solar energy mechanical equipment.

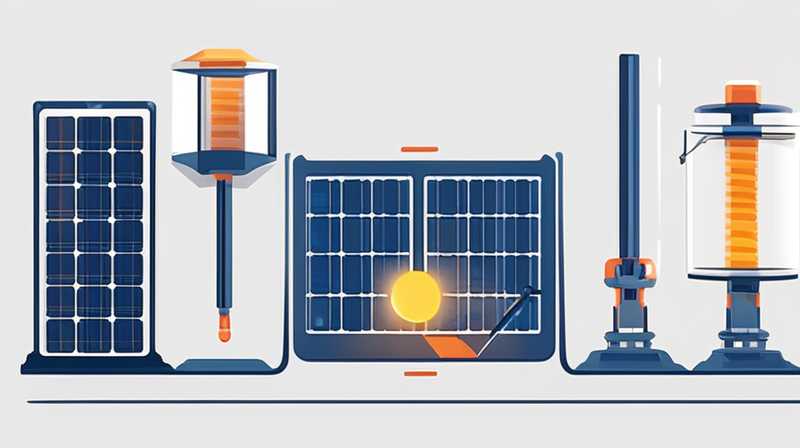

2. COMPONENTS OF SOLAR ENERGY MECHANICAL EQUIPMENT

The construction of solar energy mechanical equipment typically involves several key components, each playing a critical role in overall functionality. Starting with the solar panel itself, the selection of high-efficiency panels can significantly improve energy capture and conversion rates. It’s essential to consider factors such as cell efficiency, warranty, and degradation rates when choosing solar panels, as these attributes directly impact long-term performance and overall return on investment.

In addition to the panels, inverters are another critical component. They convert the direct current (DC) produced by solar panels into alternating current (AC), which can then be used to power home appliances or fed back into the grid. Choosing a quality inverter is critical, as the efficiency of this component can affect the overall energy output of the solar energy mechanical equipment. Furthermore, there are different types of inverters, including string inverters, microinverters, and power optimizers, each suitable for specific applications based on factors such as shading, system size, and installation environment.

3. MECHANICAL DESIGN CONSIDERATIONS

The design of solar energy mechanical equipment must consider various aspects to ensure functionality and efficiency. Structural integrity is paramount; the equipment must withstand environmental factors such as wind, rain, and snow. Therefore, materials chosen for frames and mountings must possess adequate strength and durability. Aluminum and galvanized steel are popular choices due to their resistance to corrosion and high strength-to-weight ratios.

Moreover, it’s crucial to design for the angle and orientation of solar panels. Optimal tilt angles can significantly impact energy capture, allowing equipment to maximize solar exposure throughout the year. The design must permit adjustments to angles to facilitate optimal performance across different seasons. Adequate consideration of shading caused by nearby structures, trees, or even the equipment itself is essential as well, as this can dramatically reduce energy output.

4. INSTALLATION AND MAINTENANCE

The installation process of solar energy mechanical equipment is as critical as its design. Proper installation determines not only the immediate performance but also the longevity of the equipment. It involves precise positioning of solar panels, careful routing of electrical cables, and secure mounting to withstand external weather conditions. Collaborating with experienced contractors or engaging certified installers can minimize potential errors, ensuring adherence to best practices and local codes, which can be intricate in different regions.

Maintenance is also a significant aspect that cannot be overlooked. Regular inspections and cleaning are essential to ensure consistent performance. Panels can accumulate dirt, bird droppings, and debris, all of which can impede their ability to absorb sunlight. Implementing routine maintenance schedules will yield better energy output and prolong the life of the equipment. Familiarity with troubleshooting common issues such as inverter failures, disconnects, and performance degradation is crucial for anyone involved in the operational aspects of solar energy mechanical equipment.

5. ECONOMICS OF SOLAR ENERGY

Investing in solar energy mechanical equipment can present both opportunities and challenges from an economic perspective. The initial capital outlay can be substantial, which includes costs for solar panels, inverters, installation, and additional equipment such as batteries for energy storage. Nevertheless, the long-term savings on energy bills can offset these initial expenses, especially in regions with high electricity rates.

Additionally, the availability of government incentives, rebates, and tax credits can significantly alleviate upfront costs. Understanding the local and national policy landscape is essential for potential investors. Advantages offered by various programs can substantially reduce the effective pricing of solar installations, enhancing overall return on investment. Moreover, as technology continues to advance, costs associated with solar energy systems are declining, which further enhances their economic viability.

6. ADVANTAGES AND DISADVANTAGES

Solar energy mechanical equipment comes with its own set of advantages and disadvantages. On the positive side, solar energy is renewable and contributes to reducing carbon footprints, making it an environmentally friendly option compared to fossil fuels. Furthermore, once the equipment is installed, operational costs are relatively low, since sunlight is free.

However, there are also limitations to consider. Solar energy production is intermittent and depends on weather conditions and time of day, which can impact energy availability. Energy storage solutions such as batteries can help mitigate this issue, but they come with additional costs and require careful design considerations. Ensuring a balance between energy production, storage, and consumption patterns is necessary to optimize performance.

7. FUTURE OF SOLAR ENERGY MECHANICAL EQUIPMENT

Looking ahead, the future of solar energy mechanical equipment appears promising. Technological advancements are continually evolving, paving the way for more efficient solar panels, smarter energy management systems, and innovative integration with other renewable sources. The transition to a more sustainable energy paradigm emphasizes the role of solar energy in meeting global energy demands.

One noteworthy trend is the increasing adoption of decentralized energy systems that empower individuals and communities to generate and manage their energy production. This shift signifies a move toward greater energy independence and resilience, as homeowners and businesses invest in their own solar energy mechanical systems. Additionally, research into materials such as perovskites may further revolutionize the efficiency and applications of solar technology, making it more accessible and widespread.

QUESTIONS AND ANSWERS

WHAT MATERIALS ARE REQUIRED FOR MANUFACTURING SOLAR ENERGY MECHANICAL EQUIPMENT?

When constructing solar energy mechanical equipment, several materials are necessary to ensure efficiency and longevity. The primary components include photovoltaic panels, inverters, mounting hardware, and sometimes energy storage systems such as batteries. Solar panels are generally made from crystalline silicon, a material known for its efficiency in converting sunlight to electricity, but alternatives like thin-film technologies also exist.

Inverters, whether string inverters or microinverters, typically consist of electronic components that convert the direct current (DC) from solar panels into alternating current (AC) that can be used in homes or returned to the grid. Mounting systems, crucial for securely holding the panels in place, are commonly constructed from aluminum or steel to provide both durability and corrosion resistance. Additionally, wiring and electrical connectors need to be of high-grade material to support efficient energy transmission. Regular maintenance will require cleaning solutions and tools designed specifically for solar applications to ensure that equipment remains operational and efficient.

HOW DOES SOLAR ENERGY CONVERSION WORK?

The conversion of solar energy into usable power involves several processes, primarily utilizing photovoltaic cells or solar thermal collectors. In photovoltaic systems, solar panels composed of semiconductor materials like silicon absorb sunlight and generate electric currents. This occurs when photons from sunlight excite electrons in the semiconductor, creating a flow of electricity. This direct current (DC) generated is then transformed into alternating current (AC) through an inverter, making it suitable for home appliances or grid integration.

On the other hand, solar thermal systems operate on a different principle. These systems are designed to capture sunlight and convert it to heat rather than electricity. Through the use of fluid-filled collectors, water or another heat-transfer fluid is heated by direct sunlight. This hot fluid can be used for heating spaces, providing hot water, or even generating steam to drive turbines for electricity production. Each method of energy conversion has its advantages and specific applications, emphasizing the versatility of solar technology in harnessing energy from the sun.

WHAT FACTORS IMPACT THE EFFICIENCY OF SOLAR ENERGY MECHANICAL EQUIPMENT?

Numerous factors influence the efficiency of solar energy mechanical equipment, starting with the characteristics of solar panels themselves. Materials, technology type, and design can significantly determine how effectively sunlight is converted into usable energy. For instance, monocrystalline silicon panels tend to have higher efficiency ratings compared to polycrystalline options. Seasonal variations such as weather conditions and sunlight availability also play a crucial role; cloudy days or excessive shading from nearby structures can diminish energy production.

Furthermore, the angle at which solar panels are installed is vital. Optimal positioning allows for maximum sunlight exposure throughout the day and across different seasons. Other factors include the performance of inverters and the type of electrical wiring used, as inefficiencies in these components can lead to energy losses. Regular maintenance and cleaning of panels are also essential, as dirt and grime can obscure sunlight and reduce energy capture, thereby affecting overall system efficiency. Properly addressing these factors can result in a substantial improvement in solar energy mechanical equipment performance.

Solar energy mechanical equipment plays a crucial role in harnessing the sun’s power for sustainable energy production. The process of designing, constructing, and maintaining this equipment consists of multifaceted considerations involving technical, economic, and structural disciplines. With a growing emphasis on renewable energy sources, investments in solar technology not only contribute to environmental preservation, they also create opportunities for energy independence and long-term savings for consumers. The shift towards solar energy systems represents not only a commitment to sustainability but also a strategic move toward energy security in an era increasingly focused on ecological conservation. Innovations in materials, design, and installation practices continue to enhance the capabilities and efficiency of solar energy systems. Each component, from the choice of materials to the integration of smart technologies, collectively represents a movement towards a more robust and sustainable energy future. Adapting to the continuous advancements in solar technology ensures that stakeholders remain at the forefront of this transformation, capitalizing on the myriad benefits presented by solar energy. In summary, the ongoing journey in creating effective solar energy mechanical equipment is not just a scientific endeavor, but a societal shift towards a greener and more sustainable world.**

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-make-solar-energy-mechanical-equipment/