To create a solar circulation tube, follow these essential steps: 1. Select suitable materials, including a transparent tube for efficient light capture, insulation to minimize heat loss, and connectors for water circulation. 2. Construct the system by assembling the tube in a manner that allows for solar heat absorption, ensuring proper positioning towards the sun. 3. Fill the tube with a heat-transfer fluid, such as water or antifreeze, to facilitate heat exchange. 4. Integrate the circulation system, incorporating a pump to circulate the fluid, and connect it to the desired application, such as a solar water heater. This method effectively harnesses solar energy for heating purposes, promoting renewable energy use and sustainability in domestic and commercial settings. The detailed explanation of the operation, efficiency considerations, and installation tips will be elaborated in the subsequent sections.

1. MATERIAL SELECTION AND PREPARATION

The foundational aspect of constructing a solar circulation tube lies in the selection of appropriate materials. Materials must be high in thermal efficiency. The use of a clear, high-quality plastic or glass tube is critical for allowing sunlight to penetrate effectively. Specific materials such as polycarbonate or acrylic are favored for their durability and excellent light transmittance. The insulation material should ideally be foam or fiberglass, effectively reducing heat loss via convection and conduction.

Another crucial component in this phase is the fluid that will operate within the tube. Liquid choice significantly influences heat transfer efficiency. Water is a common option due to its accessible nature and high specific heat capacity, but the inclusion of antifreeze is advisable in colder climates to prevent freezing and ensure year-round functionality. When gathering materials, it’s vital to consider additional elements like connectors and pumps, which will later facilitate fluid movement through the system.

Proper preparation of these materials is essential before construction begins. Ensure all parts are clean and free from contaminants to maintain optimal performance levels. Additionally, familiarize yourself with the specific characteristics of each material to make the assembly process more efficient. Thorough preparation sets a strong foundation for the entire project.

2. SYSTEM ASSEMBLY AND DESIGN

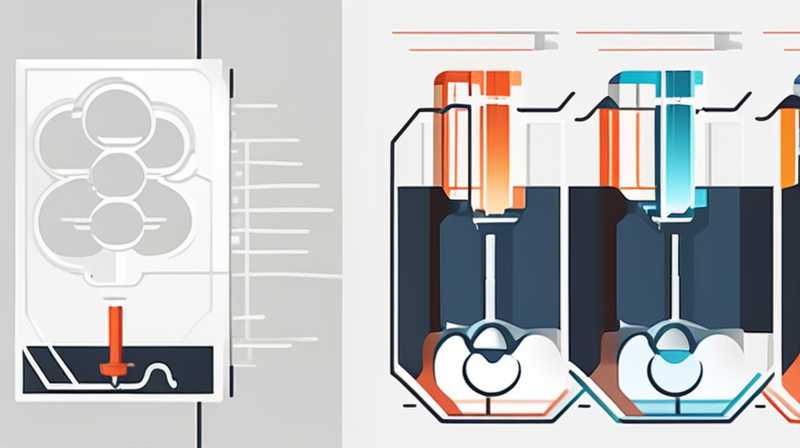

The assembly of the solar circulation tube system requires precise engineering to maximize solar heat absorption. Positioning of the tube is one of the most critical aspects in this design phase. The tube should be oriented towards the sun for the majority of the day, ideally at an angle that corresponds closely to the latitude of the installation site. This positioning enhances sunlight exposure, subsequently increasing energy efficiency.

In constructing the tube, ensure that all connections are airtight and secure to prevent leaks. Utilizing appropriate adhesives and sealants will extend the lifespan of the assembly. It is advisable to create a sealed environment within the tube to avoid moisture accumulation, which can corrode materials and reduce efficiency. Furthermore, ensure that the reflective surfaces, if integrated, are clean and positioned to enhance light absorption on the liquid inside the tube.

Attention must also be directed towards creating viable inlet and outlet points for the heat-transfer fluid. The circulation system should be designed to minimize resistance and optimize flow. Consider the placement of the pump; it should be situated to facilitate the most efficient circulation pattern. Drawing up a diagram during this phase can help visualize the system’s layout, ensuring that all components work harmoniously to achieve the desired heating outcome.

3. FILLING AND MAINTAINING THE SYSTEM

Once the solar tube has been assembled and securely positioned, the next phase involves filling the tube with the chosen heat-transfer fluid. Proper filling techniques are essential to prevent air pockets, which can greatly reduce efficiency. Introducing the fluid should be done slowly, allowing it to displace air. If using water, consider adding an antifreeze solution to ensure functionality in changing temperatures.

Routine maintenance is crucial for ensuring ongoing operational efficiency. Regular checks on fluid levels, connector conditions, and overall system integrity cannot be overstated. Replacement of the fluid may be necessary over time, especially if the system exhibits signs of contamination, which can occur due to exposure to environmental elements. Implementing a seasonal maintenance routine can improve longevity and performance.

Monitor the system for signs of leaks or blockages, which can significantly affect energy efficiency. Identifying issues early on can prevent costly repairs or replacements later. Additionally, the exterior surfaces should be kept clean to maximize solar absorption. Neglecting these aspects can lead to diminished returns on investment, as an efficient system needs optimal functioning conditions to truly harness solar energy effectively.

4. INTEGRATING THE CIRCULATION SYSTEM

Integration of the circulation system plays a pivotal role in the overall efficiency of the solar circulation tube. Employing a high-efficiency pump can lead to optimal circulation rates, enhancing thermal transfer. The pump must be properly sized; too small will result in inadequate fluid movement, while too large may waste energy and create unnecessary wear.

The connection of the pump to the inlet and outlet must ensure smooth transitions, minimizing the risk of back pressure, which can impede fluid flow. Utilizing flexible piping for connections can facilitate movement and adjustments while accommodating thermal expansion. Ensuring that the piping is insulated can prevent heat loss during transit from the solar tube to the intended application.

Monitoring the performance of the pump and circulation system is essential. Implementing monitoring tools can provide real-time data on performance metrics, allowing for quick adjustments and troubleshooting when needed. Understanding how the system responds under varying sunlight conditions and fluid temperatures can assist in optimizing the operation further. Ensuring the entire system is balanced and functioning well will ultimately lead to better thermal efficiency and longevity.

5. APPLICATION AND USAGE OF SOLAR CIRCULATION TUBES

The application of solar circulation tubes is incredibly versatile and spans various industries and residential sectors. Solar heating systems for domestic water use are among the most prominent applications. Homeowners utilize these systems to heat water for showers, dishwashing, and laundry, significantly reducing energy costs and reliance on fossil fuels.

Beyond domestic usage, solar circulation tubes can be applied in larger scale installations such as swimming pools. By integrating solar heating systems with pool water circulation, owners can extend the swimming season without the high costs associated with traditional heating methods. Many municipal pools and private facilities have adopted this technology to improve sustainability while reducing operational costs.

Commercial applications include agricultural uses, where heated water can support processes such as greenhouse heating or aquaculture. These systems can enhance productivity and efficiency in industries heavily reliant on temperature control. Industries are increasingly acknowledging the environmental benefits and cost savings associated with implementing solar technologies, thus contributing to a more sustainable future.

FREQUENTLY ASKED QUESTIONS

WHAT ARE THE BENEFITS OF USING A SOLAR CIRCULATION TUBE SYSTEM?

Utilizing a solar circulation tube system offers multiple advantages, particularly in the realm of energy efficiency and sustainability. Firstly, it significantly reduces reliance on conventional energy sources, such as electricity and gas, leading to lower utility bills and a reduced carbon footprint. This is particularly beneficial for homeowners and businesses looking for renewable energy alternatives. Secondly, solar circulation tubes require minimal maintenance once installed, providing a reliable source of hot water and thermal energy with little ongoing effort.

Additionally, installation can often be carried out with a relatively straightforward process, making solar technology accessible to a broader audience. The adaptability of solar circulation tubes allows for application in various settings, from residential to commercial use, further enhancing their appeal. Moreover, with advances in technology, the efficiency of these systems continues to improve, making them an even more attractive option for those seeking to harness solar energy.

HOW DOES THE MAINTENANCE OF A SOLAR CIRCULATION TUBE SYSTEM WORK?

Maintenance of a solar circulation tube system is generally uncomplicated but critical for ensuring optimal efficiency and durability. Regular inspection is crucial, particularly to check fluid levels and examine connections for leaks or signs of wear. This can typically be done annually, though more frequent checks are advisable in extreme weather conditions. Checking the quality of the heat-transfer fluid is also essential; contaminated or degraded fluids can lead to significant losses in efficiency.

Additionally, ensuring that the external surfaces of the tube are clear of debris and dirt is vital. Clean glass or plastic ensures maximum solar transmittance, enhancing the heating capability of the system. In areas with significant temperature fluctuations, adjusting the antifreeze concentration within the fluid may be necessary. If these basic maintenance tasks are adhered to, systems can operate efficiently for many years, providing substantial energy savings and improving overall functionality.

CAN SOLAR CIRCULATION TUBES BE USED IN COLD CLIMATES?

Yes, solar circulation tubes can indeed be utilized in cold climates. However, considerations for freezing temperatures must be made to protect the system’s integrity and efficiency. Employing heat-transfer fluids like antifreeze becomes essential, especially in regions where temperatures can plummet. Antifreeze solutions ensure that the fluid does not freeze within the tube, maintaining continued flow and heating capacity throughout winter months.

Moreover, addressing insulation to prevent heat loss is paramount. Properly insulating all components of the system will help retain thermal energy even on cooler days. Tilt angle adjustments can also enhance solar absorption during late fall and winter. Although cold temperatures present certain challenges, well-planned design and efficient materials can lead to successful operation and heating capability throughout the off-seasons, thus ensuring year-round functionality.

A STRONG FOUNDATION FOR SUSTAINABILTY AND EFFICIENCY

In the journey of creating a solar circulation tube, meticulous attention to detail throughout every stage is imperative. The selection of the right materials serves as a vital starting point for effective construction. From the initial assembly and positioning to the integration of the circulation system, every decision plays a crucial role in the overall system’s effectiveness. By understanding how to maintain and operate the system properly, individuals and businesses can fully leverage the benefits of solar energy.

Adopting solar technology reflects a commitment to sustainable practices and embraces the growing shift towards renewable energy sources. Such systems not only offer cost savings on energy expenditures but also contribute positively to environmental efforts by reducing dependence on fossil fuels. As innovation continues to evolve in solar technology, the promise of enhanced efficiency and broadened applications remains strong, making solar circulation tubes a valuable investment for the future.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-make-solar-circulation-tube/