To create solar cells, one must follow a series of steps involving material selection, fabrication techniques, and assembly processes. 1. Utilize silicon or other photovoltaic materials, 2. Implement doping to create p-n junctions, 3. Apply anti-reflective coatings to maximize light absorption, 4. Construct protective layers for durability, 5. Integrate electrical connections to harness generated power. Each point plays a vital role in ensuring that solar cells effectively convert sunlight into electricity.

Among the significant aspects, the method of doping silicon (the process of adding impurities to silicon to enhance its electrical properties) is particularly crucial. The creation of p-n junctions is fundamental, as it defines how solar cells operate. When light strikes these junctions, it generates electron-hole pairs that lead to an electric current. The quality of this step directly impacts the overall efficiency of the solar cell and its capacity to function under varying conditions.

1. MATERIAL SELECTION

Choosing the appropriate materials is paramount in the creation of solar cells. Silicon is the most common substance used due to its abundance and desirable electronic properties. There are different forms of silicon, including monocrystalline, polycrystalline, and amorphous, each offering unique advantages and disadvantages. Notably, monocrystalline silicon provides the highest efficiency rates but is often more expensive to produce. Conversely, polycrystalline silicon tends to be less costly while delivering lower efficiency.

Beyond silicon, there are alternative photovoltaic materials, such as cadmium telluride, gallium arsenide, and organic compounds. These materials often compete with silicon-based cells in specific applications due to their varied efficiency, cost, and environmental impact. Exploring these alternatives is essential as it enables innovation in solar technology. For instance, gallium arsenide cells are known to be highly efficient but are costly to manufacture, making them suitable for specialized applications such as space technology.

The selection process must also consider the environmental impact of the materials. Sustainability plays a critical role in the future of solar energy. With emerging technologies, biodegradable solar cells and materials with lower carbon footprints are becoming increasingly significant. This focus on eco-friendliness not only addresses environmental concerns but also appeals to consumers who prioritize green technology.

2. DOPING AND P-N JUNCTION CREATION

Once the materials have been selected, the next vital step is doping silicon to create p-n junctions. Doping is a sophisticated technique that modifies the electrical properties of silicon, transforming it into a semiconductor. Typically, materials like phosphorus and boron are used for this purpose.

When silicon is doped with phosphorus, it gains extra electrons, becoming an n-type semiconductor. Conversely, doping with boron creates p-type silicon, characterized by an abundance of holes (the absence of electrons). The interface of these two types creates a p-n junction, where electric fields develop due to the movement of electrons and holes.

The significance of this junction cannot be overstated, as it enables the photovoltaic effect – fundamental to solar cell function. Upon exposure to sunlight, the junction allows for the separation of electron-hole pairs, leading to an electric current. Proper control of doping levels is essential because any imbalance can severely affect the efficiency of the solar cell.

Moreover, advancements in doping methodologies are being explored to enhance performance. Techniques such as ion implantation and diffusion provide precision in creating the desired doping profiles, thus optimizing the p-n junction characteristics. Innovations in this area contribute to improvements in solar cell efficiency, prolonging their lifespan and enhancing overall performance in real-world applications.

3. ANTI-REFLECTIVE COATINGS

After forming p-n junctions, the next critical component is the application of anti-reflective coatings. Sunlight reflection is an inherent obstacle to maximizing power generation; thus, thin films of materials such as silicon nitride or titanium dioxide are utilized to minimize this effect. These coatings effectively increase light absorption by allowing more photons to pass through to the active layers.

The coating plays a significant role in enhancing the efficiency of solar cells. Typically, about 30% of sunlight is reflected off the surface of silicon solar cells without an anti-reflective coating. The application of these films can reduce reflectivity to less than 5%, significantly improving the capture of available solar energy.

Moreover, advancements in the composition and application methods of these coatings are being actively researched. Techniques like layered coatings, which utilize multiple materials, can be fine-tuned to achieve specific wavelength absorption properties. As a result, smarter designs are emerging that can adapt to different light conditions, whether bright sunlight or cloudy scenarios, further enhancing the operational versatility of solar cells.

This aspect proves vital as renewable energy systems become ubiquitous in diverse environments. By improving light absorption, solar cells maximize their energy output, contributing to the overall efficacy and viability of solar technology as a primary energy source.

4. PROTECTIVE LAYERS AND ASSEMBLY

To provide durability and reliability, protective layers are applied over the solar cells. These layers safeguard against environmental factors such as moisture, dust, and mechanical impacts. Common materials for protective layers include tempered glass and polymer films, both known for their resilience and transparency.

The role of tempered glass is critical because it allows sunlight to penetrate while offering substantial protection from external damage. Its strength helps withstand hail and other physical impacts, ensuring the long-term viability of the cells beneath. Additionally, polymer films often provide UV protection, extending the lifespan of solar cells by minimizing degradation.

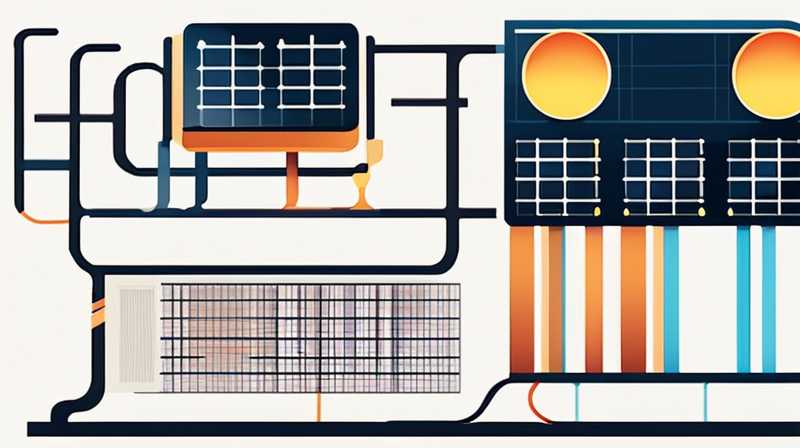

Assembly of solar cells into modules represents the culmination of the manufacturing process. Individual cells are interconnected to form panels, allowing for scalability in energy production. This assembly must be conducted with precision to ensure optimal connection and minimal loss of generated power.

The innovative design of solar modules also encompasses the arrangement of cells within the panel. Techniques such as bypass diodes are implemented to mitigate the effects of shading, which can significantly reduce output. These diodes allow current to bypass shaded cells, ensuring that the entire panel continues to operate efficiently.

Furthermore, the ongoing advancements in solar technology are paving the way for new assembly techniques that improve both efficiency and cost-effectiveness. Research into integrated solar technologies seeks to embed solar cells within building materials, creating a seamless interaction between architecture and energy generation. Such innovations represent a paradigm shift in how energy is harnessed and utilized, demonstrating the potential for integrating solar technology into everyday life.

5. TESTING AND QUALITY CONTROL

The manufacture of solar cells cannot overlook comprehensive testing and quality control procedures. These protocols are essential for ensuring that the cells meet stringent performance standards before they reach the market. Various methods, including electroluminescence and infrared thermography, are utilized to identify defects and validate efficiency.

Electroluminescence testing involves passing an electric current through the solar cells to visualize any defects, such as cracks or shunts. This method offers immediate feedback on cell quality, allowing manufacturers to address issues without delays. In contrast, infrared thermography detects hotspots in the solar cell array, indicating inefficiencies that could lead to power loss over time.

Ensuring high-quality output also involves rigorous performance testing under various conditions. This not only verifies efficiency levels but also assesses how the cells perform in real-world scenarios, such as varying temperatures and light intensities. Such comprehensive testing is vital for building consumer confidence and ensuring long-term reliability.

Quality control processes are integral to the solar cell manufacturing industry, contributing significantly to the perception of solar technology as a viable and sustainable energy source. As the solar market expands, the demand for rigorous quality assurance will continue to grow, prompting ongoing enhancements in both manufacturing and testing methodologies.

SOLAR CELLS FAQs

WHAT ARE SOLAR CELLS MADE OF?

Solar cells are primarily constructed from semiconductor materials, most notably silicon. Silicon can be found in two key forms: monocrystalline and polycrystalline, each with unique efficiency levels and costs. Monocrystalline cells are made from single crystal structures, providing higher efficiency and occupying less surface area, although they tend to be more expensive. Polycrystalline cells, formed from multiple crystal fragments, are typically easier and more economical to produce, resulting in slightly lower efficiency rates.

Beyond silicon, other materials also serve as alternatives. For instance, cadmium telluride is commonly used in thin-film solar cells for cost advantages and flexibility, making it favorable for large-scale projects. Gallium arsenide, while more costly, offers exceptional efficiency levels, making it useful in specialized applications like space technology.

Furthermore, ongoing advancements in research have led to organic photovoltaic materials, which offer flexibility and are potentially less harmful to the environment. These materials provide exciting possibilities for the future of solar technology. Overall, the base composition of solar cells is influenced by various factors, including efficacy, cost, and environmental considerations.

HOW DO SOLAR CELLS WORK?

Solar cells function on the principle of the photovoltaic effect, which converts sunlight directly into electricity. The process begins when sunlight hits the semiconductor material within the solar cell, exciting electrons and initiating a flow of energy. This occurs primarily at the p-n junction, a critical component formed through the doping of silicon.

Upon exposure to sunlight, photon energy is absorbed by the electrons in the semiconductor. When enough energy is provided, these electrons gain sufficient momentum to escape from their atomic bonds, creating electron-hole pairs. The electric field established at the p-n junction drives these free electrons towards the external circuit, while holes move in the opposite direction, creating a flow of electric current.

This process continues as long as sunlight is available. The generated current can then be harnessed for various applications, such as powering homes, businesses, or feeding into the grid. It is important to note that the efficiency of solar cells varies based on material types, the quality of the doping process, and the effectiveness of light absorption techniques. As research aims at increasing the efficiency of solar cells, enhancements in solar technology become achievable and crucial to its future viability.

WHAT IS THE LIFESPAN OF SOLAR CELLS?

The lifespan of solar cells has emerged as a significant consideration for consumers and manufacturers alike. Typically, well-designed silicon solar cells have a life expectancy ranging from 25 to 30 years, with many maintaining substantial power output even after this period. The initial efficiency is vital, but factors such as environmental conditions and installation quality play key roles in determining a solar cell’s longevity.

A crucial aspect of solar cell durability involves the protective coatings and materials used in assembly. High-quality tempered glass, combined with effective polymer films, can significantly enhance the cells’ resistance to environmental variables, including UV exposure and weather conditions. Additionally, ongoing advancements in material science are leading to new innovations that could possibly extend this lifespan further.

Market trends also indicate that warranties for solar cells are becoming more robust, often guaranteeing at least an 80% efficiency at the end of 25 years. This suggests that manufacturers have confidence in their products to deliver reliable performance over extended periods.

In essence, while numerous factors influence the lifespan, solar cells represent a cost-effective and long-term energy solution, contributing significantly to the growth of renewable energy solutions worldwide.

The journey towards manufacturing effective solar cells is an intricate process laden with critical details. By selecting optimal materials, implementing sophisticated doping techniques, applying protective coatings, and executing thorough quality control measures, innovative solar technology can flourish.

Encouraging continual research and development is essential for enhancements in efficiency and sustainability. The solar industry’s future is promising, with a clear trajectory toward incorporating more eco-friendly practices and materials, elevating its contribution to global energy solutions. As advancements continue, it is critical to address not only the effectiveness of solar cells but also their environmental impact, driving the adoption of renewable energy.

Through the integration of solar technology into everyday life, we can embrace a cleaner, more viable future that benefits individuals and communities. The importance of solar energy cannot be overstated in the context of combating global climate change and reducing dependence on fossil fuels. Thus, fostering progress in the solar sector serves as an imperative step toward achieving a sustainable energy model for generations to come.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-make-solar-cells/