To create round solar tubes, there are several essential steps to follow for ensuring efficiency and functionality. 1. Understand design principles, 2. Gather appropriate materials, 3. Construct the tube, 4. Install reflective surfaces, 5. Implement proper ventilation, 6. Complete the installation effectively. One key aspect involves the design principles, which significantly impact how the solar tubes capture and utilize sunlight. The shape should promote optimal sunlight absorption while facilitating efficient air circulation. Additionally, choosing high-quality materials such as resilient glass for the outer layer and thermal insulation for the interior will enhance the system’s efficiency and longevity. By focusing on these vital elements, anyone can successfully create effective round solar tubes that harness solar energy efficiently.

1. DESIGN PRINCIPLES

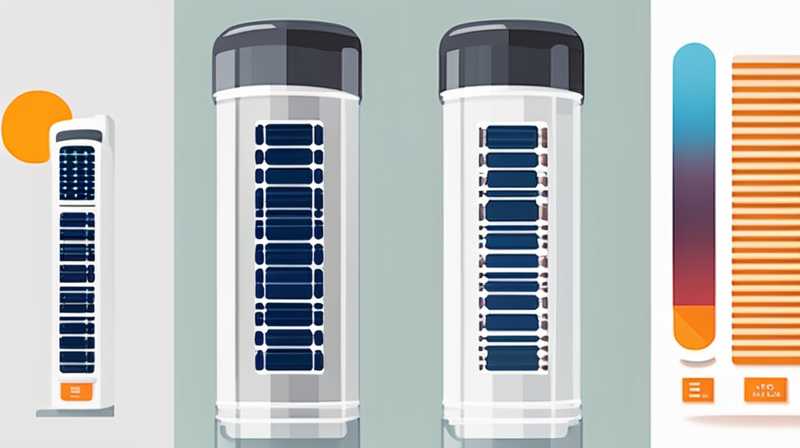

Creating round solar tubes necessitates a solid grasp of the underlying design principles. The fundamental idea revolves around deriving maximum energy from sunlight while ensuring structural integrity and functional efficiency. First, the version’s size should balance aerodynamics and space efficacy, permitting smooth airflow while preventing excessive heat loss. The diameter directly influences the overall efficiency, as a broader tube can capture more sunlight but may introduce challenges related to heat retention.

Moreover, the orientation plays a pivotal role in determining exposure to sunlight. Positioning the tube correctly according to the sun’s trajectory throughout the year is crucial. This involves conducting a site analysis to consider local climate conditions and shade patterns, thus enabling proper placement to maximize sunlight absorption.

MATERIAL CONSIDERATIONS

Selecting suitable materials is imperative for constructing durable and effective round solar tubes. Typically, high-quality glass serves as the outer layer due to its excellent transparency and weather resistance. This allows sunlight to penetrate efficiently while protecting the internal components from environmental factors.

Insulation comes next, as it is vital for retaining the heat generated inside the tube. Utilizing materials such as fiberglass or foam insulation ensures minimal energy loss, thereby amplifying the system’s efficiency. Additionally, reflectors should be strategically placed within the tube, often made of aluminum or mylar, to further enhance light capture and distribution.

2. CONSTRUCTION TECHNIQUES

Once the design and materials are firmly established, it’s time to delve into the construction techniques. Creating round solar tubes involves multiple steps: shaping the tube, installing internal components, and securing the space against external elements. First, shaping the tube can involve bending the chosen materials into a cylindrical form, ensuring a perfect fit for the intended dimensions. Precision in this phase guarantees that the components align correctly, which is essential for optimal energy absorption.

Furthermore, internal elements must be added carefully. These include the insulation layers and reflective materials, which are fundamental in driving the efficiency of the solar tube system. Each layer serves a unique purpose, requiring meticulous attention during installation to ensure proper alignment and sealing against leaks or air loss.

CONNECTING COMPONENTS

Attaching the different components is crucial for effective functionality. Fittings, seals, and connectors must be of high quality to create a robust assembly capable of withstanding wind, rain, and thermal expansion. Equally, ensure that reflective surfaces are affixed neatly to maximize efficiency by distributing the captured sunlight evenly.

Additional consideration should also be given to ventilation; adequate openings or ports may be required to allow excess heat to escape without disrupting the tube’s overall performance. The overall assembly should result in a seamless exterior, presenting an appealing appearance while being entirely functional.

3. INSTALLING REFLECTIVE SURFACES

Adding reflective surfaces inside the solar tube can profoundly affect its overall performance. These reflectors help direct sunlight towards the central insulating components. The aim is to maximize the utilization of each ray of sunlight captured. Thus, materials like aluminum with high reflectivity are often used, coated with special finishes to ensure durability against environmental exposure.

Applying the reflectors requires thorough assessment of the tube’s inner surface. Specifically, ensuring that the reflective materials are secured without gaps or overlaps is vital for optimal performance. Precision in positioning maximizes the concentration of sunlight directed toward the thermal core, allowing for effective heat generation within the tube.

MAINTAINING REFLECTIVITY

Maintaining the reflectivity of these surfaces is another critical component for long-term effectiveness. Over time, dust and grime can accumulate, diminishing the ability of reflectors to capture sunlight efficiently. Setting up a cleaning schedule to keep these surfaces clear is essential to ensure continuous peak performance. Quality construction paired with ongoing maintenance contributes significantly to the longevity of the solar tubing system.

4. FINAL INSTALLATION PROCEDURES

Transitioning from construction to installation involves several last procedures that require careful attention. Proper sealing and insulation at joints and connections will minimize potential energy losses and prevent water intrusion. Utilizing silicone-based sealants allows for durable connections while simultaneously providing flexibility to accommodate temperature fluctuations.

Ensuring proper placement according to initially gathered sunlight data is critical. This necessitates installation on rooftops, in yards, or areas with unobstructed southern exposure, thus optimizing solar energy absorption. Grounding and ensuring structural stability against winds or other environmental forces also enhances reliability.

TESTING PERFORMANCE

Conducting performance tests post-installation is significant. This aligns with ensuring the system operates as anticipated, verifying heat retention and sunlight capture efficiency. Measuring temperature gradients within the tube provides key insights into operational effectiveness and areas for improvement if necessary.

Ultimately, these final steps culminate in delivering a round solar tube that performs optimally while providing long-term energy efficiency.

FAQs

HOW DO ROUND SOLAR TUBES WORK?

Round solar tubes operate based on principles of solar thermal energy absorption. They capture sunlight through transparent glass or plastic tubes, which then heats the air or liquid within. This heated medium can then be used for various applications, including space heating or domestic hot water systems.

These tubes utilize reflective surfaces to direct sunlight towards the center, where thermal energy is collected. The design ensures minimal heat loss while accommodating natural ventilation, allowing for optimal performance in varying environmental conditions. Regular maintenance is necessary to maintain efficiency and ensure that dust and dirt do not obstruct sunlight.

WHAT MATERIALS ARE BEST FOR ROUND SOLAR TUBES?

Selecting appropriate materials is critical for effective construction and performance. High-quality glass or polycarbonate is ideal for the outer layer, providing excellent transparency and resilience against harsh weather conditions. Additionally, insulation materials like fiberglass or foam are essential for minimizing heat loss.

Reflective surfaces, typically made from aluminum or a similar material, enhance the amount of sunlight captured, while proper sealing and durable connectors ensure that the assembly withstands environmental factors. Overall, the superior materials used play a pivotal role in the longevity and efficacy of round solar tubes.

HOW CAN I IMPROVE THE EFFICIENCY OF MY ROUND SOLAR TUBES?

Several methods exist for augmenting the efficiency of round solar tubes. Monitoring positioning is paramount; ensuring the tubes are oriented correctly allows for maximum sunlight exposure throughout different seasons. Regular maintenance, including cleaning the reflective surfaces and ensuring seals remain intact, plays a vital role in optimal functionality.

Conducting performance tests helps track operational effectiveness, facilitating timely adjustments. Lastly, incorporating supplementary features, such as thermal storage solutions, may enhance energy capture and retention, leading to overall improved performance and utility.

The process of constructing round solar tubes integrates various elements ranging from design principles to materials, construction techniques, and installation procedures. Each segment plays a pivotal role in the overall efficiency and functionality of the solar energy system. By understanding these components, one lays the groundwork for an effective solar project. Employing high-quality materials ensures that durability accompanies efficiency while adequate maintenance will maximize performance longevity. Ultimately, harnessing solar energy via round tubes presents a viable solution in the transition towards renewable energy sources. Efficient energy use symbolizes a step forward in sustainability, offering environmental and economic benefits. Through dedication to careful design, construction, and ongoing performance assessment, round solar tubes can seamlessly integrate into energy solutions, promoting energy independence and reducing reliance on non-renewable sources. The shift towards greener living, through utilizing solar energy effectively, fosters a more sustainable tomorrow.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-make-round-solar-tubes/