To create a solar-powered car requires a synergistic combination of engineering, environmental awareness, and innovative thinking. This endeavor begins with 1. understanding the components necessary, 2. designing for efficiency, 3. selecting suitable materials, and 4. implementing effective systems for energy conversion. The most critical aspect involves the integration of solar panels into the vehicle, ensuring optimal sunlight absorption and energy retention for propulsion. Delving deeper, each component must be meticulously calibrated to achieve maximum performance while reducing waste.

Building a solar-powered vehicle not only supports sustainability but also fosters ingenuity among engineers and enthusiasts alike. Challenges such as weight management, power requirements, and grid compatibility arise, yet solutions exist within advancements in photovoltaic technology and energy storage.

Understanding the Components Necessary

The foundation of constructing a solar-powered vehicle lies in grasping various essential elements. A solar-powered car’s primary components include solar panels, battery systems, electrical motors, and controller systems.

Solar panels serve as the heart of the vehicle, converting sunlight into electricity through photovoltaic cells. Selecting high-efficiency solar panels is crucial, as they directly influence energy output. Factors such as panel orientation, shading, and surface cleanliness must also be managed to maximize energy production. The type of solar panel—monocrystalline or polycrystalline—affects not only the efficiency rate but also the overall cost of the solar system.

Battery systems are tasked with storing energy produced by the solar panels. Lithium-ion batteries are a popular choice due to their lightweight nature and superior energy density. These batteries must be paired with a battery management system to ensure optimal voltage and current regulation, thereby extending battery life. Preference should be given to batteries designed specifically for solar applications, as they tend to have longer lifespans and better thermal management capacities.

Designing for Efficiency

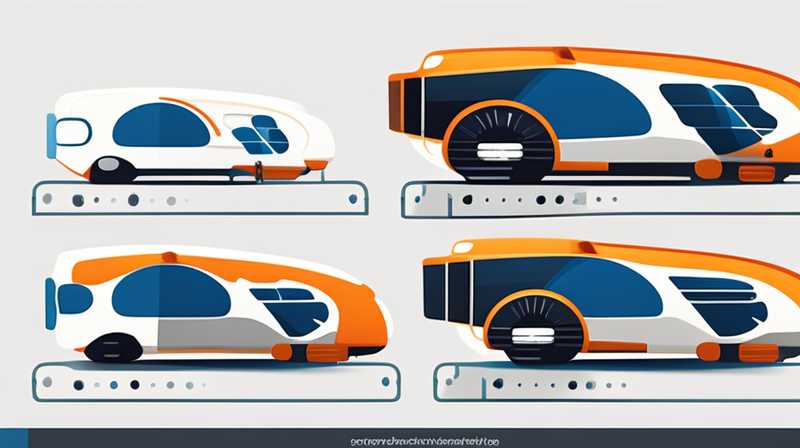

An efficient vehicle design plays an integral role in the success of a solar-powered car. Aerodynamics present a crucial aspect; vehicles designed with a streamlined shape experience less air resistance, thereby reducing the energy required to achieve motion.

Utilizing computer simulations during the design stage can identify potential aerodynamic improvements. Designers frequently study concepts such as drag coefficient and understand how vehicle shape impacts overall efficiency. Incorporating materials that minimize weight but offer considerable strength—like carbon fiber or aluminum—also contributes to better performance.

In parallel, solar-powered cars must incorporate state-of-the-art energy-efficient technologies. Strategies like regenerative braking can harness energy typically lost during braking by converting it back into usable power for the battery system. Moreover, implementing efficient lighting systems, such as LED technology, can significantly decrease the electrical demand on the overall system, allowing more energy to be funneled toward propulsion.

Selecting Suitable Materials

The choice of materials influences the effective performance and longevity of solar-powered vehicles. Materials must possess an ideal balance between lightness, strength, and cost-effectiveness.

Carbon fiber represents a prevalent choice, despite its higher cost, due to its remarkable strength-to-weight ratio, which allows for lighter structures without sacrificing stability. Aluminum is another commonly utilized material; it is more affordable yet cooperative in terms of fabrication and rigidity. Developing an understanding of the environmental implications of chosen materials is essential for creating a sustainable vehicle.

Additionally, the groundwork for the chassis and body must allow ample opportunities for integrating solar panels while maintaining structural integrity. Composite materials—formed from two or more constituent materials—can be beneficial in specific applications, presenting positive characteristics that exceed those of singular materials alone.

Implementing Effective Systems for Energy Conversion

Converting solar energy into propulsion encompasses various engineering disciplines, necessitating an in-depth understanding of electronic systems. The foremost step in this direction involves selecting an appropriate electric motor capable of transforming electrical energy into mechanical energy.

Brushless DC motors often emerge as the preferred choice for solar-powered vehicles due to their efficiency and longevity. Inline with advancements in motor technology, designers must evaluate performance parameters such as torque ratings and energy consumption. Understanding these variables ensures the electric motor complements solar energy input effectively.

Alongside the motor, the incorporation of a well-designed solar charge controller becomes vital. This controls the electrical flow between solar panels and batteries, preventing overcharging and providing essential insights through system monitoring. Such controllers act as gatekeepers, responsible for discerning the efficiency of energy transfer and maintaining optimal operation.

Conclusion

Embarking on the journey to create a solar-powered car encapsulates the integration of various engineering concepts, sustainable practices, and innovative thinking. The essence resides in understanding each segment—from choosing the most suitable solar panels and battery systems to designing for optimal aerodynamics, material selection, and energy conversion mechanisms. Mastery of each component can significantly enhance performance and battery life while minimizing environmental impact. This venture stimulates curiosity and creativity in engineering, allowing individuals and groups to contribute to a greener future through practical applications of renewable energy technologies. The process may present challenges regarding weight management, energy requirements, and technical expertise, yet advancements in materials and systems catalyze the feasibility of building a renewable vehicle. Herein lies not just an engineering project but an opportunity for advocacy and education concerning renewable energy. Harnessing sunlight for transportation aligns with future trends targeting sustainability and resource efficiency, urging communities to rethink transportation methods profoundly. Solar-powered vehicles represent more than mere transport; they signify a pivotal movement towards eco-friendly living, offering insights into energy independence and technological advancement. Investing in solar car technology paves the way for greener solutions that can foster widespread adoption, ultimately steering society toward a sustainable future.

FREQUENTLY ASKED QUESTIONS

WHAT TYPES OF SOLAR PANELS ARE BEST FOR SOLAR-POWERED CARS?

Solar panels play a pivotal role in the functionality of solar-powered vehicles. Two primary types—monocrystalline and polycrystalline—are commonly utilized, each with distinct characteristics and advantages. Monocrystalline panels are known for their higher efficiency rates, often exceeding 20%, given their single crystal structure that allows greater energy production per square meter. This efficiency makes monocrystalline panels ideal for applications where space is limited, such as the surface of a car.

On the other hand, polycrystalline panels typically present a more affordable option, although they possess slightly lower efficiency ratings, generally around 15-17%. Their energy output can be suitable, especially in vehicles designed with larger surface areas for solar panel installation. When considering your options, evaluate the specific energy needs of the vehicle and the available surface area for solar panels. Various factors including cost, installation conditions, and expected solar exposure should inform the decision regarding panel type. Ultimately, choosing the right solar panels aligns with not only space constraints but also the overarching energy efficiency goals of the solar vehicle project.

HOW LONG CAN A SOLAR-POWERED CAR RUN ON A SINGLE CHARGE?

The duration a solar-powered vehicle can operate on a single charge varies substantially based on several factors such as battery capacity, driving conditions, and energy consumption. For instance, if equipped with a well-designed lithium-ion battery, a solar car can typically achieve a range of approximately 100 to 300 miles on a full charge, depending on the specific energy storage specifications and efficiency.

It’s crucial to consider real-world conditions impacting this calculation. Aerodynamic factors, vehicle weight, driving speed, and additional features like air conditioning or heating can drain battery life more rapidly than anticipated. A solar vehicle operating under ideal conditions, such as during optimal sunlight and on flat terrains, may extend its distance traveled significantly. Furthermore, incorporating regenerative braking can enhance the vehicle’s efficiency by converting kinetic energy back into stored energy during braking events, potentially extending the range significantly. Thus, accurately assessing the battery’s state of charge alongside external environmental factors helps determine how long a solar-powered car may effectively run before needing a recharge.

WHAT CHALLENGES COME WITH BUILDING A SOLAR POWERED CAR?

Constructing a solar-powered vehicle presents several challenges that require careful consideration and innovative approaches. One significant hurdle is energy efficiency; ensuring the solar panels efficiently convert sunlight into usable electricity is paramount. Selecting the right panel technology and system design can influence energy capture significantly.

Another challenge resides within weight management. The weight of components such as batteries, motors, and the vehicle structure must be optimized to enhance overall performance. Excessive weight leads to higher energy consumption, negating some benefits of utilizing solar energy. Engineers must diligently work to select lightweight materials without compromising structural integrity—often requiring trade-offs and compromises during the design process.

Moreover, integrating all components cohesively to operate seamlessly is another challenge. Each element must communicate effectively with others, particularly the energy management system that governs the flow of electricity. Compatibility issues between various systems, including charge controllers and electric motors, can lead to performance fluctuations. Addressing these challenges necessitates ongoing research and development efforts, emphasizing continuous innovation in solar vehicle technology amidst the pursuit of sustainable transportation alternatives.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-make-a-solar-powered-car-straight/