1, Ensure proper materials are gathered, 2, Select appropriate solar cells, 3, Assemble the charging circuit, 4, Design and create the casing, 5, Test and optimize performance.

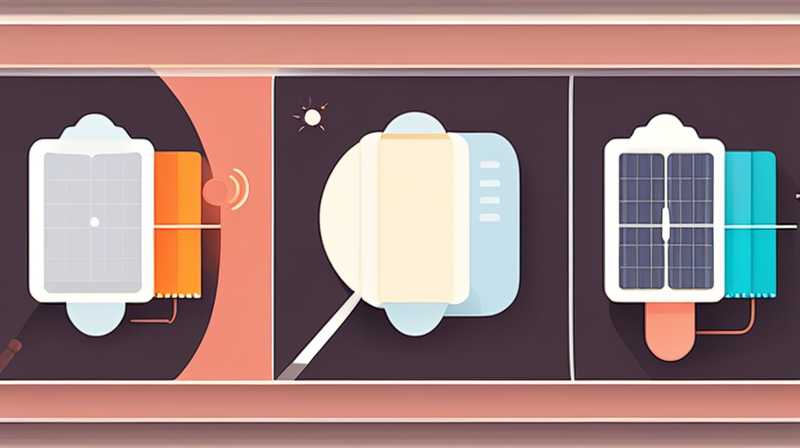

Creating a solar light charger involves several important steps, each with its own specific requirements to ensure efficiency and functionality. First, gathering the right materials is crucial. You will need solar cells, a rechargeable battery, a charge controller, diodes, and an enclosure to protect the components. Each of these parts performs a vital role. For instance, solar cells convert sunlight into electrical energy, while the battery stores this energy for later use.

Next, determining the type and configuration of solar cells is paramount. Most commonly, monocrystalline or polycrystalline silicon cells are used based on their efficiency rates and cost. The arrangement of these cells will ultimately affect the overall output and efficiency of the system. Once the solar cells are selected, building the charging circuit is the next step. This circuit regulates the energy flow from the solar cells to the battery and includes a charge controller to prevent overcharging.

After assembling the circuit, creating a sturdy casing offers protection from environmental elements and also aids in the aesthetics of your solar charger. Finally, testing the entire setup ensures that the solar light charger operates correctly and identifies any areas for potential improvement. Optimizing these steps can lead to a more efficient solar light charger, which is beneficial for various applications.

MATERIAL COLLECTION

Acquiring the right components to build a solar light charger is a foundational step that dictates the overall success of the project. Firstly, solar cells are essential components that will absorb sunlight and convert it into electricity. Technically, monocrystalline solar cells are known for their higher efficiency and space-saving qualities, while polycrystalline offers a cost-effective solution but at a slightly lower efficiency level.

In addition to solar cells, a rechargeable battery is crucial for storing the converted electrical energy. Lithium-ion batteries are a popular choice due to their higher energy density and longer lifecycle compared to other options like lead-acid batteries. Furthermore, a charge controller must be incorporated to manage the voltage and current coming from the solar cells, thereby protecting the battery from overcharging or even discharging on cloudy days.

Equally important are the diodes, which allow the flow of electricity in one direction only, preventing reverse current that could damage the solar cells or battery. Wires, soldering tools, and a suitable enclosure made from durable material contribute to construction and protection against weather elements. Having all necessary materials ready ensures a smoother assembly process and minimizes delays that may arise from last-minute procurement of materials.

SELECTING SOLAR CELLS

The selection process of solar cells plays an integral role in the efficiency of the solar light charger. Understanding the performance metrics of solar cells, such as their conversion efficiency, temperature coefficient, and power ratings, directly influences the effectiveness of the charger. For instance, monocrystalline solar cells typically exhibit a higher efficiency rating, often exceeding 20%. This provides a significant advantage when space is constrained, enabling more energy to be captured per square foot.

Additionally, installation space considerations must align with solar cell choice. If installation space is ample, one may prefer using polycrystalline cells, which tend to be cheaper but occupy larger areas for equivalent output. Evaluating local sunlight exposure and geographic location also affect cell selection. Regions with more sunlight could benefit from a higher number of lower-efficiency cells, while places with limited sunlight may necessitate fewer but more efficient cells to maximize energy capture.

Another consideration includes the durability and lifespan of the solar cells. Opting for reputable brands can enhance reliability since these products will often come with warranties and proven performance metrics. Furthermore, the orientation and angle at which the solar cells are installed can significantly impact the total energy captured, making it imperative to strategize installation appropriately based on geographic and environmental factors.

ASSEMBLING THE CHARGING CIRCUIT

Constructing the charging circuit serves as a pivotal step to ensure that the flow of electricity from the solar cells to the battery is regulated effectively. Understanding the role of each component in the system is essential. The charge controller manages the electricity output and input, preventing overcharging from the solar cells while allowing the battery to discharge at safe rates.

Wiring is also a critical element within this circuit; it must be rated for the expected current flow to prevent overheating or potential short circuits. To ensure optimal performance, soldering connections must be done with care to establish strong conductive pathways. Furthermore, it’s beneficial to install diodes close to the solar cells, as this placement minimizes the distance that reverse current has to travel in case of a power drop at night.

Once the connections are established, conduct thorough testing to verify that the circuit operates as intended. This can involve simulating varying light conditions to observe how well the solar cells convert light into electrical energy and whether the charge controller effectively manages this energy flow. Any inconsistencies observed could indicate issues with connections or the components themselves, necessitating either adjustments or replacement of parts. Testing not only improves operational reliability but also ensures maximum safety in the device’s use.

DESIGNING THE CASSING

Creating a protective casing is essential for a solar light charger to ensure its longevity and durability against the elements. Choosing material for the casing is of utmost importance; it must be weather-resistant while being sturdy enough to withstand impacts. Many individuals opt for materials such as ABS plastic or aluminum due to their weatherproof characteristics and lightweight nature.

Furthermore, the design of the casing should consider ventilation, as batteries can generate heat during both charging and discharging cycles. Incorporating vents allows airflow, which helps to maintain the battery’s optimal operating temperature. Adequate drainage holes can also prevent water accumulation, significantly reducing the risk of damage to internal components in the case of rain or snow.

In addition to practical considerations, aesthetic factors should not be overlooked. A well-designed casing can reflect personal style, with various color options and finishes available that could enhance the charger’s visual appeal. Nevertheless, the design must not compromise functionality; keeping the solar cells exposed maximizes their ability to capture sunlight while protecting the circuit and battery within. It is also advisable to utilize a clear cover for solar cells, as this allows sunlight to penetrate while offering an additional protective layer against debris, dirt, and vandalism.

TESTING AND OPTIMIZING PERFORMANCE

The performance evaluation stage is crucial and should not be underestimated. Conducting rigorous tests on the assembled solar light charger allows one to verify that all components are functioning together effectively and efficiently. This typically involves using a multimeter to gauge voltage levels, ensuring that the flow of electricity aligns with expectations and specifications outlined during the planning phase.

Experimenting under different conditions can reveal potential inefficiencies within the setup. For example, testing in varying light conditions can help determine if the positioning of the solar cells requires adjustment. If performance is lagging on cloudy days, it might suggest that the solar cells are not capturing enough energy. So, further optimization may be necessary, such as recalibrating angles or changing the configuration of the cells.

Additionally, the battery’s capacity must be quantified during testing. It is vital to assess that the battery can hold a charge adequately for its intended purpose. Regularly monitoring charge and discharge cycles will assist in extending the lifespan of the battery while ensuring consistent performance for the solar light charger. Finding optimal parameters allows not just for functional operation, but also for adaptability in real-world usage scenarios.

FAQs

WHAT TYPE OF SOLAR CELLS SHOULD I USE FOR MY CHARGER?

The choice of solar cells primarily hinges on efficiency requirements, budget constraints, and available space. Monocrystalline solar cells, known for their higher efficiency, are usually preferred for limited space. They can perform well even in lower light conditions and often have longer lifespans than alternatives. Polycrystalline solar cells may also be suitable as they offer a more cost-effective solution, though their efficiency is generally lower. Many opt for a combination of both based on specific needs and conditions. Additionally, thin-film solar cells are another possibility, though they can be less efficient overall.

HOW DO I DETERMINE THE CAPACITY OF THE BATTERY NEEDED?

Determining the necessary battery capacity depends on several factors: the wattage of devices being charged and expected usage frequency. A good rule of thumb is to consider the total daily power requirement, calculated as wattage multiplied by hours of use. Once a total is established, select a battery that can accommodate that capacity while also reserving some extra capacity to enhance battery lifecycle and performance. Generally, lithium-ion batteries are recommended due to their higher energy density and efficiency.

CAN I USE MY SOLAR LIGHT CHARGER FOR OTHER DEVICES?

Yes, provided that the output specifications of the solar light charger align with the requirements of the devices you intend to use. Assess the voltage and current ratings of both your charger and device before connecting them. Most solar chargers can be designed to support multiple device types. If you wish to charge devices with varying specifications, employing a DC-DC converter can assist in providing the correct power levels.

Final Thoughts

Building a solar light charger embodies a rewarding and educational experience that deepens one’s understanding of renewable energy technologies. By carefully executing the steps from material collection to performance testing, one can craft a device that not only serves personal needs but also contributes positively to the environment. The significance of solar technology in today’s energy landscape cannot be overstated. Investing time and effort into this project yields a sustainable solution, demonstrating a commitment to cleaner, more renewable energy sources.

Working with renewable technologies fosters deep appreciation and respect for natural resources. Such initiatives can inspire others in the community to take similar steps towards sustainable energy solutions, ultimately amplifying the collective impact on the environment. Furthermore, the knowledge gained through building a solar light charger can pave the way for future innovations, whether that involves scaling the project, integrating additional functionalities, or even venturing into completely new areas of renewable energy.

Through careful selection of materials, astute design choices, and diligent testing, a high-functioning solar charger can be constructed, enhancing both practical applications and environmental consciousness. The journey from conception to implementation can indeed be rewarding and valuable, encouraging others to harness the sun’s energy in innovative and efficient ways.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-make-a-solar-light-charger/