To create a solar charging panel independently, one requires a blend of essential components, specific tools, and a thorough understanding of solar technology. 1. Gather materials, including solar cells, a backing board, wiring, and a charge controller. 2. Assemble components by connecting cells in series or parallel according to desired voltage and amp output. 3. Integrate charge controller to regulate power flow effectively and prevent battery overcharging. 4. Encapsulate construction to ensure durability and resilience against environmental elements. Focusing on quality throughout each step enhances efficiency.

1. UNDERSTANDING SOLAR CELL TECHNOLOGY

Solar energy harnesses sunlight through photovoltaic cells, converting light energy into electric power. These cells are the building blocks of solar panels, engineered from materials like silicon, which exhibit semiconductor properties. Photovoltaic technology signifies a remarkable advancement in energy generation, enabling sustainable power solutions across various applications, from residential setups to extensive solar farms.

The efficiency of solar cells is dependent on several factors, such as their composition, quality, and the strength of sunlight. Monocrystalline cells, known for their superior efficiency, consist of single-crystal silicon and require complex manufacturing processes. Polycrystalline cells are less efficient yet more cost-effective, made from multiple silicon crystals. Understanding these variations allows enthusiasts to choose the right type based on budget and specific energy needs.

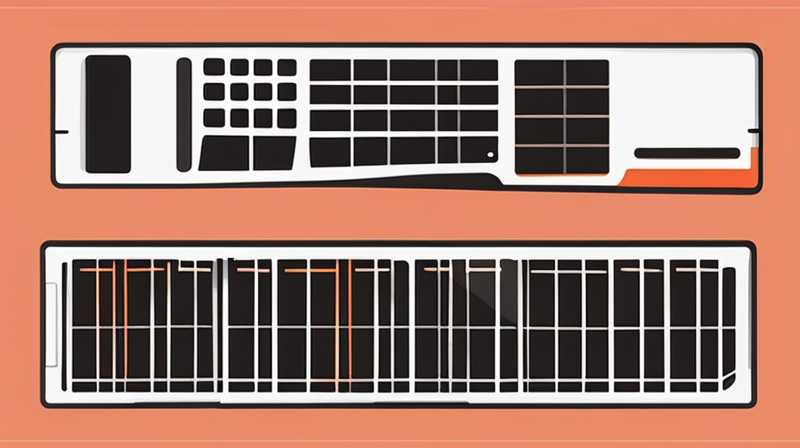

2. GATHERING MATERIALS REQUIRED FOR DIY SOLAR PANELS

Embarking on the journey of creating a solar charging panel starts with assembling an appropriate arsenal of materials. High-quality solar cells represent the most crucial component, as their performance directly impacts energy output. Typically, individual cells can be purchased from reputable suppliers or online marketplaces, available in different voltages and wattages. Selecting cells designed for the intended application ensures compatibility and efficiency.

Beyond solar cells, a sturdy backing board is essential. Plywood or polycarbonate sheets are frequently employed due to their durability and lightweight characteristics. This backing supports the solar cells and safeguards them from environmental damage. Additionally, wiring and connectors are paramount for establishing connections between cells. Correct gauge wiring promotes safety and efficiency, minimizing energy losses across connections. A charge controller is also necessary for regulating the flow of electricity, ensuring batteries are charged safely without overloading.

3. TOOLS NECESSARY FOR CONSTRUCTION

Crafting a solar charging panel necessitates an array of tools that enhance both precision and efficiency during assembly. Soldering iron, along with solder, is indispensable for securely joining wires to solar cells. Effective soldering assures long-term reliability, minimizing the risk of disconnections or faults that could degrade performance.

Moreover, a multimeter becomes a vital asset in this endeavor. It assists in measuring voltage, current, and resistance throughout the circuit, ensuring optimal performance during the testing phase. Accurate measurements enable adjustments that optimize the solar panel’s output. Various cutting tools, including a saw and utility knife, may be required for trimming components to fit the desired dimensions. Protective equipment such as goggles and gloves will ensure personal safety while working with electrical materials.

4. ASSEMBLING SOLAR CELLS AND CONNECTIONS

Once the necessary components and tools are assembled, the assembly process can begin. Start by adhering the solar cells to the backing board in a pre-determined layout. The most common configurations involve arranging cells in series or parallel. Connecting cells in series increases voltage while maintaining the same amperage, whereas parallel connections retain the voltage level while boosting the total current output. The choice of configuration significantly affects performance based on intended use.

After placing the solar cells, connecting wires securely through soldering is essential. Properly securing each connection minimizes resistance and energy loss. It is advisable to use a multimeter periodically to test voltage outputs after each connection, ensuring that the setup remains within expected operational parameters. Once the cells are connected, making additional connections to the charge controller and battery becomes the next step, allowing for energy storage in a safe and manageable manner.

5. INSTALLING A CHARGE CONTROLLER

Equipping the solar panel with a charge controller is a critical aspect of managing energy flow. Charge controllers function to regulate the voltage and current generated by the solar cells, safeguarding the connected batteries from damage due to overcharging. By constantly monitoring the battery’s state, these controllers maintain optimal charging levels, extending battery life and reducing the risk of fires or system failures.

Several types of charge controllers exist, including PWM (Pulse Width Modulation) and MPPT (Maximum Power Point Tracking). PWM controllers are simpler and more affordable, suited for smaller systems. In contrast, MPPT controllers, while more costly, offer higher efficiency, particularly in larger installations or when operating in less-than-ideal sunlight conditions. Selecting the appropriate controller is pivotal, based on the anticipated power demands and budget constraints.

6. ENCAPSULATING AND PROTECTING THE ASSEMBLY

After successful assembly and testing, protecting the solar panel is paramount for longevity. Encapsulation involves sealing the panel components to ward off environmental hazards, including moisture, dust, and debris. Using a transparent, weatherproof material such as glass or polycarbonate over the solar cells shields them while allowing optimal light penetration.

The edges of the panel should also be sealed with silicone or an equivalent sealant to prevent moisture ingress, which could lead to corrosion or cell damage. This protective layer serves dual purposes: enhancing durability and maintaining efficiency. Ensuring that the panel is mounted on a stable structure away from direct impacts or heavy stress further contributes to its lifespan.

7. TESTING AND EVALUATING INDIVIDUAL PERFORMANCE

Testing the solar charging panel’s performance after assembly is crucial to verify its functionality and efficiency. Initially, connect the panel to a multimeter, measuring the output voltage during direct sunlight conditions. This check assesses both individual solar cell performance and the effectiveness of all connections. Voltage readings should align with prior estimations based on cell configuration.

Additionally, evaluate the current output while charging a battery under controlled conditions. Recording these readings over time provides insight into the panel’s energy generation capabilities and efficiency. Making necessary adjustments to the configuration or connections based on testing results optimizes overall performance. Establishing a routine testing mechanism ensures that any degradation or faults are promptly addressed.

8. MAINTAINING YOUR SOLAR CHARGING PANEL

Maintaining a solar charging panel ensures its sustained performance over time. Regularly cleaning the panel surface is essential, removing debris, dust, and dirt that may accumulate and obstruct sunlight access. Employing a soft cloth and mild soap with water suffices for cleaning purposes, avoiding harsh chemicals that may damage the panel surfaces.

It is also beneficial to periodically inspect connections and solder points, ensuring they remain secure and free from corrosion. Over time, certain components may require replacement, especially if they exhibit signs of wear or reduced functionality. Keeping meticulous records of maintenance activities and any adjustments made allows for better long-term management and planning for future upgrades.

9. COST-BENEFIT ANALYSIS OF DIY SOLAR PANELS

Engaging in the construction of solar charging panels can yield significant financial advantages when compared to purchasing pre-assembled units. Analyzing the overall cost of materials and construction reveals potential savings, particularly for those with multiple energy requirements. The choice between assembling one’s system and purchasing one will depend significantly on the anticipated energy consumption and available resources.

While initial investments for the materials may seem substantial, the long-term benefits of reduced energy bills and the ability to harness renewable energy vastly outweigh these costs. Moreover, becoming self-reliant in energy production fosters independence and mitigates reliance on fossil fuels, a crucial factor for environmentally conscious individuals. Evaluating potential savings over time emphasizes the practicality of investing in a DIY solar charging panel.

10. FUTURE TRENDS IN SOLAR TECHNOLOGY

The future of solar technology emphasizes continuous innovations aimed at enhancing efficiency, sustainability, and affordability. Trends such as BIPV (Building-Integrated Photovoltaics) are gaining prominence, incorporating solar cells seamlessly into building materials, creating dual-purpose structures that generate energy while serving as conventional building elements. This avenue promises to revolutionize the design aspects of architecture.

Furthermore, advancements in energy storage technology, such as lithium-ion batteries, enhance the practicality of solar power by allowing for efficient energy retention for later use. Changes in legislation and societal attitudes towards renewable energy generation provide strong momentum for future growth. Understanding these trends allows individuals and businesses to anticipate coming changes, positioning themselves strategically within the evolving energy landscape.

FREQUENTLY ASKED QUESTIONS

WHAT ARE THE BENEFITS OF BUILDING YOUR OWN SOLAR PANEL?

Constructing your own solar panel offers multiple advantages. Cost Efficiency stands as a primary benefit; individuals can save significant sums by sourcing materials and assembling components independently rather than purchasing complete systems. This process fosters a deeper understanding of solar technology, empowering users to troubleshoot and optimize the system according to personal energy needs.

Furthermore, the ability to customize configurations based on energy requirements is paramount. This customization allows users to tailor their solar panels for specific applications, whether for charging devices, powering lights, or contributing to larger energy systems. Additionally, engaging in this DIY project promotes a sustainable lifestyle while reducing reliance on traditional energy sources, ultimately contributing positively to the environment.

HOW MUCH TIME DOES IT TAKE TO CONSTRUCT A SOLAR CHARGING PANEL?

The time required to construct a solar charging panel can vary based on several factors, including the complexity of the design and the individual’s previous experience with similar tasks. An average DIY enthusiast may spend several hours to a couple of days completing the project from start to finish.

Typically, gathering materials and preparing tools takes time, followed by the assembly phase, which includes soldering connections and properly securing components. Once assembled, testing the panel and making necessary adjustments could extend the timeframe. Allocating sufficient time for each stage ensures a thorough construction process, allowing for higher quality and increased efficiency in the final product.

WHAT IS THE ESTIMATED COST OF MATERIALS NEEDED FOR DIY SOLAR PANELS?

The cost associated with constructing a solar charging panel varies considerably depending on the extent of the system and the selected components. On average, essential materials, including solar cells, wiring, connectors, and the charge controller, may range from $100 to $300 for a small-scale panel.

More sophisticated setups may cost more, especially if utilizing higher-efficiency cells or advanced charge controllers. It is crucial to evaluate options based on budget constraints and desired performance. Allocating funds effectively while sourcing materials from reliable suppliers remains central to maximizing return on investment while optimizing energy generation capabilities.

CONCLUDING THOUGHTS ON DIY SOLAR PANELS

The journey of crafting your own solar charging panel epitomizes empowerment through knowledge and sustainability. Understanding the intricacies of solar technology equips individuals not only to tackle the challenges of energy independence but also fosters a greater appreciation for renewable resources. By meticulously gathering materials, employing appropriate tools, and carefully crafting each component, one can establish an effective energy generation system tailored to personal needs. Continuous learning through testing, maintenance, and adaptation ensures optimal performance over time. As the landscape of renewable energy evolves, engaging in such endeavors becomes increasingly beneficial, providing not only financial savings but also a profound commitment to environmental stewardship. Advocating for renewable energy encourages wider societal shifts towards sustainability, inviting collective efforts to transition away from fossil fuel dependency. The implications of creating one’s solar panel extend beyond personal gratification; they foster movements towards global initiatives promoting renewable energy solutions and combating climate change. Ultimately, the DIY approach to solar energy illustrates the potential of individuals to instigate positive change, encouraging others to explore alternatives towards a sustainable future.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-make-a-solar-charging-panel-yourself/