To successfully flush a self-priming pump using solar energy, one must consider the following critical components: 1. Understanding the self-priming mechanism, 2. Solar energy integration, 3. Proper flushing procedures, and 4. Maintenance and monitoring systems. Self-priming pumps utilize vacuum pressure to draw liquid into the pump casing, simplifying initial setup and operation. When integrating solar energy, it’s essential to harness sufficient solar power to ensure the pump operates efficiently. The flushing procedure should also be executed carefully to prevent damage to the system. Regular maintenance and monitoring will ensure optimal performance and prolong the pump’s lifespan.

1. UNDERSTANDING THE SELF-PRIMING MECHANISM

Self-priming pumps are ingeniously designed to automatically create a vacuum that enables the fluid to be drawn into the system without requiring priming intervention. This fundamental feature sets them apart from traditional pumps, which typically necessitate manual priming efforts before operation. To truly grasp how these pumps function, it is pivotal to delve into the principles of fluid dynamics that govern the process.

A self-priming pump operates by utilizing an impeller that spins rapidly within the pump casing. This rotational motion creates a low-pressure area, effectively sucking the fluid into the pump. As the impeller continues to turn, the fluid is pushed out through the discharge port, creating a continuous flow. This method eliminates the necessity of filling the pump casing with liquid before startup, making it particularly beneficial for handling fluids in various applications, including agricultural irrigation and drainage systems. Understanding this mechanism lays the groundwork for implementing solar energy solutions effectively.

2. SOLAR ENERGY INTEGRATION

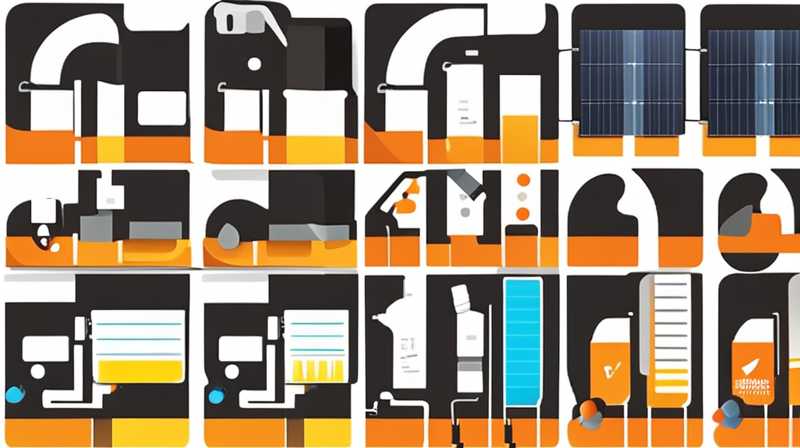

Integrating solar energy into the operation of a self-priming pump involves utilizing solar panels and associated inverter systems to harness sunlight. Solar panels convert solar irradiation into electricity, which can then be used to power the pump. The efficiency of this system hinges on several factors, including the type of solar panels selected, geographical location, and the overall solar potential available in a given area.

Solar panel technology has advanced significantly in recent years, allowing for greater efficiency and output. There are various types of panels available, such as monocrystalline, polycrystalline, and thin-film, each with distinct advantages. Monocrystalline panels, for example, offer higher efficiency rates and take up less space, making them suitable for locations with limited area. On the other hand, polycrystalline panels are more cost-effective, albeit slightly less efficient.

When choosing the solar energy system for a self-priming pump, it is crucial to calculate the daily energy requirements of the pump. One must consider factors like the pump’s power consumption, average runtime per day, and potential energy losses associated with system conversion. This analysis aids in determining the size and number of solar panels required to achieve reliable performance.

3. PROPER FLUSHING PROCEDURES

Executing the flushing procedure for a self-priming pump requires careful attention to detail to ensure optimal function and minimize potential damage. Flushing serves to clean the system by removing any residues, debris, or contaminants, thereby maintaining the pump’s efficiency. Before initiating the flushing operation, it becomes necessary to prepare the pump, ensuring that it’s switched off and disconnected from the solar energy source for safety.

It is essential to select an appropriate flushing fluid, typically water, although specific applications may call for specialized cleaning agents. The choice of flushing fluid depends on the type of material the pump has been designed to handle. One way to introduce the flushing fluid into the pump is by utilizing a temporary inlet connection. By filling the pump casing completely, the goal is to ensure that the pump is effectively purged of any stagnant liquid or contaminants that can negatively impact performance.

Subsequently, when the flushing begins, it is advantageous to use a low-speed setting to allow the fluid to circulate throughout the system. This gradually clears any remaining debris while preventing excessive wear on the impeller and casing. Following the initial flushing, an inspection of the system is warranted to assess the effectiveness of the procedure and ensure that no obstructions remain.

4. MAINTENANCE AND MONITORING SYSTEMS

Once the self-priming pump has been successfully flushed, a robust maintenance and monitoring routine should be established to maximize its longevity and secure efficient operation. Regular inspections facilitate early detection of potential issues, such as wear on components or build-up of sediment, which could lead to reduced efficiency or pump failure if left unattended.

Creating a maintenance schedule involves setting specific intervals for inspections and servicing based on the pump’s application and operational conditions. Key components to monitor include the impeller, seals, and the casing. Additionally, examining the solar energy system for optimal performance—ensuring panels remain clean, connections are secure, and batteries (if used) are properly charged—is vital for an uninterrupted energy supply.

Advanced monitoring systems can be integrated into the pump setup, allowing operators to track performance metrics in real-time. Technology such as IoT (Internet of Things) sensors can measure parameters like flow rate, operating temperature, and pressure levels. These smart systems send alerts to operators in case of anomalies, facilitating quick interventions and reducing downtime.

SOLAR ENERGY FLUSHING FAQS

WHAT IS A SELF-PRIMING PUMP?

Self-priming pumps are specialized types of centrifugal pumps designed to be capable of drawing fluid into the pump without the need for manual priming. These pumps create suction through the rotation of their impellers, allowing them to efficiently perform in various applications ranging from irrigation systems to water transfer processes. Their design optimizes performance by eliminating air pockets in the system, enabling them to operate effectively even when locations experience fluctuating fluid levels. The self-priming feature is particularly advantageous in scenarios where consistent priming would be cumbersome. A properly functioning self-priming pump can significantly enhance operational efficiency, making it a preferred choice for diverse industries.

HOW DOES SOLAR ENERGY POWER A SELF-PRIMING PUMP?

Solar energy powers a self-priming pump through a system of solar panels that convert sunlight into electrical energy. The installation of solar panels linked to an inverter system enables the conversion of direct current (DC) electricity from the panels into alternating current (AC), which is necessary for most pumps. To ensure sustainable operation, the solar energy system must be sized appropriately, considering factors such as pump power requirements and daily operational hours. Depending on the solar potential of the location, the number of solar panels needed may vary. Efficient solar energy utilization not only reduces reliance on traditional power sources but also fosters environmentally friendly practices while minimizing operational costs associated with energy consumption.

WHAT ARE THE BENEFITS OF FLUSHING A SELF-PRIMING PUMP?

Flushing a self-priming pump yields numerous benefits that contribute to its optimal functionality and durability. Through the flushing process, users effectively remove residual liquids, sediments, and contaminants, which can accumulate over time, leading to blockage or inefficiency in the pumping operation. Maintaining a clean pump system promotes improved flow rates and extends the life of critical components, such as the impeller and casing. Moreover, flushing can prevent the potential development of corrosive elements, further safeguarding the pump against deteriorative effects. Overall, a routine flushing regime cultivates a proactive approach to maintenance, ensuring long-term performance and reducing the risk of unexpected breakdowns.

Operating a self-priming pump powered by solar energy presents a unique intersection of technology and sustainability. By grasping the intricacies of the self-priming mechanism, seamlessly integrating solar energy, implementing meticulous flushing procedures, and instituting rigorous maintenance and monitoring practices, users can achieve remarkable performance from their systems. These steps not only ensure the pump’s efficiency but also foster an eco-friendly approach to water management, crucial in today’s climate-conscious landscape. An increased reliance on renewable energy sources, such as solar, signifies not only a pivot towards sustainability but also an acknowledgment of the growing importance of self-sufficiency in water management. Comprehensively understanding how to optimize the use of solar energy in flushing self-priming pumps can ultimately enhance project viability. It reflects a commitment to leveraging advanced technologies to meet pressing resource management challenges while prioritizing both operational efficiency and environmental responsibility. Achieving a balance between technological advancement and eco-conscious practices is essential for sustainable development, paving the way for innovative solutions that cater to evolving demands. The commitment to maintaining, optimizing, and effectively harnessing the power of solar energy ensures that users not only reap immediate benefits but also contribute positively to the broader context of global resource sustainability. This forward-thinking approach exemplifies the remarkable possibilities that arise through the intelligent integration of technology, sustainable energy sources, and traditional systems, ultimately leading to the enhancement of resource management practices in various sectors.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-flush-the-self-priming-pump-with-solar-energy/