To effectively drain the circulating fluid in solar energy systems, several strategic approaches can be employed. 1. Understanding the Fluid Dynamics, involves grasping how fluids circulate within solar thermal systems, 2. Selecting Appropriate Drainage Methods, necessitates choosing techniques such as gravity drainage or pump-assisted systems, 3. Implementing Safety Precautions, ensures minimal risk during the draining process, and 4. Regular Maintenance Practices contributes to the longevity and efficiency of solar installations. Among these, understanding the fluid dynamics is critical; it lays the groundwork for designing effective drainage solutions, considering factors like system layout, fluid properties, and environmental influences.

1. UNDERSTANDING THE FLUID DYNAMICS

Solar energy systems, particularly solar thermal installations, utilize circulating fluid to transfer heat collected from sunlight into a usable form of energy. This fluid can be water or a specialized heat transfer fluid. Fluid dynamics in this context refers to the behavior and movement of this fluid through the system, which involves several complex principles and mechanisms.

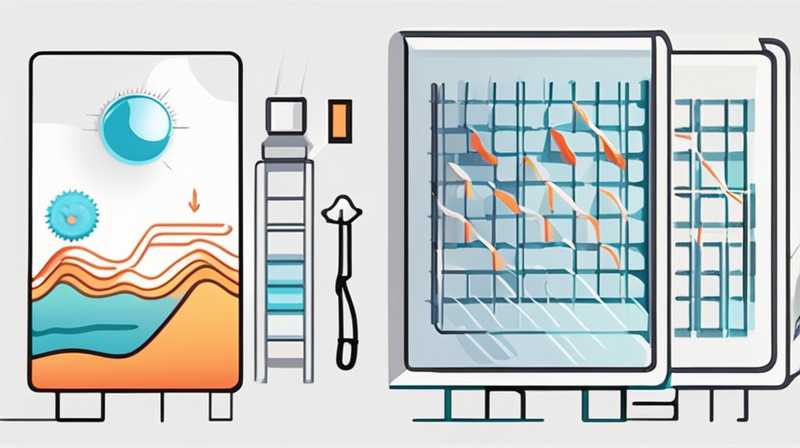

The configuration of the solar panels, the layout of the piping, and the overall system design significantly impact the fluid’s flow characteristics. For instance, in a closed-loop system, the fluid continuously circulates between the solar collectors and storage tanks, relying on gravity and pump systems to facilitate movement. Understanding these dynamics allows technicians to predict potential blockages, assess pressure gradients, and determine the most efficient means of draining the system when necessary.

Moreover, factors like temperature changes and fluid viscosity also play critical roles in this process. As the temperature of the fluid increases, its viscosity decreases, which affects how easily it can be drained. Therefore, any efforts to drain circulating fluids must account for these variations, ensuring that the system is operated efficiently during both heating and drainage phases.

2. SELECTING APPROPRIATE DRAINAGE METHODS

Choosing the right drainage technique is pivotal in effectively managing circulating fluids within solar energy systems. Two primary methods include gravity drainage and pump-assisted drainage systems. Each of these methods has its advantages and considerations that must be understood.

Gravity drainage relies on the natural force of gravity to facilitate the flow of fluid downwards from the system into a designated drainage point. This technique is straightforward and energy-efficient as it does not require additional machinery, thereby reducing operational costs. However, its efficiency can be compromised by system geometry; for example, if there are horizontal or upward runs in the piping, gravity drainage may not effectively remove all fluid.

On the other hand, pump-assisted drainage systems utilize mechanical pumps to actively remove fluid from the solar energy system. This method is particularly advantageous for larger installations or systems where fluid must be moved across long distances or elevation changes. The increased control and flexibility provided by pumps allow for more robust drainage processes, helping to ensure that systems can be emptied more thoroughly and swiftly. However, this method does come with higher energy costs and potential maintenance concerns related to pump functionality.

Selecting the most appropriate method will largely depend on the specific characteristics of the solar energy installation, including size, layout, and fluid types used. A comprehensive assessment is critical before deciding on a draining strategy.

3. IMPLEMENTING SAFETY PRECAUTIONS

When draining circulating fluid from solar energy systems, implementing proper safety precautions cannot be underestimated, as a myriad of risks can arise during this process. The handling of fluids, particularly those that are heated or under pressure, necessitates a careful approach to safeguard personnel and property.

First and foremost, personal protective equipment (PPE) is essential. This may include gloves, goggles, and protective clothing to prevent skin burns or eye injuries from splashes of hot fluid. Moreover, ensuring that all personnel involved in the draining process are trained and aware of the potential hazards can significantly minimize risk.

Additionally, the working environment must be evaluated for safety concerns. This includes ensuring proper ventilation if volatile or hazardous fluids are used, as well as checking for potential slip hazards due to spilled liquids. Setting up barriers or warning signs around the workspace can also help keep unauthorized individuals away from the operation area.

Before initiating the draining process, system pressure should be assessed and safely released if necessary. Having a comprehensive emergency response plan can further alleviate risks, allowing for quick action in case of accidental spills or equipment failure. A proactive approach to safety not only protects individuals but also enhances the reliability of the solar energy system during maintenance phases.

4. REGULAR MAINTENANCE PRACTICES

Routine maintenance practices for solar energy systems play a critical role in ensuring both optimal performance and ease of fluid drainage when required. These practices can include regular inspections, cleaning, and system checks to avoid stagnation and degradation of circulating fluids.

Conducting regular inspections is crucial. This enables technicians to identify any potential leaks or weaknesses in the system before they escalate into more significant issues. Identifying and addressing such problems early can ensure that the system functions efficiently and reduces the likelihood of needing complicated drainage procedures due to failures.

Another essential aspect of maintenance is cleaning the system, which can involve flushing out the circulating fluid periodically to remove debris, sediment, or contaminants. This not only helps in maintaining the thermal efficiency of the system but also ensures that the draining process is as smooth as possible when it is eventually required.

In addition, keeping meticulous records of maintenance activities can facilitate long-term system health. A well-documented history allows technicians to look for patterns or recurring issues, tailoring maintenance schedules according to the specific needs of the installation. Implementing these regular upkeep practices contributes significantly to a solar energy system’s usability and longevity.

FREQUENTLY ASKED QUESTIONS

HOW OFTEN SHOULD I DRAIN THE CIRCULATING FLUID IN MY SOLAR ENERGY SYSTEM?

The frequency of draining circulating fluid depends on various factors, including the type of solar energy system, the quality of the circulating fluid, and the operational conditions. It is typically advisable to drain the fluid once every few years. However, if the fluid is exposed to extreme temperatures, contamination, or if there are visible signs of debris accumulation, more frequent draining may be warranted. Regular inspections can help ascertain the condition of the fluid. Additionally, maintenance practices, such as flushing the system, can also significantly enhance the efficiency and prolong the life of the circulating fluid by preventing clogs and sediment buildup. Consulting with professionals to establish a tailored maintenance schedule based on specific operational criteria is beneficial.

WHAT ARE THE SIGNS THAT THE CIRCULATING FLUID NEEDS TO BE DRAINED?

Several indicators suggest that circulating fluid in a solar energy system may require draining. Look out for discoloration or odorous changes, which can indicate contamination. Presence of sludge or sediment within the fluid signifies the need for urgent attention, often requiring immediate flushing and draining to avoid clogs that may disrupt normal functioning. Monitoring for decreases in heating efficiency is another crucial sign; if the system is underperforming or takes longer to heat adequately, it may be due to degraded fluid. Regular visual inspections and operational assessments play an essential role in detecting these signs early, ensuring preemptive maintenance measures can be implemented to maintain optimal system performance.

WHAT TYPES OF FLUIDS ARE USED IN SOLAR ENERGY SYSTEMS?

Solar energy systems utilize various types of fluids, each designed for specific operational requirements. The most common fluid used is water, which is ideal in freezing climates but may require additional additives such as antifreeze to prevent freezing in cooler temperatures. Alternatively, specialized heat transfer fluids, such as propylene glycol or ethylene glycol mixtures, are often preferred in regions prone to frost, as they provide superior thermal performance and lower freezing point properties compared to plain water. Other heat transfer mediums might include thermal oils for high-temperature applications. The selection of fluid directly affects efficiency, heat transfer rates, and overall system longevity, thus necessitating careful consideration during installation.

The process of draining circulating fluid in solar energy systems is a complex yet essential procedure for maintaining efficiency and safety. Each component of this undertaking—understanding fluid dynamics, selecting suitable drainage methods, implementing safety precautions, and adhering to regular maintenance practices—plays a vital role in ensuring that solar energy systems operate at peak performance. By grasping these fundamental aspects, technicians and operators can make informed decisions that not only promote the longevity of the systems but also contribute to sustainable energy usage. Notably, the fluid dynamics underpinning the entire system must be understood to effectively manage circulation and drainage; they inform the approach to maintenance and operational efficiency. Properly selecting drainage methods impacts both energy costs and fluid management, highlighting the importance of tailored strategies for each specific installation. Solving safety concerns is paramount, as it protects personnel and equipment during the drainage process, while regular maintenance encourages a proactive stance, identifying issues before they necessitate complex interventions. Thus, a comprehensive understanding and strategic application of all these elements lead to successful management of circulating fluids in solar energy systems, maximizing their benefits in our collective pursuit of sustainable energy solutions.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-drain-the-circulating-fluid-in-solar-energy/