How to disassemble solar cells

1. Solar cell disassembly involves a series of steps to safely and effectively separate individual components, including a thorough understanding of the solar cell’s structure and materials. 2. Appropriate tools and protective gear must be utilized to ensure safety throughout the process. 3. The materials recovered from disassembly can be reused or recycled, contributing to environmental sustainability. 4. Specific techniques and methods will vary based on the type and design of the solar cell.

1. UNDERSTANDING SOLAR CELLS

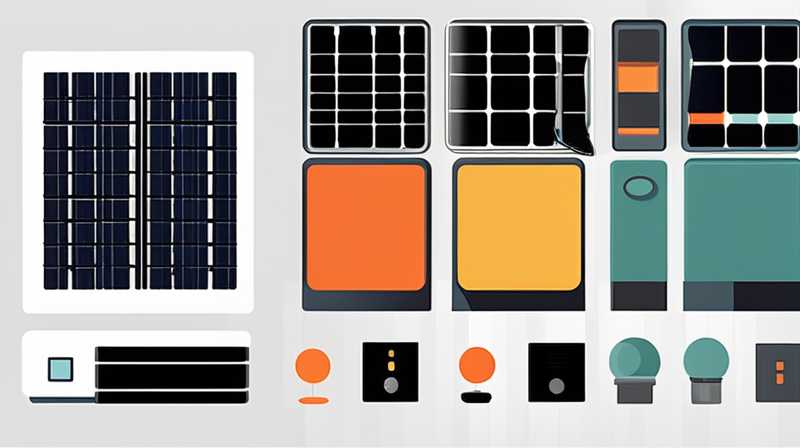

Solar cells, also known as photovoltaic cells, consist of layers of semiconductor materials that convert sunlight into electricity. Their structure typically consists of a silicon wafer, conductive metal contacts, and a protective layer to shield against environmental damage. Understanding how these components work together is essential for effective disassembly.

The most commonly used materials in solar cells include crystalline silicon and thin-film technologies. Both types have their peculiarities in terms of assembly and disassembly. For example, crystalline silicon cells are usually made from a single silicon crystal or multiple crystals, while thin-film cells utilize layers of materials deposited on surfaces. Each type requires different techniques, tools, and safety measures for disassembly.

2. PREPARING FOR DISASSEMBLY

Before embarking on a disassembly project, it’s crucial to gather all necessary equipment. Essential tools typically include safety goggles, gloves, a multimeter, screwdrivers, and a heat source. Additionally, a clean workspace is vital for keeping components organized and preventing contamination.

Personal protective equipment is paramount. Solar cells may have hazardous materials, including cadmium or lead, especially in certain types of thin-film cells. Therefore, wearing gloves and goggles is crucial throughout the process to protect against harmful substances. Planning the disassembly sequence beforehand can streamline the process and minimize the risk of damage to components.

3. DISASSEMBLING CRYSTALLINE SILICON CELLS

Crystalline silicon cells generally have a more straightforward disassembly procedure compared to thin-film counterparts. Begin removing any frames or back sheets using a screwdriver or appropriate tool. It’s important to handle these components carefully to avoid damaging the silicon wafer.

After the outer structure is removed, the next step involves careful extraction of the silicon wafer. Use a multimeter to check for any residual electricity in the cell before handling. The wafer can usually be separated from the conductive contacts using a gentle heating method to soften any adhesive material. Care must be taken not to apply excessive heat, which can compromise the integrity of the silicon.

4. DISASSEMBLING THIN-FILM SOLAR CELLS

Thin-film solar cells present a unique challenge due to their layered structure. Disassembly often requires chemical solvents or heat to separate layers effectively. Start by removing any frames or protective barriers to access the cell layers underneath.

Employing a heat source carefully allows for the loosening of adhesive materials used in construction. It’s vital to maintain consistent temperatures, as overheating can damage the sensitive materials. Once the layers are separated, safely store each component for potential recycling or reuse. Being meticulous during this process is critical for maximizing recovery while minimizing waste.

5. RECOVERY AND RECYCLING OF MATERIALS

Once disassembled, various materials can be recovered. Silicon wafers can be repurposed for new solar cells, while conductive metals may be recycled for different applications. Additional materials, such as glass and plastics from the protective layers, can also be repurposed or recycled to reduce environmental impact.

Recycling solar cells is becoming increasingly important due to the growing volume of solar technology being used worldwide. From an environmental perspective, there are both financial and ecological benefits to this recycling process. It reduces waste in landfills and conserves resources by allowing materials to be reused multiple times, contributing to a circular economy.

6. SAFETY CONSIDERATIONS

Throughout the disassembly journey, safety should be paramount. Solar cells may contain hazardous materials that pose health risks if mishandled. Knowing how to identify and manage these risks is essential for anyone undertaking this task.

Proper ventilation is crucial during the disassembly process, especially when using heat sources or solvents. Ensure the workspace is well-ventilated to minimize exposure to fumes that may be harmful. In addition to personal protective equipment, understanding the chemistry and properties of materials inside solar cells can help mitigate risks and promote a safer environment.

FREQUENTLY ASKED QUESTIONS

HOW CAN I SAFELY DISASSEMBLE SOLAR CELLS?

To safely disassemble solar cells, it is imperative first to wear appropriate personal protective equipment, including gloves and goggles. Establishing a clean, organized workspace aids in keeping track of components. Before starting, disconnect the cells from any power source to avoid electrical shock. Use specialized tools designed for handling delicate materials, and avoid excessive force, as both crystalline silicon and thin-film cells can be fragile. Employ proper disassembly techniques, such as heating to soften adhesive layers or using specific solvents for thin-film cells. Always dispose of hazardous materials per local regulations to protect both health and environment.

WHAT TOOLS ARE REQUIRED FOR DISASSEMBLING SOLAR CELLS?

Disassembling solar cells necessitates a variety of tools to ensure both efficiency and safety. Essential tools include safety goggles, gloves, a multimeter, an array of screwdrivers, and a heat source for softening adhesive materials. Specialty tools designed for precision work may also be beneficial, particularly when handling sensitive components like silicon wafers. Adequate storage containers for sorting small parts and labels for identifying materials can further streamline the assembly and recycling process.

CAN RECOVERED MATERIALS FROM DISASSEMBLED SOLAR CELLS BE RECYCLED?

Yes, materials recovered from disassembled solar cells can be recycled and repurposed. Silicon wafers, which are the core component of most solar cells, can be refurbished and reused in new solar technologies. Conductive metals, typically aluminum or silver, may be recycled into other products, significantly reducing waste. Materials like glass and plastics from protective covers can also be recycled, fostering a sustainable approach through resource conservation. Engaging in recycling and recovery endeavors not only contributes to environmental protection but also encourages a circular economy within the energy sector.

7. IMPORTANCE OF SOLAR CELL DISASSEMBLY FOR FUTURE SUSTAINABILITY

Engaging in solar cell disassembly not only allows for material recovery but also enhances the sustainability narrative surrounding renewable energy technologies. The growing dependency on solar energy means that the end-of-life management of these systems is becoming increasingly vital. As solar technologies evolve, so does the need for responsible disposal and recycling practices. By understanding the components of solar cells and how to disassemble them responsibly, individuals and organizations can contribute to sustainability goals while benefiting economically.

The disassembly process can greatly reduce environmental impact. Traditional waste management practices often lead to significant landfill contributions, which can be mitigated through recycling. By repurposing materials, not only is waste minimized, but the demand for raw materials in new solar technologies also decreases, promoting resource conservation. Additionally, enhancing knowledge surrounding the disassembly of solar technologies can lead to more widespread adoption of recycling initiatives, thereby fostering a culture of sustainability.

As awareness and technology advance, the future of solar cell disassembly appears bright with potential innovations aimed at enhancing efficiency, safety, and profitability. Incorporating practices such as modular design in new solar cell products could simplify future disassembly processes, making recycling even easier and more effective. Furthermore, educational programs focusing on both the installation and disassembly of solar technology are essential for training a workforce capable of navigating the emerging complexities of renewable energy solutions.

By actively participating in solar cell disassembly and advocating for responsible practices, one can contribute significantly toward a greener planet, turning challenges associated with renewable energy waste into opportunities for innovation, recovery, and sustainability. The comprehensive understanding gained through this process aids not just individual practitioners but can potentially drive policy changes and industry standards, ensuring a more sustainable future for solar energy and its technological advances.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-disassemble-solar-cells/