To reconnect a broken solar power lead wire, 1. assess the damage thoroughly, 2. strip the insulation carefully, 3. twist the wires securely, 4. insulate the joint properly. Begin by evaluating the specific area of the lead wire that has been compromised. Using wire strippers, remove a portion of the insulation from both sides of the broken wire, ensuring not to cut into the copper strands. After exposing the ends, align the wires side by side, twist them together tightly to create a secure connection, and finish by wrapping the joint with electrical tape or heat-shrink tubing. This method will ensure optimal conductivity and protection against potential environmental damage.

1. UNDERSTANDING SOLAR POWER LEAD WIRE

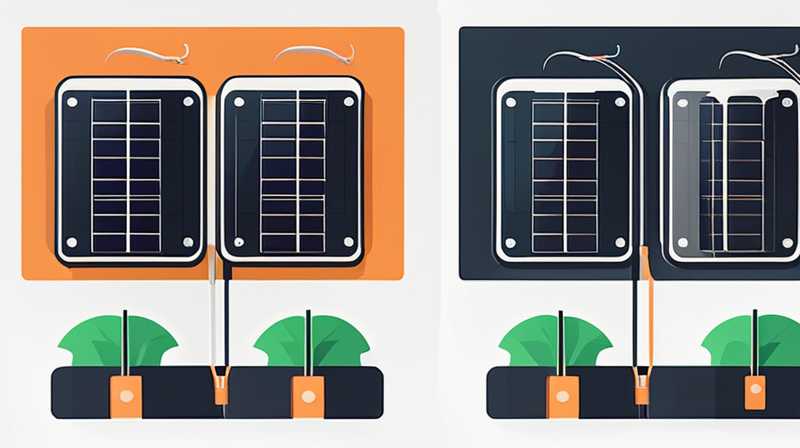

Solar power systems rely extensively on various components for efficient energy conversion and distribution, one of which is the lead wire. Understanding its function is crucial for anyone involved in solar energy, whether you are a DIY enthusiast or a professional installer. Lead wires are responsible for transferring the electrical current generated by solar panels to the inverter and, subsequently, to the electrical grid or storage system. They are typically made of copper due to its excellent conductivity properties.

Lead wires can sometimes experience issues, such as breaks or damages, due to external factors like environmental conditions, wear and tear, or even accidents during installation. This highlights the importance of understanding the anatomy of these wires, which often include the copper conductor surrounded by insulation. Awareness of the different specifications, including gauge size and insulation type, is essential, as using inappropriate replacements can lead to inefficiencies or hazards in the system.

2. IDENTIFYING THE PROBLEM

Before attempting any repairs, it is imperative to identify the precise nature and extent of the damage to the lead wire. Look for signs such as fraying, cuts, or areas where the insulation has degraded significantly. It is also important to consider environmental factors that may have contributed to the wire breaking, like frequent exposure to extreme temperatures or poor installation practices.

Once visual inspections have been completed, using a multimeter to test continuity can provide additional confirmation of the wire’s functionality. A multimeter will allow you to accurately determine whether the electrical current is flowing through the lead wire. If there is no continuity, it indicates a greater issue that might require a more in-depth examination or replacement of the wire altogether. Thus, a thorough evaluation is crucial before proceeding.

3. TOOLS REQUIRED FOR REPAIR

Gathering the correct tools plays a vital role in the repair process. Using proper equipment ensures a seamless connection as well as safety for both the technician and the solar system. A wire stripper is necessary for removing insulation without damaging the conductor. It allows for precise cuts, which is essential in maintaining the integrity of the copper strands.

In addition to wire strippers, you will need a pair of pliers for twisting the wires together firmly; this will ensure a robust electrical connection. A multimeter is also fundamental, as mentioned earlier, for testing voltage and continuity. Finally, insulating materials such as electrical tape or heat shrink tubing will protect the connection from environmental hazards. Ensuring you have all these tools at hand will make the process quicker and more efficient.

4. REPAIRING THE BROKEN WIRE

Once you’ve gathered the necessary tools and identified the problem, the next step involves repairing the broken lead wire. Begin by using wire strippers to carefully remove a section of insulation from both ends of the broken wire, typically around half an inch depending on the wire gauge. Take care to strip only the insulation and not the copper strands beneath.

After the insulation is stripped, align the exposed copper ends side by side, ensuring they are in contact. Utilize pliers to twist the wires together tightly; this allows for maximum surface area contact, which is crucial for conducting electricity efficiently. The twist should be secure to prevent any disconnection that may arise due to vibrations or movement. Following this, it will be essential to insulate the exposed copper to prevent short circuits or exposure to moisture.

5. INSULATION AND PROTECTION OF THE REPAIR

Insulating the joint of the wire is equally important in ensuring a successful repair. The exposed copper, if left unprotected, can corrode over time due to environmental factors such as humidity or rain, potentially leading to further failures. To properly insulate the connection, wrap electrical tape tightly around the twisted area. Make sure the tape covers both the wires and some of the surrounding insulation to provide an effective seal.

Alternatively, heat shrink tubing can be used for added durability. If using this method, slide the tubing over the twisted joint and use a heat gun to shrink it down to fit snugly around the repaired area. This not only creates an airtight seal but also provides a robust layer of protection against physical damage. Whichever method is chosen, ensuring a high-quality insulation job will significantly extend the longevity of the repair.

6. TESTING THE REPAIR

Testing the repair is a critical step that should never be overlooked. After insulation has been applied, it is advisable to conduct a thorough check to ensure the connection is secure. Using a multimeter, test the continuity once more. Set the multimeter to the appropriate setting and touch the probes to either end of the connection. If the multimeter indicates a complete circuit, it confirms that the repair is successful and energy can flow freely along the repaired lead wire.

Furthermore, perform a voltage check under load conditions, especially if the lead wire is part of a larger array. This will ensure that the connection continues to work correctly when the solar panel system is operational. Keeping a record of the testing results can also be beneficial, especially for maintaining an inventory of repairs made on the solar power system.

7. PREVENTING FUTURE DAMAGES

While fixing a broken lead wire is important, preventive measures can significantly reduce the likelihood of similar issues occurring in the future. It is critical to assess the installation environment and ensure that wires are correctly secured, especially in areas subject to physical stress or extreme weather conditions. Incorporating proper cable management tools, like conduits or trays, can minimize external damage.

Additionally, periodic inspections and maintenance can catch potential problems before they escalate. Regular checks of all wiring for signs of wear, corrosion, or stress can help to ensure that the solar power system operates optimally. Introducing these practices not only extends the lifespan of the solar components but also saves time and resources in the long run due to reduced repair needs.

FAQs

WHAT CAUSES SOLAR POWER LEAD WIRE DAMAGE?

Solar power lead wire damage can occur due to various factors, including environmental conditions, improper installation, and age-related wear. Extreme weather, such as heat, rain, or snow, can lead to insulation degradation. Furthermore, physical disturbances, such as heavy objects resting on wires or vibrations from nearby equipment, can contribute to wear. Over time, exposure to UV radiation can weaken the insulation, creating a higher susceptibility to breaks. Lastly, using inappropriate wire gauges or materials during installation can set the stage for future failures. Overall, understanding these causes is essential for implementing preventive strategies effectively.

HOW OFTEN SHOULD SOLAR POWER WIRING BE INSPECTED?

Inspecting solar power wiring should be done at least annually to ensure optimal performance. Regular inspections allow homeowners or technicians to identify any wear and tear that might have developed over time. Additionally, checks should be made after severe weather events, such as storms or heavy snowfall, as these conditions can adversely affect the wiring. It is imperative to closely examine the insulation for cracks or fraying and check for secure connections and proper fastening. Regular maintenance increases the solar power system’s longevity and efficiency, preventing small issues from becoming larger, costlier repairs in the future.

CAN A BROKEN SOLAR POWER WIRE BE REPLACED INSTEAD OF REPAIRED?

Yes, a broken solar power wire can be replaced entirely if the damage is extensive or if multiple repairs have been needed in the past. Replacement often proves to be a more secure long-term solution, particularly in cases where the wiring has suffered significant wear or degradation, particularly in older systems. If opting for a replacement, it is crucial to ensure that the new wires meet the specifications set forth by the solar system manufacturer. This will guarantee compatibility and safety. While repairs may serve as a quick fix, replacement often improves system efficiency and reliability significantly.

Repairing a broken solar power lead wire is an essential skill for anyone involved with renewable energy systems. By understanding the damage, gathering the right tools, executing a proper repair, ensuring insulation, and conducting effective testing, you can maintain the reliable functioning of your solar installations. Preventive measures can mitigate future issues, allowing for long-lasting benefits in both performance and energy savings. Mastery of these fundamental actions contributes greatly to personal empowerment with solar technology, promoting sustainability and independence.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-connect-the-solar-power-lead-wire-if-it-is-broken/