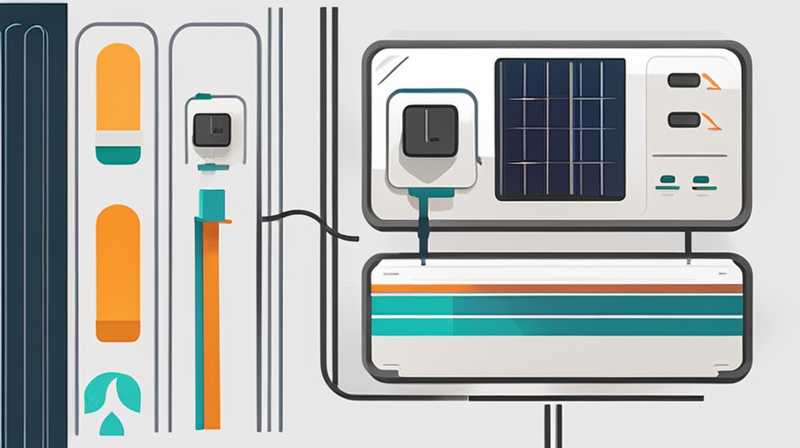

To connect the solar inverter box line, follow these steps: 1. Gather required equipment, 2. Disconnect power supply, 3. Connect AC and DC lines, 4. Check connections for safety, 5. Turn on the inverter. Each step ensures secure and efficient connectivity of the solar inverter, vital for optimal solar system performance.

1. INTRODUCTION

The integration of solar energy into residential and commercial sectors has witnessed significant acceleration in recent years. A crucial component of any solar energy system is the inverter, often referred to as the heart of the solar setup. The inverter transforms the direct current (DC) generated by solar panels into alternating current (AC), which is essential for powering home appliances and feeding power back into the grid. Proper connection of the solar inverter box line is paramount for ensuring the system operates seamlessly and efficiently.

This process is not merely a technical task; it entails an understanding of electrical principles, safety protocols, and communication between various components of the solar system. An expertly connected inverter facilitates maximum energy conversion and minimizes operational risks. Delving into the specifics of connecting a solar inverter box line involves examining the necessary tools, understanding electrical codes, and adhering to safety precautions.

2. PREPARING FOR CONNECTION

A. GATHERING ESSENTIAL EQUIPMENT

Before embarking on the task of connecting the solar inverter box line, procuring the right tools and materials is imperative. Standard tools typically include wire strippers, screwdrivers, a multimeter for measuring voltage, and appropriate connection hardware. Furthermore, insulated gloves and safety goggles should be considered mandatory to protect against potential electrical hazards. Ensuring that all equipment is readily available can streamline the connection process and eliminate any unnecessary interruptions.

Alongside tools, the selection of appropriate cables is critical. The gauge and type of cable used must align with the specifications outlined in the inverter’s manual. Using cables with insufficient ratings can lead to overheating and potential circuit failure. Consulting local electrical codes may offer insights into regulatory requirements surrounding cable selection, ensuring compliance while promoting safety.

B. UNDERSTANDING ELECTRICAL CODES AND REGULATIONS

Each locality possesses regulations governing electrical installations, particularly for renewable energy systems. Familiarizing oneself with these codes not only promotes safety but also guarantees that the installation meets municipal standards. Common regulations involve the correct sizing of wires, adherence to grounding protocols, and ensuring that the installation is visible for inspection by qualified personnel.

Feel free to research local codes or consult a professional electrician specializing in solar installations. Regulations may encompass specific requirements concerning connecting solar inverters to the grid, especially in regions where renewable energy systems receive incentives or rebates. Complying with these standards is a prudent step toward avoiding costly rework or potential legal ramifications.

3. DISCONNECTING THE POWER SUPPLY

A. ENSURING SAFETY FIRST

Before initiating any wiring tasks, disconnecting the main power supply to the solar system is paramount. This action prevents accidents resulting from unexpected surges of electricity. Identifying the main breaker and turning it off can eliminate risks associated with electrical shock and equipment damage. Using lockout tags to visually signify that maintenance is underway can further enhance safety and prevent unauthorized power return.

Awareness of the inverter’s specific shutoff procedure is essential, as many models feature their safety switches or circuit breakers. Consulting the user manual can guide the proper method for safely deactivating the solar inverter. Always communicate with other household members to ensure everyone is aware of the ongoing work and understands that power is disconnected.

B. CHECKING VOLTAGE WITH A MULTIMETER

Once the power supply is disconnected, it is prudent to ascertain that the inverter and connected circuitry are genuinely devoid of voltage before proceeding to connection tasks. A multimeter provides an efficient means to verify voltage levels. Testing both AC and DC sides of the inverter can guarantee that no residual power remains. Familiarity with appropriate multimeter usage—including settings for measuring different types of currents—is essential for accurate readings.

If voltage is detected, it’s critical to address the issue before proceeding, as this could signify a fault in the solar energy system or mistaken wiring connections elsewhere that require correction. A well-conducted voltage check ensures that the technician can work confidently without the concern of unexpected surges.

4. CONNECTING THE AC AND DC LINES

A. STARTING WITH DC CONNECTIONS

With power securely disconnected and verified, the next phase involves establishing connections for the DC line, where components from the solar panels link to the inverter. Identifying the positive and negative terminals is crucial, as improper connections can damage both the inverter and the solar panels. Color coding is typically utilized, with red indicating positive and black denoting negative. Ensuring that cables are free from fraying or damage before connecting them can help achieve a quality connection that promotes efficient performance.

Follow the manufacturer’s instructions regarding wire length and connections, as certain models might call for specific configurations. Utilizing connectors—such as MC4 connectors for solar panels—ensures that the connection remains secure. When inserting cables into terminals, it’s vital to tighten connections adequately to prevent unwanted loosening and resulting voltage drop.

B. SECURING AC CONNECTIONS

Following the successful establishment of the DC line, attention must shift towards connecting the AC line from the inverter to the household distribution box or grid. Understanding the inverter’s output configuration is essential; typically, this will involve connecting live, neutral, and ground wires correctly. It is highly advisable to consult the inverter’s user manual for specific wiring configurations that align with local electrical standards.

Safety remains a paramount concern, hence the necessity of using a secondary grounding wire and appropriate circuit breakers in this section of the connection process. Appropriate placement of circuit breakers can facilitate the safe disconnection of power in emergency situations or during maintenance. Ensuring these connections are insulated properly can prevent short circuits that could compromise system safety and efficiency.

5. CHECKING CONNECTIONS FOR SAFETY

A. PERFORMING A THOROUGH INSPECTION

Once the connections are securely made, an exhaustive check of all wiring and terminals is warranted. This phase should encompass ensuring that no wires are pinched, overly bent, or exposed, as such conditions can lead to damage or electrical hazards over time. Proper insulation and cable management are also crucial components of this inspection, as they eliminate the risk of interference or accidental disconnection.

After verifying tightness and insulation of connections, a visual inspection of the workspace is prudent. Ensuring that tools are removed and that the area is tidy minimizes the potential for accidents during the energy restoration phase. An organized workspace may enhance focus and streamline the operational process, anticipating any unforeseen complications as the system is reactivated.

B. UTILIZING MULTIMETER FOR ADDITIONAL SAFETY

Prior to switching the power back on, employing a multimeter once more in this stage can add an additional layer of scrutiny. Measuring continuity in the connections, particularly in the DC circuit, helps assure that connections are solid and functional. This test provides an essential safety net prior to energizing the system, ensuring that everything is functional.

At this stage, it is also wise to review the inverter’s indicators. Many models will provide diagnostic information or status lights that may indicate proper setup. Familiarizing oneself with these indicators can help identify any immediate issues once the power is restored.

6. TURNING ON THE INVERTER

A. REACTIVATING THE MAIN POWER

The moment of truth arrives when reconnecting the main power supply and switching on the inverter. Turning the main breaker back on should be performed carefully, observing any potential irregular indicators or sounds from the inverter. These observations can help determine whether the connections have been successful or if further diagnostic methods are needed.

While some inverters will auto-start once power resumes, others may require manual intervention. Be prepared to engage with the inverter’s interface to select settings conducive to optimal performance in accordance with power needs and local conditions. Following manufacturer guidelines during this reactivation process eliminates common pitfalls and enhances overall system reliability.

B. MONITORING SYSTEM PERFORMANCE

Upon successfully turning the inverter on, monitoring its performance is essential. Evaluating the inverter’s display can provide insights into operational metrics, including power output and efficiency. During the initial hours, it’s advisable to observe for irregularities, as unresolved connection issues may manifest as voltage spikes or other anomalous behavior.

It’s beneficial to document system performance, noting factors such as weather conditions, energy consumption, and the inverter’s efficiency over time. Establishing a baseline performance metric will contribute to identifying patterns that may signal potential issues or opportunities for system optimization in the future. Routine monitoring not only enhances long-term performance but also serves as a proactive approach to maintenance.

7. MAINTAINING A SAFE AND EFFICIENT SYSTEM

A. SCHEDULED MAINTENANCE

Consistency in safeguarding solar energy system efficiency is pivotal. Conducting periodic inspections assures ongoing safety and effectiveness of connections. Regular checks should encompass all aspects: inverter settings, cable insulation, and the state of the solar panels themselves.

Should alterations to the electrical supply occur, consulting with a licensed electrician for adjustments can safeguard against potential problems in the long run. Keeping detailed records of maintenance activities, including adjustments and findings, can help spot trends or recurring issues, promoting informed decision-making regarding system administration.

B. KEEPING UP WITH TECHNOLOGICAL ADVANCEMENTS

The field of solar technology is continuously evolving, with enhancements improving efficiency and integration capabilities regularly entering the market. Staying current with technological developments can empower users to maximize their solar systems. Technologies such as battery storage and smart inverters can introduce new dimensions to solar energy usage, providing enhanced control over energy consumption and efficiency.

Individuals should consider engaging with educational resources, attending workshops, or consulting with solar experts to better understand how innovations can be incorporated into existing systems. Continuous learning can foster empowerment and promote more effective energy management strategies for the entire household.

FREQUENTLY ASKED QUESTIONS

HOW DOES A SOLAR INVERTER WORK?

A solar inverter converts the direct current (DC) generated by solar panels into alternating current (AC) suitable for consumer use. The inverter monitors the output from the solar panels, adjusting the energy conversion process to maximize efficiency while ensuring safe operation. It also handles the synchronization with the electrical grid, allowing surplus power to be sent back to the grid when production exceeds consumption, or pulling energy from the grid when necessary. By regulating voltage levels and performing diagnostics, the inverter plays a pivotal role in optimizing the solar energy system’s performance ensuring grids remain stable.

DO I NEED A PROFESSIONAL TO CONNECT A SOLAR INVERTER?

While some individuals might possess the technical know-how, hiring a professional can often ensure a higher level of safety and compliance with regulations. Solar inverters comprise intricacies that require advanced knowledge of electrical systems and proper integration with the grid. Professionals are familiar with local codes, safety protocols, and best practices, which may significantly reduce the chances of potential issues down the line. Consulting with an experienced technician can also facilitate the selection of suitable equipment and tools tailored to specific system requirements for optimal performance.

HOW CAN I TROUBLESHOOT MY SOLAR INVERTER?

Troubleshooting a solar inverter involves a systematic approach, closely examining all connections and settings. Begin by checking for errors displayed on the inverter’s interface, noting any specific diagnostics provided. Ensure all electrical connections are secure, insulated, and free of damage. Also, review settings to confirm they are properly configured for energy use and monitoring. If problems persist, consulting the user manual or seeking advice from professionals can expedite identifying solutions and resolving inefficiencies that may hinder the system’s overall performance.

Assessing and connecting the solar inverter box line is a critical and multifaceted task that promotes the safety and efficacy of a solar energy system. The process begins with an interrogation of requirements that encompass a profound understanding of the prerequisites, regulations, and equipment necessary for efficient operation. Through stringent safety checks and effective connection methodologies, one can achieve seamless energy transformation and integration into both residential and grid systems. The importance of adhering to local electrical codes throughout this journey cannot be overstated, encompassing essential milestones from gathering equipment and ensuring secure electrical isolation to activating the inverter and optimizing system performance. Further, regular monitoring and embracing technological advancements play significant roles in propelling the solar energy revolution. By committing to a strategic approach in connecting the inverter, users can enhance their energy self-sufficiency while contributing to a sustainable future. Engaging with professionals can bolster this process significantly, ensuring safety and compliance while promoting efficiency and satisfaction in what is becoming an integral aspect of modern energy solutions.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-connect-the-solar-inverter-box-line/