Connecting solar tubes with motors involves a series of precise steps and considerations to ensure efficient energy harnessing and functionality. 1. Understanding the equipment needed is essential, 2. Proper installation techniques significantly enhance performance, 3. Aligning the solar tubes optimally maximizes sunlight exposure, 4. Maintenance is crucial for long-term efficacy. By delving deeper into understanding how these components work harmoniously, one can harness solar energy more effectively.

1. UNDERSTANDING SOLAR TUBES AND MOTORS

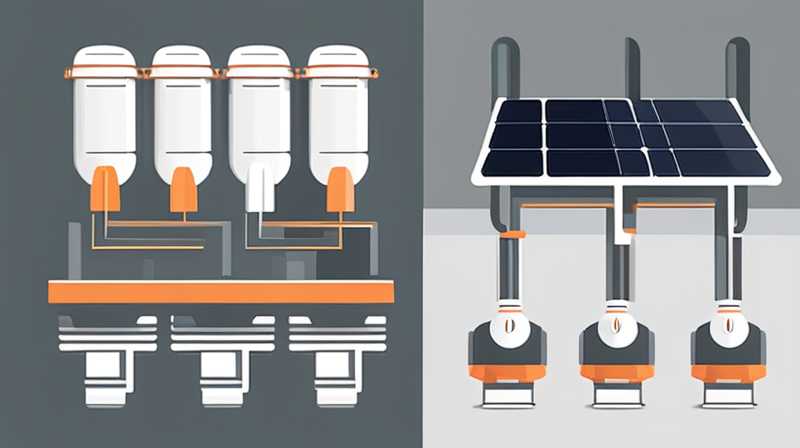

Solar tubes, often referred to as solar tubes or solar collectors, are an innovative way to gather solar energy. They operate by capturing sunlight and converting it into heat, which can then be utilized for various applications, including heating water, spaces, or powering motors directly. Motors in this context typically refer to electric motors that can be driven by the energy collected through the solar tubes. A thorough comprehension of both devices is paramount, as each component’s functionality affects the overall system’s efficiency.

When selecting solar tubes, specific factors must be evaluated, including thermal performance, efficiency ratings, and installation requirements. Each type of solar tube has unique characteristics, such as the material used for the reflective surface or the insulation capability. The effectiveness of solar tubes is largely determined by the angle of sunlight incidence, which fluctuates throughout the day and across seasons. Hence, understanding the geographical and environmental context is essential for effective selection.

On the motor side, selecting the appropriate type is also critically important. Depending on the intended application, whether it’s a high-torque motor for heavy usage or a smaller motor for lighter tasks, the specifications will differ. An ideal motor should not only match the energy output of the solar tubes but also possess features that allow for optimal efficiency. Consideration should be given to power ratings, voltage, speed, and the type of load that the motor will drive.

2. INSTALLATION TECHNIQUES

The installation of solar tubes connected to motors demands a meticulous approach that ensures all components work in unison. Precise alignment and secure fittings are paramount to avoid underperformance. The placement of solar tubes is instrumental; they should be positioned at an appropriate angle to maximize sunlight exposure during peak hours. Depending on the geographical location, a south-facing orientation is generally ideal for optimal sun capture.

Furthermore, the structural integrity of the installation site influences the effectiveness of solar tube setups. It is vital to ensure that the mounting brackets and supports are robust enough to withstand environmental elements such as wind or rain. As ensuring the longevity and efficiency of the system is critical, implementing a quality assurance protocol during installation is advisable. Such protocols may include verifying the tightness of connections and checking for potential obstructions that could cast shadows on the solar tubes.

Once the solar tubes are securely mounted, the next step involves connecting them to the motors. This connection typically involves wiring that must be installed properly to ensure efficient power transfer. Electrical conduits should be weatherproof to protect against potential damage from weather conditions. Thermal and electrical insulation is also essential in preventing energy loss and ensuring the longevity of the components.

3. OPTIMIZING ALIGNMENT

Maximizing the efficiency of solar tubes connected with motors rests significantly on their alignment. Aligning solar tubes with the sun’s trajectory ensures optimal energy collection. This alignment is not a one-time effort; it needs regular adjustments to consider seasonal variations in sun positioning. For areas that experience extreme seasonal shifts, a tracking mount that adjusts throughout the day can significantly increase efficiency.

In tandem with alignment, potential shading from trees, buildings, or other structures can severely diminish the performance of solar tubes. Identifying and removing obstacles is essential. One effective strategy is to conduct a shadow analysis before installation, which helps project the potential shading at different times of the day and year. This can guide the placement of the solar tubes for maximum exposure.

In addition to physical alignment, the settings on the motor should also be calibrated to respond effectively to the varying input from the solar tubes. Employing an energy management system that adjusts motor operations based on available solar energy can optimize performance. These systems can either activate the motor directly from solar energy or store the energy for later use, depending on the design.

4. MAINTENANCE REQUIREMENTS

The efficiency and longevity of the solar tube and motor system are heavily influenced by proper maintenance routines. Regular cleaning and inspection are necessary to ensure that both the solar tubes and motors operate at peak efficiency. Contaminants such as dust, debris, and bird droppings can significantly reduce the absorptive capability of solar tubes. Cleaning should be conducted periodically, especially in areas prone to heavy dust or pollen.

Additionally, inspections should include checking connections for corrosion or wear and evaluating the overall structural integrity of the solar tubes and mounting systems. Machinery parts should be lubricated as necessary, and any signs of malfunction should be addressed immediately. Regular checks ensure that any issues are remedied before they escalate into more significant problems, potentially leading to costly repairs or replacements.

Moreover, keeping up with advancements in solar technology can provide insights into possible upgrades. Utilizing smart monitoring systems may help track performance metrics and diagnose issues in real time, resulting in efficient maintenance strategies. This approach not only keeps the system running smoothly but also maximizes the return on investment.

FREQUENTLY ASKED QUESTIONS

CAN SOLAR TUBES POWER ELECTRIC MOTORS DIRECTLY?

Yes, solar tubes can directly power electric motors, contingent on the output of the solar collection system. The functionality depends on the capacity of the solar tube to generate sufficient energy to meet the motor’s requirements. Typically, smaller motors used for lighter applications may operate directly on the energy collected from solar tubes. For larger, high-demand motors, it may necessitate additional energy storage solutions like batteries to provide a steady supply, especially during non-sunny periods. Solar tubes can convert sunlight into heat, which then can be transformed into mechanical energy through motors. The alignment of solar tubes for optimized energy collection plays a significant role in ensuring that adequate energy is being harnessed.

WHAT MAINTENANCE IS REQUIRED FOR SOLAR TUBE SYSTEMS?

Routine maintenance for solar tube systems primarily entails cleaning and inspecting the tubes themselves as well as the connecting motors and structures. It’s crucial to remove any debris that may impede sunlight collection, as even a small layer of dust can significantly affect efficiency. Checking electrical connections for any signs of wear or corrosion is also essential, as these can lead to energy losses and potential system failures. Additionally, ensuring that the physical mounting remains stable, and free from damage due to environmental factors are key aspects of maintenance. This ongoing diligence not only preserves the operational capacity of solar collectors but also ensures longevity and sustained performance. Overall, proactive measures can prevent unnecessary repair costs over time.

HOW DO I DETERMINE THE RIGHT SIZE OF SOLAR TUBES FOR MY SYSTEM?

Determining the appropriate size for solar tubes in a given system requires evaluating several parameters, including energy requirements, available space, and geographic location for sunlight intensity. The energy needs should be calculated to understand the demand certainly. Next, the area available for installation can limit the size and number of solar tubes; in crowded environments, compact solutions may be necessary. The local climate and the pattern of sunlight exposure can greatly influence the energy efficiency of solar tubes; locations with prolonged sunlight exposure are more suited to larger installations. Additionally, engaging with specialists and using simulation tools can provide tailored insights into system design, ensuring that energy needs are adequately met without unnecessary overspending on excess capacity.

A comprehensive approach to assembling solar tubes with motors is essential for maximizing solar energy utilization. Understanding the intricacies of both components lays a solid foundation for effective installation and optimal performance. The necessity of precise alignment and meticulous maintenance cannot be overstated, as these factors directly impact efficiency and longevity. A forward-thinking strategy that includes monitoring energy performance and keeping up with technological advancements can enhance the operational success of the system. With consistent care, proactive adjustments to align with seasonal changes, and a commitment to maximizing each component’s functionality, solar tube systems have the potential to provide reliable and sustainable energy solutions. Overall, the integration of renewable energy technology not only aids in reducing dependence on fossil fuels but also fosters environmental consciousness, paving the way for a more sustainable future.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-connect-solar-tubes-with-motors/