To select the appropriate lift for a solar pipeline pump, several key factors must be considered. 1. Hydraulic lift requirements differ depending on fluid characteristics, including viscosity and density, as these properties impact the energy needed to move the fluid. 2. The geographical location plays a critical role, as solar intensity varies across regions and affects the efficiency of solar panels. 3. Pump design and material compatibility are essential, ensuring that the pump can withstand the operational environment and the fluids being conveyed. 4. Longevity and maintenance requirements should be assessed, as different pumps have varying durability levels based on technology and materials used, thereby influencing long-term operational costs.

Elaborating on hydraulic lift requirements, the specific system and application dictate the required lift. For instance, applications that involve transporting water from deep wells necessitate a higher lift than surface water extraction. It is also crucial to consider the head loss caused by friction, particularly in long pipeline runs, as this adds to the necessary lift calculations. Knowledge of these requirements is fundamental in selecting a suitable solar pipeline pump capable of maintaining efficiency and performance in the intended application.

1. UNDERSTANDING LIFT IN SOLAR PIPELINE PUMPS

Lift refers explicitly to the height to which a pump can raise a fluid, and in the context of solar pipeline pumps, it is a parameter that determines the pump’s ability to transport fluid effectively from one point to another. The lift is measured in units of vertical height, such as meters or feet, and is crucial for applications such as irrigation, water supply, or drainage.

When contemplating the lift requirements for a solar pipeline pump, it is imperative to recognize that the vertical dimension of the lift directly correlates with the pump’s energy consumption and overall efficiency. Additionally, comprehensive knowledge of system hydraulics contributes to accurate lift calculations. Factors like the specific gravity of the fluid, elevation changes within the pipeline, and friction losses across fittings and pipe lengths must be scrutinized. Understanding these dynamics provides a clear path to making an informed decision regarding the lift required for optimal pump functionality.

Furthermore, different applications demand varying lift specifications. For example, agricultural irrigation systems typically operate at specific lifts designed to optimize crop yield while conserving water. In urban environments, water distribution systems have tailored lift requirements based on modified elevations, which necessitate precise calculations to ensure adequate service delivery.

Selecting the optimal lift for a solar pipeline pump hinges not only on the fluid type and application but also on the existing infrastructure and flow dynamics. Through a meticulous assessment of these factors, one can arrive at a determined lift specification that addresses the operational needs sustainably.

2. EVALUATING SOLAR INTENSITY AND LOCATION

Selecting an apt solar pipeline pump goes beyond just understanding lift; the geographical location plays a quintessential role in determining pump efficiency and system performance. Solar irradiance varies significantly across regions, influencing solar panel output and overall system efficacy. Assessing local climate data can provide insight into how much solar energy can be expected throughout the year.

Solar intensity reflects the amount of solar energy received per unit area and is affected by various factors, including seasonal changes, latitude, and potential obstructions such as trees or buildings. These elements directly influence the production capacity of solar panels, which must be mapped against the pump’s operational demands. A pump requiring substantial energy might perform below expectations in areas with lower solar irradiance unless properly sized and configured.

The location should also determine the type and configuration of solar photovoltaic (PV) modules. For example, if one operates in an area with high sunlight exposure, one can consider a smaller solar panel array, which provides a cost-effective solution for powering the pump while effectively meeting lift needs. Conversely, in regions with less consistent sunlight availability, a larger array might be warranted, requiring careful planning and investment.

Moreover, integrating solar systems with battery storage options can help mitigate fluctuations in solar energy availability throughout the day. A battery allows for energy accumulation during peak sunlight hours, ensuring that the pump can operate even during periods of low irradiance. This combination of solar generation with appropriate energy storage leads to a more reliable supply chain, contributing to the overall efficiency and sustainability of the pumping system.

3. PUMP DESIGN AND MATERIALS

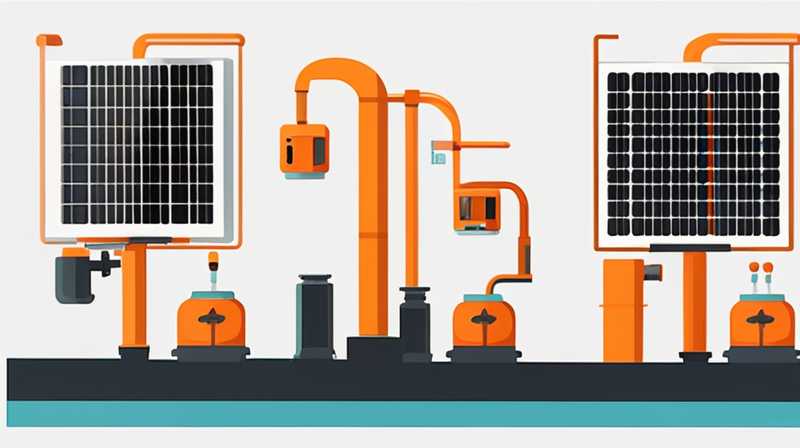

Another salient aspect when selecting a solar pipeline pump is the design and materials used in construction. Different pumps come with various configurations—centrifugal, positive displacement, or submersible—each suited for particular applications and lift requirements. Understanding how pump design contributes to performance and longevity is vital to making an informed selection.

Centrifugal pumps, for example, are widely known for their smooth and continuous flow; however, they may not perform well at higher lifts or with highly viscous fluids. In contrast, positive displacement pumps excel at moving viscous liquids and perform reliably at elevated lifts. Therefore, selecting a design that aligns with specific application requirements ensures effective fluid transfer while optimizing energy consumption.

In addition to design, materials used in pump construction significantly impact durability and resilience. Pumps exposed to corrosive environments or abrasive fluids must be constructed from materials resistant to degradation. Assessing compatibility with specific fluids dictates longevity and maintenance demands; stainless steel or specialized polymers might be necessary for certain applications. Moreover, understanding the wear characteristics of materials against different media being pumped can aid in ensuring that maintenance schedules are pragmatically aligned with operational demands.

Lastly, the choice of technology, whether solar-powered pumps or hybrid systems incorporating conventional energy sources, affects operational strategies. A well-designed pump paired with quality materials can minimize wear and increase service intervals, thereby limiting downtime and costs associated with maintenance and replacement. Ensuring that selected designs and materials are suited for hydraulic conditions enhances overall reliability and efficacy of the pumping system.

4. LONGEVITY AND MAINTENANCE REQUIREMENTS

Longevity is a significant consideration when choosing a solar pipeline pump. Understanding the maintenance requirements linked to various pump technologies can substantially affect total cost of ownership. Some pumps necessitate regular maintenance checks involving fluid inspections, motor assessments, and operational efficiencies to sustain optimal functionality.

Assessing the need for spare parts availability and ease of repair can further guide selection. For instance, while a particular pump design may prove efficient, if spare parts are scarce or expensive, long-term costs can skyrocket. Evaluating the long-term accessibility of service technicians or the pump manufacturer might also factor heavily into choosing a solution.

Bidding for quality materials and reliable designs often translates to reduced replacement frequency, with good warranty offers signaling a manufacturer’s confidence in their product. Regular maintenance, while essential, should also be manageable in terms of time and operational constraints. The ultimate aim is to select a solar pipeline pump that operates efficiently over its life cycle with minimal unscheduled downtimes.

Understanding the operational environment further informs maintenance planning. In harsh climates, potential wear from UV exposure, moisture, and temperature variations must be anticipated when selecting a pump. Implementing a regime that accommodates these factors ensures the continued performance of the pump, including regular checks for integrity and efficiency.

The balance of initial investment against anticipated operational expenses highlights the importance of a long-term perspective when selecting a solar pipeline pump. Not only does longevity matter economically, but it also integrates into operational sustainability frameworks by optimizing resource use, leading to environmentally friendly practices.

5. ANALYZING ENERGY EFFICIENCY

Critical to selecting a viable solar pipeline pump is the calculation of energy efficiency, which reflects the overall performance of the pumping system concerning energy consumption. Energy efficiency is an essential criterion that benefits operational costs while gauging the sustainability of the pumping solution.

Solar pumps vary in terms of system efficiency, and understanding the metrics by which to evaluate them is indispensable. The pump’s hydraulic efficiency, solar conversion efficiency, and system losses need to be addressed to ascertain the effective energy per unit of fluid moved. This comprehensive assessment can highlight whether a particular configuration will meet the expected operational benchmarks over its service life.

Ensuring proper sizing of the pump and solar panel array can significantly improve efficiency. An oversized panel might produce excess energy, leading to wasted potential, whereas undersizing can lead to inadequate operation during periods of peak demand. Using simulation tools or expert recommendations can aid in accurately estimating required capacities based on fluid characteristics, distance, lift, and solar exposure.

Moreover, utilizing monitoring technologies can contribute to improving energy efficiency by providing real-time feedback on pump performance. With advancements in smart technologies, such as IoT-based monitoring systems, operators can gain insights into operational patterns, allowing for swift corrections or adjustments to improve overall system performance.

In essence, measuring and optimizing energy efficiency plays a pivotal role in ensuring that solar pipeline pumps meet both performance requirements and sustainability objectives.

FREQUENTLY ASKED QUESTIONS

WHAT IS THE IMPORTANCE OF LIFT IN SOLAR PIPELINE PUMPS?

Determining the appropriate lift for solar pipeline pumps is essential for several reasons, particularly in fluid dynamics. Lift essentially indicates how high the pump can raise a liquid, dictating its efficiency in various applications like irrigation or industrial process water. A precise understanding of lift is vital because it directly impacts energy expenditure, operational stability, and feasibility across numerous installations. Moreover, deciding on lift correlates with hydraulic head loss due to friction in piping systems, which can necessitate adjustments in pump selection. Ensuring accurate assessment and implementation of lift requirements can optimize pump performance and enhance the sustainability of water management systems.

HOW DOES SOLAR IRRADIANCE AFFECT PUMP PERFORMANCE?

Solar irradiance, the power per unit area received from the sun, plays a critical role in the performance of solar-powered pumps. The efficiency of solar panels depends heavily on the amount of solar energy they can harvest, which in turn affects the energy availability for the pump’s operation. In regions where solar irradiance is high, pumps can operate optimally with smaller solar arrays, effectively lowering initial investments and operational costs. Conversely, in areas with lower solar exposure, larger solar arrays may be required, leading to increased expenses. Proper planning and alignment of pump systems with local solar conditions will ensure optimal system performance, promoting effective water management and resource utilization.

WHAT FACTORS INFLUENCE MAINTENANCE REQUIREMENTS FOR SOLAR PIPELINE PUMPS?

Maintenance requirements for solar pipeline pumps hinge upon several factors encompassing pump design, materials, and environmental conditions. The materials used in constructing the pump influence its susceptibility to wear, corrosion, and environmental stresses. For instance, pumps operating in corrosive atmospheres or handling abrasive fluids may need more frequent checks and replacements. Additionally, the complexity of the pump design can impact maintenance ease; simplified designs may require less recurring effort than intricate assemblies. Finally, the operational environment must be assessed, as extreme weather conditions like high temperatures, humidity, or dust can dictate distinct maintenance strategies to ensure optimal pump life and performance.

In choosing a suitable lift for a solar pipeline pump, it is crucial to integrate various essential factors to ensure optimal design and functionality. Meticulously understanding hydraulic lift requirements, assessing geographical conditions, selecting appropriate pump designs and materials, and planning long-term maintenance strategies are integral to achieving enduring and reliable water transport systems. Each of these factors contributes to a comprehensive understanding of operational dynamics required to enhance efficiency and promote sustainability in water resource management initiatives. The judicious selection process, amid various technological options, also ensures that operational expenditures are minimized while achieving project sustainability objectives.

Notably, incorporating advanced technologies such as remote monitoring and intelligent energy management systems can augment operational performance. By employing such technologies, stakeholders can adapt to changing circumstances or operational needs more adeptly, ensuring that the chosen pump remains efficient throughout its lifespan. By considering these elements collectively, not only can one achieve effective operational performance, but a robust, sustainable system can also be implemented, maximizing return on investment and resource efficiency in critical applications such as irrigation, municipal water supply, or industrial processes. Ultimately, selecting the right lift for a solar pipeline pump marries technical knowledge with practical application, fostering solutions that align with environmental conservation values while addressing practical water needs across diverse settings.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-choose-the-lift-of-solar-pipeline-pump/