To alter the solar insulation fluid in a solar thermal system, several essential steps should be considered diligently. 1. Safety precautions must be prioritized to prevent accidents, 2. Proper drainage and removal of the old fluid is crucial for maintaining system integrity, 3. The selection of an appropriate new fluid is vital to ensure optimal system performance, 4. Finally, regular maintenance checks post-replacement guarantee that everything remains in optimal condition.

While discussing the third point in detail, it’s important to understand that the type of heat transfer fluid can significantly affect efficiency and longevity. For instance, propylene glycol offers excellent corrosion resistance and a lower toxicity rating compared to ethylene glycol, making it a safer choice for applications in residential settings. Understanding the physical properties and compatibility of the new fluid with existing materials is essential before making a decision.

1. UNDERSTANDING SOLAR INSULATION FLUID

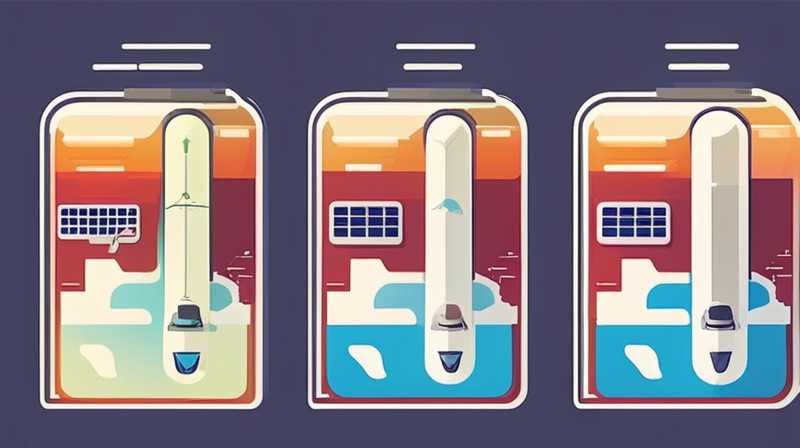

Solar thermal systems rely heavily on heat transfer fluids to capture and transport energy. Insulation fluids are engineered to absorb solar energy efficiently and deliver it to storage tanks or directly to the heating system.

In these systems, solar radiation is captured by panels, heating the fluid within. The heated fluid then circulates through pipes to transfer heat either to a water storage tank or directly to appliances that require heating. Additionally, the choice of insulation fluid affects not only the performance but also the durability and efficiency of the entire system.

1.1. TYPES OF SOLAR INSULATION FLUIDS

A variety of fluids can be used in solar thermal systems, including water, propylene glycol, and ethylene glycol. 1. Water is the most common due to its abundance and high specific heat capacity. However, it can freeze in colder climates, causing potential damage to the system. 2. Propylene glycol is a non-toxic alternative that provides excellent thermal performance and has a lower environmental impact. 3. Ethylene glycol, while effective, poses toxicity risks and is less favored in residential applications.

When selecting a fluid, it is essential to consider regional climate conditions, as freezing temperatures can compromise a system using water or ethylene glycol. Particularly in colder regions, propylene glycol is recommended due to its lower freeze point.

1.2. IMPORTANCE OF REPLACEMENT

Over time, the performance of insulation fluids degrades due to oxidation, contamination, and chemical breakdown. 1. Routine replacement is critical for ensuring consistent energy transfer efficiency. 2. Fluids that are left unchecked may lead to a buildup of sludge or corrosion, significantly impacting the heating system’s performance and longevity.

Regular monitoring of the fluid can indicate when a replacement is needed. Indicators might include changes in color, clarity, or the appearance of particulates.

2. SIGNS THAT YOU NEED TO CHANGE SOLAR INSULATION FLUID

Identifying when to change your insulation fluid is vital to maintaining an efficient solar thermal system. Certain signs may suggest that replacement is necessary.

2.1. OBSERVABLE CHANGES IN FLUID

1. One primary indicator of compromised fluid is a visible change in color. If the fluid is dark or murky, it may have degraded and should be replaced. 2. Additionally, a change in consistency, such as becoming thicker or more viscous, can suggest contamination or odd chemical reactions occurring within the fluid.

When those signs appear, it may be beneficial to inspect the system for potential leaks, kinks, or other issues that may have contributed to the fluid’s degradation.

2.2. PERFORMANCE DEGRADATION

Another critical sign for fluid replacement is a noticeable decrease in system performance. 1. If the solar collectors are producing less heat output than expected, it could be a sign that the fluid’s thermal properties have diminished. 2. Increased energy costs or erratic temperature changes in the hot water could also indicate that the fluid is no longer effectively transferring heat.

If performance issues arise, it is important to conduct a thorough inspection and potentially a fluid change to restore the system’s efficacy.

3. PREPARING FOR FLUID CHANGE

Before proceeding with a fluid change, it is essential to prepare properly to ensure safety and efficiency during the process.

3.1. GATHERING TOOLS AND MATERIALS

1. The first step involves gathering all necessary tools and materials. Ensure you have personal protective equipment, such as gloves and goggles, to safeguard against spills. 2. Required tools might include a wrench for disconnecting pipes, a siphon or pump for draining the old fluid, and containers for storing both old and new fluids.

Moreover, check the compatibility of the new insulation fluid with existing system materials. This attention to detail minimizes the risk of chemical reactions that may compromise the installation.

3.2. DRAINING THE OLD FLUID

1. Begin the process by turning off the solar system and isolating it from the mains. Using the siphon or pump, carefully remove the old insulation fluid from the system. 2. Proper disposal of the used fluid is critical — check local regulations for guidelines on handling and disposing of hazardous materials.

Make sure to collect the fluid in suitable containers and label them if necessary.

4. REPLACING SOLAR INSULATION FLUID

Once the old fluid has been thoroughly drained, the next phase involves introducing the new insulation fluid into the system.

4.1. CHECKING SYSTEM COMPONENTS

1. Before adding the new fluid, it is advisable to inspect all components of the solar thermal system. Check for any signs of wear, leaks, or other issues that might affect the new fluid’s performance. 2. Seals and gaskets should also be inspected for deterioration. Replacing worn-out components before adding the new insulation fluid will augment system reliability.

It’s crucial to address any detected issues at this stage to prevent future complications.

4.2. INTRODUCING NEW FLUID

1. With everything checked and in order, begin pouring the new insulation fluid slowly into the designated ports of the system. 2. While doing this, monitor for any leaks or unexpected reactions. Once filled, it is important to ensure that the system is appropriately vented to eliminate air pockets that could impede performance.

After filling, make sure to follow the manufacturer’s recommendations for the specific fluid used, as different products may have distinct requirements for optimal incorporation.

5. TESTING SYSTEM AFTER REPLACEMENT

Once the new insulation fluid has been successfully introduced, carrying out tests is essential to ensure the system operates correctly.

5.1. INITIAL CHECKS

1. Before turning the system back on, perform an initial check for leaks at all connection points and fittings. Inspect hoses, pipes, and storage tanks for any signs of moisture or dripping. 2. After this evaluation, examine the pressure levels within the system to ensure they fall within the prescribed range suggested by the manufacturer.

These checks help confirm the integrity of the system post-fluid replacement.

5.2. SYSTEM RESTART AND MONITORING

1. Restart the solar thermal system and allow it to operate for a short duration. Monitor the output temperatures and ensure they align with expected values based on the current solar conditions. 2. For the first few days following the fluid change, maintain regular checks to confirm that the system runs smoothly, ensuring timely identification of any anomalies.

Implementing these testing protocols not only enhances operational reliability but also provides peace of mind regarding system integrity.

6. MAINTAINING SOLAR THERMAL SYSTEMS

Ongoing maintenance is essential for extending the lifespan and efficiency of solar thermal systems.

6.1. ROUTINE INSPECTIONS

1. Routine inspections should be scheduled to check fluid levels and system components. Evaluate the appearance of the insulation fluid at regular intervals; look for consistency in color and texture. 2. Keeping a log of inspections helps in noticing trends that may indicate potential problems, allowing for timely interventions.

Maintaining detailed records aids in planning future maintenance and understanding fluid degradation patterns.

6.2. SCHEDULING FLUID REPLACEMENTS

1. Establish a timeline for future fluid replacements based on inspection findings and manufacturer recommendations. 2. Having a proactive approach will prevent unexpected system failures and enhance the system’s overall efficiency.

Being diligent about maintenance ensures that solar thermal systems operate at peak performance levels.

FREQUENTLY ASKED QUESTIONS

WHAT IS SOLAR INSULATION FLUID?

Solar insulation fluid is a critical component used in solar thermal systems to transfer heat from solar collector panels to storage tanks or heating applications. The most commonly used fluids are water, propylene glycol, and ethylene glycol. Each fluid has its unique properties that make it suitable for different environmental conditions. Water is abundant and has a high specific heat capacity, but is vulnerable to freezing in colder climates. Propylene glycol is favored for its non-toxic nature and lower freezing point, while ethylene glycol is effective but carries toxicity risks. The choice of fluid directly impacts energy efficiency, making it a critical decision in system design and maintenance.

HOW OFTEN SHOULD I CHANGE MY SOLAR INSULATION FLUID?

The frequency of fluid replacement depends on various factors including the type of fluid in use, the geographical location, and system design. Typically, it is advisable to check the fluid annually for signs of degradation such as changes in color or consistency. It is suggested that fluids be replaced every 3 to 5 years, depending on the observed conditions. Any noted performance issues, like reduced heating efficiency or increased energy costs, should prompt immediate inspection and potential fluid replacement. Regular monitoring not only helps in maintaining efficiency but also ensures the longevity of the solar thermal system.

CAN I CHANGE SOLAR INSULATION FLUID MYSELF?

Changing solar insulation fluid can be undertaken as a DIY project, but it requires careful preparation and appropriate safety measures. Proper gear should be worn to prevent exposure to chemicals, and all necessary tools should be on hand. Familiarizing oneself with the system manual and understanding the procedures is essential to avoid damage during the process. However, if you are uncomfortable with performing such tasks or lack knowledge about the system components, hiring a professional is advised. DIY changes should ensure all safety protocols are followed to mitigate risks effectively.

In essence, changing the solar insulation fluid is a critical yet manageable task in maintaining solar thermal systems. Prioritizing safety throughout the process leads to successful outcomes. Thoroughly inspecting the system before and after fluid replacement helps catch potential issues early. Additionally, selecting the right fluid tailored to the specific environmental conditions elevates performance and efficiency. Engaging in proactive maintenance extends the viability of the system and fortifies investment in solar energy. Be observant of changes in fluid appearance and performance, responding with timely action to ensure optimal functionality. In doing so, the longevity of your solar thermal system can achieve remarkable efficiency over time, contributing considerably to both energy savings and environmental sustainability. The future of solar energy relies on meticulous care and proper management of these systems, ensuring they remain effective for years to come. Through understanding, diligence, and adherence to best practices, successfully changing the solar insulation fluid becomes a straightforward task that significantly benefits the solar system’s overall performance.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-change-solar-insulation-fluid/