To effectively block solar PPR pipe, 1. ascertain the specific reason for blockage, 2. choose appropriate materials, 3. consider the method of installation, and 4. ensure compliance with local regulations. When discussing the methods for blocking solar PPR pipes, focus on the type of blockage required, whether it’s temporary or permanent, as this dictates the materials and techniques to use. For a temporary blockage, installing removable caps or fittings may suffice, while for permanent solutions, options like sealants and solid caps are more appropriate. Ensure that any obstruction method used does not compromise the integrity of the pipe or the surrounding installation.

UNDERSTANDING SOLAR PPR PIPES

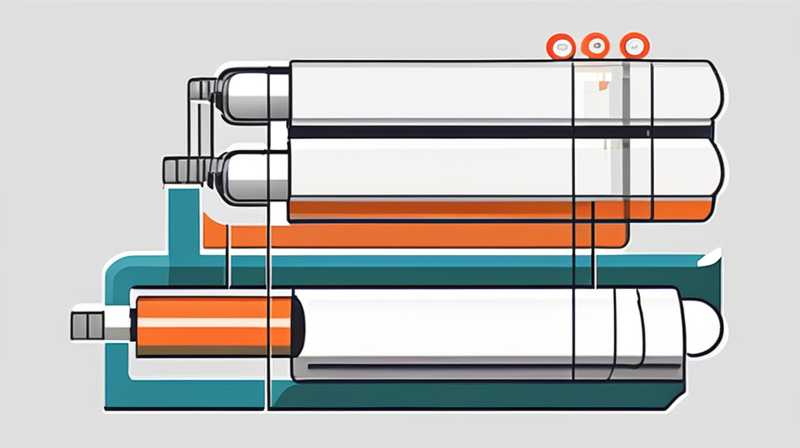

Solar PPR (Polypropylene Random Copolymer) pipes are extensively used in various systems due to their durability, resistance to heat, and capacity to facilitate water flow efficiently. These pipes have emerged as a popular choice in solar energy applications, particularly for transporting heated fluids.

Initially, it is crucial to recognize the composition and characteristics of solar PPR pipes. Their structure offers significant advantages, such as resistance to corrosion and flexibility. However, the installation of these pipes can face challenges, particularly when retrofitting or altering existing systems. Proper understanding of the application environment, thermal expansion characteristics, and compatibility with fittings is vital for safeguarding the entire system.

Maintaining an efficient flow is crucial in any piping system, and PPR pipes are no exception. Sluggish flow rates can result from blockages, which can arise due to sediment accumulation or improper installation. Such circumstances precipitate the need for a methodical approach to blocking these pipes when necessary, ensuring the desired system performance is retained.

FACTORS INFLUENCING BLOCKAGE METHODS

Various factors must be assessed when considering how to effectively block solar PPR pipes. The environment in which the pipes are placed significantly influences the methods utilized. For example, residential systems may call for different tactics compared to commercial or industrial setups.

Temperature fluctuations can impose significant stresses on PPR pipes, leading to expansion and contraction. Thus, thermal considerations play a pivotal role in the choice of blockage technique. The act of sealing can also vary in complexity based on whether the pipes are above ground or underground.

Additionally, it is necessary to consider the type of fluids being transported. For example, if the pipes are used in a heated water system, select materials that can withstand high temperatures while maintaining structural integrity. Consequently, evaluating the overall system requirements and conditions proves fundamental in determining the most appropriate method for blocking.

MATERIAL SELECTION

In selecting materials for blocking solar PPR pipes, compatibility with existing pipes must be prioritized. The ideal choice would be components made from similar materials to prevent unwanted reactions or degradation over time.

Common materials utilized in the blockage process include caps, plugs, and sealants. Threaded caps or push-fit caps can serve as temporary or permanent solutions based on the specific project needs. While choosing sealants, it is essential to ensure that they are specifically designed for use with PPR pipes to ensure effectiveness and longevity.

Specialized plumbing adhesives might also be used for a more permanent solution. Selecting suitable sealants demands consideration of factors such as temperature tolerance, pressure rating, and resistance to chemical degradation. A thorough assessment of the performance requirements will guide the best choice among the vast array of materials available on the market.

INSTALLATION METHODS

Several methods exist for effectively blocking solar PPR pipes, each tailored to the intended duration of blockage and specific system requirements. For permanent blockage, solid-end fittings or solvent welding can create a robust closure that is unlikely to fail. It is essential to follow the manufacturer’s recommendations during installation to avoid compromising the piping system.

Temporary solutions, such as employing threaded caps or butterfly valves, provide flexibility for maintenance while enabling operators to swiftly isolate sections of the piping system. Ensuring a snug fit during installation is paramount to prevent leaks, and care must be taken with threaded joints and seals to guarantee a tight assembly.

Proper installation further encompasses the use of tools like pipe cutters, torque wrenches, and ratchet sets. Training personnel on installation techniques is crucial to ensure reliability in maintaining the integrity of the water distribution system. Adequate time spent on proper installation contributes significantly to the blockage’s success.

REGULATORY CONSIDERATIONS

Compliance with local regulations is critical in the installation process of solar PPR pipes. Each region may impose specific codes regarding piping materials, installation methods, and blockage techniques. Neglecting these provisions can lead to penalties or hazardous situations.

Before commencing any blockage effort, it is essential to research the relevant local building codes. Obtaining necessary permits or permissions might be required for certain operations. Engaging a professional familiar with these regulations ensures the process remains within legal boundaries while maintaining safety standards.

It is also advisable to consult with local authorities or professional plumbing associations for guidance on best practices and current regulatory requirements. Maintaining documentation of compliance efforts serves as a safeguard should any issues arise in the future.

MAINTENANCE AND MONITORING

Ensuring the effectiveness of blocked solar PPR pipes necessitates ongoing maintenance and monitoring practices. Initial installation procedures will lay the groundwork for success, yet continued vigilance is paramount. Regular inspections and assessments can identify signs of wear, corrosion, or leaks that may arise.

During maintenance checks, it is essential to examine the condition of the blockages. This may involve removing caps or fittings to observe their integrity. If any anomalies are noted, prompt action can be taken to rectify potential issues. Keeping a maintenance log helps track any repairs or inspections performed, fostering a history that could be beneficial for future assessments.

Monitoring the environmental conditions surrounding the piping system also proves valuable. Changes in temperature, humidity, and surrounding soil conditions can affect the locked state of the pipes. Adapting to such changes through regular evaluations ensures long-term performance and system reliability.

FREQUENTLY ASKED QUESTIONS

WHAT ARE THE COMMON REASONS FOR BLOCKING SOLAR PPR PIPES?

Solar PPR pipes may require blockage for various reasons. One of the primary considerations is maintenance. Sometimes, portions of the system must be isolated to facilitate repairs without disrupting the entire circulation. Another reason might be the changing needs of the system itself; for example, a redesign or rerouting may require segments to be blocked ultimately. Additionally, in specific applications such as seasonal systems, there may be periods where temporary blockage is necessary. Any inappropriate materials or methods can lead to pipeline failure or system inefficiencies. Therefore, a well-planned strategy considering the reasons for blockage is essential.

HOW CAN I DETERMINE IF MY SOLAR PPR PIPE NEEDS BLOCKING?

Identifying the necessity for blocking involves multiple indicators. Observe for any signs of physical damage or leaks within the piping system. Visual inspections often reveal whether water is flowing as expected or if slowdowns are present, suggesting a blockage. Other indicators might include unusual sounds, water pressure fluctuations, or visible corrosion. Regular maintenance checks and monitoring can also facilitate early detection of potential issues. If uncertainty persists, it is beneficial to consult a professional plumber or technician who can evaluate the situation comprehensively and provide tailored recommendations.

WHAT IS THE BEST WAY TO PERMANENTLY BLOCK A SOLAR PPR PIPE?

To achieve a permanent blockage of a solar PPR pipe, utilizing solid-end fittings or solvent welding techniques is advisable. The materials must align with those of the pipe to avoid any material incompatibility. It is crucial to adhere to the manufacturer’s guidelines during installation to ensure successful adhesive bonding. A careful installation process will significantly extend the longevity of the blockage. Employing pressure and heat-resistant sealants or specialized adhesives designed for PPR applications plays a key role in the overall effectiveness of the blockage see where weaknesses may occur.

Fundamentally, understanding how to block solar PPR pipe entails comprehensively assessing the environment, materials, and methods employed. The selection of suitable blocking techniques is a multifaceted process influenced by various factors such as type, location, and duration of blockage required. Thorough knowledge of the composition and use of PPR pipes lays the groundwork for an appropriate approach. Areas like regulatory compliance, installation methods, and ongoing maintenance also contribute significantly to the efficacy of the blockage, ensuring that the entire piping system operates seamlessly while meeting safety standards.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-block-solar-ppr-pipe-2/