Assembling a solar panel can be an intricate yet rewarding process that ultimately leads to energy independence and sustainability. 1. Gather necessary components, 2. Understand different types of solar cells, 3. Choose an effective design, 4. Follow safety precautions, 5. Connect components accurately. One of the most critical aspects involves understanding the workings of solar cells, particularly their construction and efficiency. Quality solar cells convert sunlight into electricity, and familiarizing oneself with variations such as monocrystalline, polycrystalline, and thin-film technologies can significantly impact the performance of the assembled panel. Understanding the characteristics of each type will not only help you select the right components but also enhance your knowledge about energy efficiency, installation, and potential cost savings in the long term.

1. COMPONENTS REQUIRED FOR SOLAR PANEL ASSEMBLY

Assembling a solar panel involves several essential components that must be carefully selected and acquired. The fundamental elements include solar cells, a backing material, a protective front sheet, soldering materials, a junction box, and suitable wiring. Without these elements, efficiently capturing and converting solar energy remains an elusive goal. It is crucial to select high-quality solar cells, as they directly impact the energy output of your panel.

Moreover, the backing material must be durable enough to withstand environmental factors, while also being lightweight for ease of installation. Common choices are plywood and aluminum, each with distinct advantages; plywood is more economical, whereas aluminum offers superior longevity and weather resistance. The protective front sheet often consists of tempered glass, providing a shield against weather elements while ensuring that sunlight reaches the solar cells. Each part plays a specific role that culminates in the efficient functioning of the solar panel.

2. UNDERSTANDING SOLAR CELL TYPES

A significant factor in the decision-making process involves comprehension of the three primary types of solar cells available—monocrystalline, polycrystalline, and thin-film. Monocrystalline cells, recognized for their superior efficiency and space requirements, are crafted from a single crystal structure. This type offers the highest power output per surface area, making it an attractive option for those with limited space. Their distinctive black hue gives them an aesthetically pleasing appearance, which can be a deciding factor for some consumers.

On the other hand, polycrystalline solar cells exhibit a lower efficiency compared to monocrystalline, often resulting in slightly less power output per square meter. Constructed from multiple crystal structures, these cells are typically less expensive to manufacture, leading to a more budget-friendly option. Lastly, thin-film solar cells boast an extensive variety of uses due to their flexibility and lightweight nature. While their efficiency is lower, advancements in technology have led to improvements, making them a viable choice for specific applications, particularly in unconventional or portable setups. An informed selection of solar cell type will greatly influence the success of the assembled panel.

3. DESIGN AND ARRANGEMENT OF SOLAR CELLS

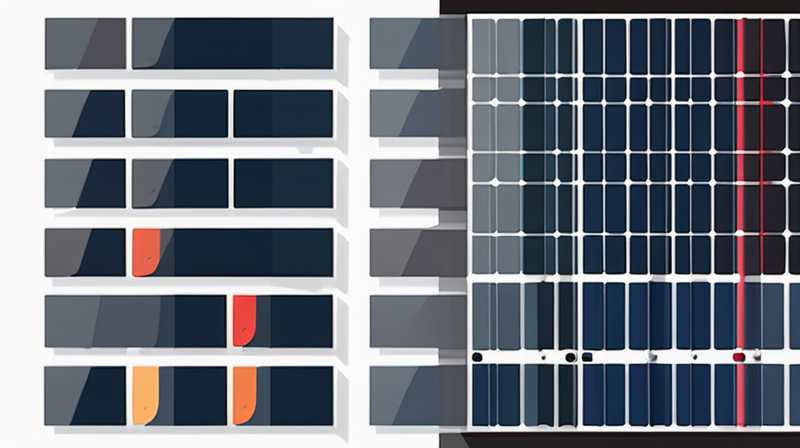

Creating an efficient layout for solar cells involves meticulous planning and consideration of various factors such as available space, desired output, and specific environmental conditions. The arrangement of cells can significantly affect the overall efficiency of the solar panel. A common configuration is a series-parallel array, where cells are connected both in series and in parallel to enhance voltage and current output.

It is essential to account for potential shading, as even a minor obstruction can lead to significant drops in performance. When positioning the cells, ensuring they receive maximum sunlight exposure throughout the day is vital. Utilizing simulation software can help visualize potential efficiencies based on layout changes and environmental factors, providing a strategic advantage before the actual assembly begins.

Additionally, incorporating a robust frame to support the solar cells not only lends structural integrity but also ensures protection from elements like wind and rain. A well-designed frame provides the necessary angle for sunlight capture, optimizing energy conversion. Thorough installation planning, focusing on these design elements, is pivotal for attaining desired functionality and performance from the assembled panel.

4. SAFETY PRECAUTIONS DURING ASSEMBLY

Safety must always be a foremost concern during the assembly of solar panels, as working with electrical components involves inherent risks. First and foremost, it is crucial to use appropriate personal protective equipment (PPE). Safety goggles, gloves, and sturdy footwear can help protect against any potential injuries during the assembly process.

Furthermore, while working with electricity, maintaining a dry and clean workspace is indispensable. Water and electrical components do not mix well, and any moisture can lead to dangerous situations. It is recommended to adhere to established electrical standards and regulations to ensure safe operation. Grounding the system effectively can also prevent malfunctions and accidents.

Moreover, being aware of the potential risks associated with using tools and equipment is essential. Ensuring tools are in good working condition and using them as per manufacturer specifications will minimize accidents. Taking the time to understand the hazards associated with each component further establishes a safe working environment. Taking these safety measures seriously significantly reduces the likelihood of mishaps during the assembly of solar panels.

5. CONNECTIONS AND CONFIGURATIONS IN SOLAR ASSEMBLY

The connection of solar cells and components results in the creation of a functioning solar panel. Accurate wiring will ensure efficient power transfer to the junction box, which plays a pivotal role in managing the overall functionality of the system. When connecting cells, soldering techniques are vital; proper soldering creates strong electrical connections that withstand the test of time and environmental changes.

The arrangement of the wiring is just as critical as the soldering technique. Adopting a clean and organized wiring layout will ensure that power flows smoothly without any interruptions. In certain configurations, incorporating bypass diodes into the junction box aids in mitigating the effects of shading, ultimately preserving the output of the entire panel. Understanding these intricate details is essential for achieving optimal performance and reliability from your solar panel setup.

In addition to wiring, appropriately configuring the output voltage is crucial. Depending on personal energy requirements, solar panel outputs can be tuned by adjusting the series and parallel connections. A thorough comprehension of basic electrical principles, such as Ohm’s Law, further aids in determining appropriate configurations. Consequently, gaining knowledge in these aspects is instrumental in ensuring that the assembled system functions effectively.

6. TESTING AND VALIDATION AFTER ASSEMBLY

Upon completing the solar panel assembly, thorough testing and validation are critical steps to ensure the system operates effectively. Utilizing a multimeter, measure voltage and current to validate the performance of individual solar cells. This process can reveal if any cells are underperforming or if connections need to be adjusted for optimal functionality.

Furthermore, running a small-scale test can help ascertain the overall efficiency before full installation. By testing under various light conditions, one can gain insights into how the panel performs throughout the day. Monitoring output at different angles throughout this testing phase can also inform decisions regarding the final mounting structure.

After ensuring the solar panel operates correctly, preparing for installation can begin. Choices regarding the mounting location and orientation will significantly impact performance. Ensuring that the solar panel is positioned to maximize exposure to sunlight throughout the day is paramount.

In essence, diligent testing creates a safety net, preventing future issues and ensuring that the assembled solar panel serves its intended purpose efficiently and effectively.

FAQs

WHAT TYPE OF SOLAR CELL IS MOST EFFICIENT?

When seeking maximum efficiency in solar energy capture, monocrystalline solar cells stand out as the most effective. These cells are created from high-purity silicon, resulting in a uniform appearance and greater electrical output. Their design allows for improved electron flow, leading to higher energy conversion rates—typically between 15% and 22%. One of the key advantages of monocrystalline cells is that they require less space than their counterparts to generate equivalent energy. This characteristic makes them particularly well-suited for residential installations where space might be limited.

Moreover, advancements in manufacturing technology continue to enhance the efficiency of monocrystalline cells. While they may carry a higher initial investment cost compared to polycrystalline or thin-film options, their longevity and durability often offset these expenses over time. Furthermore, many warranties on monocrystalline cells extend up to 25 years, providing assurance regarding their long-term performance. Given the increasing demand for energy efficiency, many consumers choose monocrystalline solar cells despite initial costs, confident in their superior energy generation abilities.

HOW LONG DOES IT TAKE TO ASSEMBLE A SOLAR PANEL?

The assembly time for a solar panel can be highly variable, depending on experience, complexity, and component availability. For someone well-versed in solar technology, the process can take anywhere from 5 to 10 hours. This includes gathering materials, designing layouts, soldering cells, and testing configurations before finalizing the setup. For novices, however, this timeline may extend significantly.

Several factors influence the pace of assembly. A clear understanding of solar cell characteristics, wiring techniques, and safety procedures contributes to a smoother process. Those who allocate ample time for planning can streamline the physical assembly phase. Moreover, the design complexity can dictate the timeline—panels requiring intricate connections and additional components may require extra hours to complete. By organizing tasks and allowing room for learning, individuals can manage their expectations regarding the assembly timeframe effectively.

WHAT ARE THE COMMON MISTAKES TO AVOID WHEN ASSEMBLING SOLAR PANELS?

Several prevalent pitfalls can hinder the successful assembly of solar panels. One common mistake is inaccurate soldering. Soldering connections poorly can lead to electrical failures or insufficient power transfer. It’s essential to use appropriate soldering techniques and tools, ensuring clean and secure connections to promote effective energy flow.

Another mistake involves failing to account for environmental factors, such as shading. Positioning the panels in areas not exposed to direct sunlight can drastically reduce their efficiency, rendering them ineffective. Additionally, neglecting safety protocols or working without proper personal protective equipment can lead to accidents and injuries.

Inadequate testing after assembly is another frequently encountered oversight. Failing to thoroughly test the system limits the ability to identify issues before the panels are installed, potentially resulting in energy losses. Throughout the assembly process, keeping these common missteps in mind can lead to a successful and rewarding solar panel design.

FINAL THOUGHTS

Embarking on the journey to assemble a solar panel is marked by diligence, patience, and thorough understanding of the underlying technologies involved. By sourcing quality components and gaining insight into various types of solar cells, individuals not only optimize their panel’s energy output but also contribute significantly toward sustainable energy usage. An organized design and careful arrangements of the solar cells ensure efficiency while considering safety precautions throughout the process minimizes risks.

Additionally, understanding the intricate connections and configurations of the components paves the way for effective solar energy capture. After the assembly phase, conducting rigorous testing guarantees proper functionality, ensuring that all connections and components perform as intended. Awareness of common mistakes serves as a safeguard against potential pitfalls, elevating the overall assembly experience. All of these efforts culminate in creating a functional solar panel that meets energy needs while aligning with eco-friendly principles. Ultimately, this venture not only fosters energy independence but also equips individuals with invaluable skills and knowledge that can lead to further advancements in renewable energy applications. Transitioning towards solar energy is a significant step towards a more sustainable future.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-assemble-your-own-solar-panel-2/