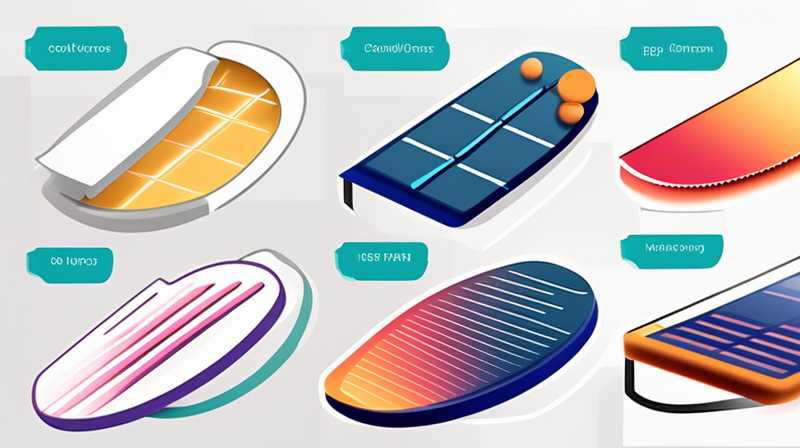

1. HOW TO ASSEMBLE SOLAR SILICON WAFERS

The process of assembling solar silicon wafers involves several critical steps, including 1. Understanding the materials and tools required, 2. Preparing the silicon for wafer production, 3. Fabricating the wafers through cutting and polishing, 4. Conducting quality checks and performance tests. It is essential to have a comprehensive understanding of these aspects, particularly the importance of material purity and precision during manufacture, as silicon wafers are integral to the efficiency and effectiveness of solar panels. An elaborate focus on quality assurance ensures that the final product meets industry standards, ultimately enhancing the performance of photovoltaic systems.

1. UNDERSTANDING MATERIALS AND TOOLS REQUIRED

The initial phase in assembling solar silicon wafers includes grasping the essential materials and tools needed for effective execution. Silicon, obtained in high purity from quartz or sand, forms the foundational element in this process. Polysilicon is the preferred form since it is both cost-effective and conducive to converting light into energy efficiently. Other materials such as phosphorous and boron are used as dopants to alter the electrical properties of silicon, enhancing its efficiency as a semiconductor.

To facilitate the manufacturing of wafers, a range of tools and equipment must be available. Crystal growing furnaces are vital for producing the polysilicon used in the wafers. Moreover, precision slicing saws are required for cutting the silicon blocks into thin wafers, typically around 200 micrometers in thickness. Chemical etching solutions are also crucial for preparing the surface of the wafers. A thorough understanding of these components is key to achieving high-quality wafers, laying the foundation for efficient solar cells.

2. PREPARING THE SILICON FOR WAFER PRODUCTION

Once the necessary materials and tools have been identified, preparing silicon for production becomes paramount. The process begins with melting the raw silicon, which is then subjected to crystallization to form ingots. These ingots, once solidified, require careful handling to maintain their structural integrity and purity.

The ingots are typically manufactured using the Czochralski process or the float-zone method, both techniques ensuring minimal contamination and optimal crystalline structure. With these methods, small amounts of dopants such as phosphorous are introduced to create n-type silicon or boron for p-type silicon. This step is crucial as it determines the electrical characteristics of the wafers, significantly impacting their performance in solar applications.

Following solidification, cooling the ingots must be executed slowly to avoid internal stresses that could lead to cracks. Proper cooling techniques not only enhance wafer quality but also extend the yield during later slicing processes.

3. FABRICATING THE WAFERS THROUGH CUTTING AND POLISHING

The next essential stage revolves around transforming the silicon ingots into individual wafers. This involves cutting, which is primarily done using diamond wire saws or other precision cutting technologies. Cutting into wafers necessitates a keen understanding of blade speed, tension, and feed rate to prevent wastage and ensure consistency.

After slicing, the wafers go through a meticulous polishing step to achieve the required flatness and surface finish. This is a critical aspect as any irregularities on the wafer can lead to inefficiencies in solar cell performance. Chemical mechanical polishing (CMP) is often employed here, allowing for the removal of surface defects and enhancing the wafers’ light absorption properties.

Attention to detail during this phase cannot be overstated. Each wafer’s surface must be thoroughly inspected to ensure it meets industry standards, with imperfections documented and accounted for. This process not only prepares the wafers for further processing but also contributes to the overall quality and efficacy of the final solar products.

4. CONDUCTING QUALITY CHECKS AND PERFORMANCE TESTS

Once the wafers are fabricated, quality assurance becomes the priority. A series of inspections and performance tests are conducted to assess the crystalline structure, surface integrity, and thickness of each wafer. Advanced techniques such as photoluminescence imaging and infrared spectroscopy provide insights into the wafers’ efficiency potential.

These quality checks ensure that only the best-performing wafers proceed to the solar cell production phase. Additionally, characteristics such as resistivity and minority carrier lifetime are measured to predict how effectively the silicon wafers will convert solar energy into electricity. Each parameter is meticulously documented, and any deviations from the benchmarks are critically analyzed to avoid any impacts on the end product’s performance.

Furthermore, sample testing is often conducted, where a subset of wafers undergoes accelerated degradation tests to simulate long-term usage. This proactive approach helps manufacturers identify any potential weaknesses or flaws early on, allowing for optimized production processes.

FAQS

WHAT IS THE ROLE OF DOPANTS IN SOLAR SILICON WAFERS?

Dopants play a significant role in determining the electrical properties of solar silicon wafers. By introducing specific elements like boron or phosphorus into the silicon crystal structure, manufacturers can create p-type or n-type silicon, respectively. This alteration enables improved charge carrier mobility within the wafer, resulting in better conductivity.

The choice of dopants influences several factors, including the photovoltaic efficiency and the temperature coefficient of the solar cells. Optimum doping concentrations are crucial, as they directly affect the balance between efficiency and material costs. Thorough research and understanding of how different dopants react within the crystalline lattice are essential for maximizing the performance of solar cells.

HOW DOES THE POLISHING PROCESS IMPACT SOLAR CELL EFFICIENCY?

The polishing process has a profound impact on solar cell efficiency due to its effect on the wafer’s surface quality. A smooth surface reduces light reflection, allowing more photons to penetrate the silicon and be converted into electricity. Additionally, polished wafers exhibit fewer defects, which can lead to recombination losses of charge carriers.

Employing advanced polishing techniques like chemical mechanical polishing helps achieve the necessary flatness and effectively removes contaminants. The result is not only a wafer that meets aesthetic standards but also one that maximizes energy conversion capabilities. The effects of polishing ripple throughout the entire photovoltaic system, underscoring its importance in wafer assembly.

WHAT ARE THE MAIN CHALLENGES IN SILICON WAFER PRODUCTION?

Silicon wafer production faces several challenges, including managing material purity and minimizing production costs. Maintaining high purity levels is vital, as contaminants can significantly impact solar cell efficiency. Manufacturers must continuously innovate to refine purification processes and optimize the dopant introduction methods.

Another challenge is the balance between wafer thickness and performance. Thinner wafers are more economical but may encounter issues relating to strength and structural integrity. Hence, manufacturers must navigate these trade-offs strategically to produce wafers that meet efficiency standards without compromising their physical reliability.

The assembly of solar silicon wafers is a multifaceted process requiring precision, deep understanding, and rigorous quality control measures to ensure the production of high-efficiency solar cells. Commencing with basic materials and tools, the entire journey from raw silicon to finished wafers presents numerous challenges and technical considerations. Achieving optimized assembly necessitates careful management at every critical phase, from crystallization to cutting and polishing. Quality checks and performance assessments serve as the backbone of this production, determining the potentials and limitations of the assembled wafers for solar applications. The continuous advancements in technologies and methods used in this field highlight the importance of maintaining material integrity and innovating processes to remain competitive. Furthermore, the pressures of economic feasibility merge with the demand for efficiency, compelling manufacturers to tread the delicate line between cost and performance. Each step in this assembly process plays a vital role in determining the efficiency and longevity of solar panels, emphasizing the impact that scientific precision and engineering finesse have in creating sustainable energy solutions for the future. The collective efforts of researchers and manufacturers thus converge on enhancing solar technology, contributing significantly to the global shift towards renewable energy sources.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-assemble-solar-silicon-wafers/