Assembling solar monocrystalline panels requires careful attention and a series of methodical steps. 1. Safety precautions must be taken before starting assembly, wearing protective gear. 2. Gather necessary tools such as a screwdriver and panel connectors. 3. Align the panels properly on a stable surface. 4. Establish a connection to the inverter, ensuring proper wiring. 5. Test the assembled system for functionality. A detailed elaboration on establishing a connection to the inverter is crucial. It’s important because this connection plays a vital role in the overall efficiency of the solar energy system. Proper wiring ensures that energy generated is effectively converted and transmitted for use. Incorrect connections could lead to energy loss or damage to the inverter, necessitating careful attention to the manufacturer’s guidelines during this stage.

1. SAFETY PRECAUTIONS

Engaging in the assembly of solar monocrystalline panels mandates a profound commitment to safety. Working with electrical components entails inherent risks; thus, individuals must equip themselves with the necessary protective gear. Wearing gloves can prevent cuts from sharp edges, while goggles shield the eyes from debris or accidental splashes from cleaning agents. Furthermore, proper footwear should be worn to prevent slipping, particularly if the assembly location is outdoors or on a rooftop.

In addition to personal protective equipment (PPE), awareness of the environmental conditions during assembly is paramount. For instance, assembling panels during inclement weather could expose workers to electric shock hazards or lead to falls, particularly if heights are involved. Therefore, checking the local weather forecast and planning the assembly for a clear day, when conditions are dry, can reduce risks significantly.

2. GATHERING NECESSARY TOOLS

Before embarking on the assembly process, one must carefully gather all the requisite tools and materials. Essential tools include a screwdriver, a wrench, wire connectors, and a multimeter. Each tool serves a specific purpose; for instance, the screwdriver is necessary for securing the panels to their frames, while the wrench aids in tightening bolts for secure connections.

In addition to these tools, gathering quality materials is vital. Using high-quality connectors ensures a robust electrical connection, minimizing the risk of loss in energy efficiency. The choice of wiring also plays a critical role; selecting the right gauge for the voltage requirements helps avoid overheating and improves the longevity of the system.

3. ALIGNING THE PANELS

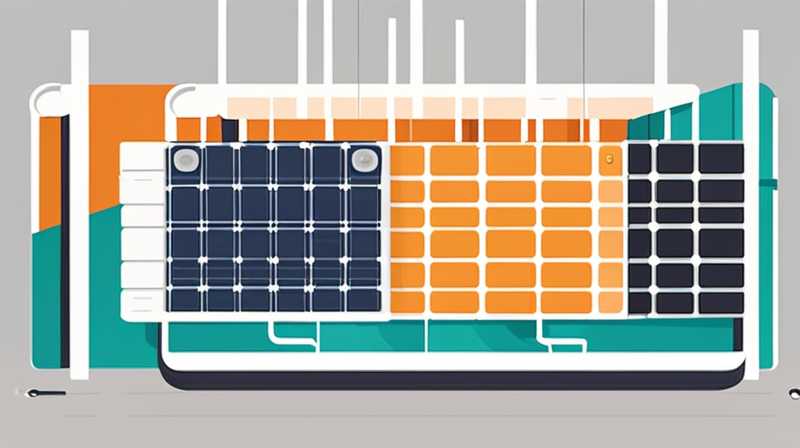

Once all tools and materials have been gathered, the next step is to align the solar monocrystalline panels properly. A stable surface is essential for the effective functioning of solar panels as even slight misalignment can result in lost efficiency. Ideally, panels should be positioned at an angle that maximizes sunlight exposure throughout the day, which varies depending on geographical location.

Before securing the panels in place, individuals should consider the spacing between them. Adequate gaps allow for air circulation, reducing the risk of overheating that can occur if panels are placed too close together. Once alignment is satisfactory, the next step involves securely fastening the panels, solidifying their position for longevity and effectiveness.

4. ESTABLISHING CONNECTION TO THE INVERTER

Establishing a connection to the inverter involves either solar stringing or combining the output from multiple panels to allow for efficient energy conversion. This process begins with identifying the positive and negative terminals on each panel to ensure accurate wiring. It is crucial to follow manufacturer guidelines meticulously when performing this task, as improper wiring can not only reduce efficacy but also pose safety risks.

Once connections are made, the use of a multimeter can assess the output voltage. This step verifies that the panels are functioning correctly and that the inverter is receiving the correct input for energy conversion. Performing these checks assures that the initial assembly aligns with expected performance standards, paving the way for further testing and configuration.

5. TESTING THE ASSEMBLED SYSTEM

After completing the physical assembly and wiring, it becomes imperative to conduct comprehensive testing of the newly established solar array. Testing ensures that all components work harmoniously, and allows for the identification of any potential issues early in the operation process. During this stage, checking connections for any signs of arcing or overheating is vital, as these can lead to catastrophic system failures.

Monitoring the energy output of the assembled system provides insight into its efficiency and functionality. Regular testing can reveal discrepancies between expected and actual performance which can indicate underlying issues. Moreover, implementing performance monitoring systems allows for effective long-term tracking of the energy output, assisting in maintaining optimal operation.

6. MAINTAINING SOLAR MONOCRYSTALLINE PANELS

Proper maintenance of solar monocrystalline panels is critical to ensuring their longevity and functionality. Routine cleaning is paramount; accumulation of dust and debris can significantly hinder energy production. Regular washing with water and a soft cloth ensures that the panels maintain maximum exposure to sunlight, preserving their high efficiency.

In addition to physical cleaning, it’s advisable to conduct periodic inspections of wiring and connections. The integrity of the connections must always be monitored to ensure there is no wear and tear that could lead to malfunctions. Keeping a diligent maintenance schedule can significantly enhance the lifespan and performance of solar panels, yielding better returns on the initial investment.

FAQs

WHAT ARE MONOCRYSTALLINE SOLAR PANELS?

Monocrystalline solar panels are a type of photovoltaic cell made from a single continuous crystal structure. Known for their high efficiency and space-saving characteristics, these panels have a uniform dark color that is distinguishable from polycrystalline panels, which have a speckled appearance. The manufacturing process involves slicing thin wafers from a cylindrical silicon ingot, allowing electrons to move freely in a single direction. This results in higher performance under low-light conditions and higher efficiency rates than many other solar panel types.

These panels are highly regarded for their longevity, often exceeding 25 years with proper maintenance. Their efficiency often ranges between 15% and 20%, making them ideal for residential installation where roof space might be limited. Though monocrystalline panels tend to be more expensive upfront compared to their counterparts, their exceptional performance and durability mean they frequently provide better returns over time.

HOW LONG DOES IT TAKE TO ASSEMBLE SOLAR MONOCRYSTALLINE PANELS?

The duration required to assemble solar monocrystalline panels can vary widely based on the scale of the installation and the experience level of the individuals involved. On average, three to six hours are needed to complete the entire process, including gathering tools, aligning panels, and establishing electrical connections. Efficient preparation can shave off time significantly, especially if all tools and materials are readily available.

For seasoned contractors, the process may take even less time. However, for beginners, ensuring that all steps are correctly implemented is essential, leading to a potentially longer assembly time. Including additional tasks, such as obtaining the necessary permits and conducting maintenance checks, could extend the timeline further. Therefore, while the physical assembly might not take long, a comprehensive approach to the entire installation process is recommended for optimal results.

WHAT FACTORS INFLUENCE THE EFFICIENCY OF SOLAR MONOCRYSTALLINE PANELS?

The efficiency of solar monocrystalline panels can be influenced by various factors, prominently including temperature, shading, and orientation. Higher temperatures can reduce the lifespan and efficiency of solar panels because, as all electrical components, they are less efficient at elevated temperatures. Ensuring adequate ventilation and spacing can alleviate some of the heat effects, thus preserving efficiency.

Additionally, adequate positioning and orientation are crucial; panels facing directly toward the sun maximize solar exposure. Even slight shading from nearby trees or buildings can dramatically decrease energy output. Regular inspections must be performed to mitigate shading issues, ensuring optimal performance throughout the day and across seasons.

ASSET OF ASSEMBLING SOLAR MONOCRYSTALLINE PANELS

The assembly of solar monocrystalline panels stands as a testament to sustainable energy solutions, aligning modern technology with environmental consciousness. Investing time and resources in this process is substantial not merely for electricity generation, but for a greater commitment to reducing carbon footprints and promoting renewable energy.

Throughout the assembly process, meticulous attention must be directed to safety, alignment, wiring, and ongoing maintenance. Each step requires patience and diligence to ensure the solar panels operate at peak efficiency. When assembled correctly, these panels promise exceptional benefits, including reduced energy costs and increased property value, alongside significant contributions to ecological sustainability.

Thus, engaging in the assembly of solar monocrystalline panels can be embarked upon with confidence and purpose, knowing that each action contributes positively towards a sustainable future.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-assemble-solar-monocrystalline-panels/