1. Assembling a solar-powered DIY car requires several key components and a systematic approach to ensure functionality and efficiency. 2. Essential materials include solar panels, a suitable frame, a motor, and battery storage for energy. 3. Thorough research on the required tools and assembly guidelines is crucial for success. 4. Attention to detail during the assembly process will significantly impact the vehicle’s performance and longevity.

1. INTRODUCTION TO SOLAR-POWERED DIY CARS

Building a solar-powered DIY car represents a compelling fusion of creativity and sustainability. This endeavor not only encourages environmental consciousness but also offers a hands-on learning experience in engineering and renewable energy technologies. To embark on such a project, one must first understand the primary components that form the framework of a solar vehicle.

In essence, solar-powered cars operate by converting sunlight into electrical energy, which is then utilized to power a motor. This involves a specialized set of components, including solar panels, batteries, an electric motor, and various structural materials to create a durable framework for the vehicle. Each component plays a vital role in maximizing the vehicle’s efficiency and functionality.

2. COMPONENTS REQUIRED FOR ASSEMBLY

2.1 SOLAR PANELS

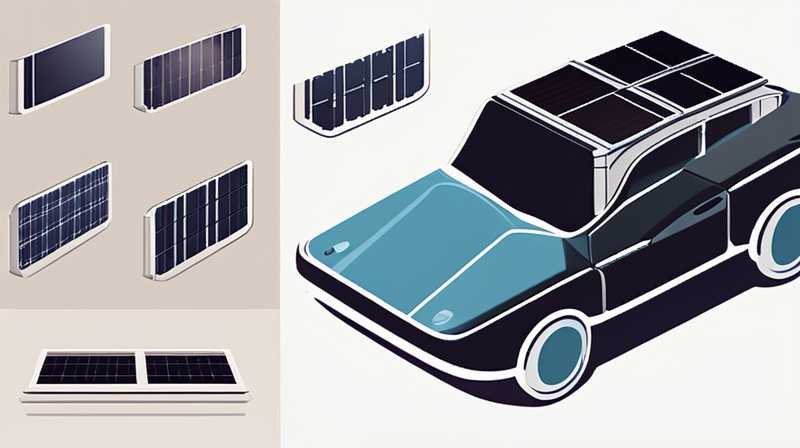

Solar panels serve as the heart of any solar-powered vehicle. These panels collect sunlight and convert it into DC electricity, which can either power the motor directly or charge a battery for later use. When selecting solar panels, it is essential to consider factors such as efficiency, surface area, weight, and durability.

For DIY projects, flexible solar panels might be preferable due to their lightweight nature and adaptability to various shapes. A panel’s wattage output will directly influence the vehicle’s speed and range, therefore, optimally choosing panels that meet the project’s specifications is crucial. Careful positioning of the solar panels is also significant; they should be mounted in such a way to maximize sun exposure throughout the day.

2.2 ELECTRIC MOTOR AND DRIVETRAIN

An electric motor plays a pivotal role in converting electrical energy into mechanical energy, driving the wheels of the car. Motors can be classified into various types such as brushed, brushless, and DCAC (Direct Current Alternating Current) motors. Each type has its advantages, and understanding these can help in selecting the appropriate motor for the DIY project.

The drivetrain comprises the components that transmit power from the motor to the wheels. This includes gearing systems, axles, and possibly a differential. The efficiency of the drivetrain is critical as it affects the overall performance of the vehicle. When assembling the components, it is painstakingly important to ensure that the motor and drivetrain are correctly aligned and fitted, as any misalignment can lead to diminished performance or even damage to the components.

3. DESIGNING THE FRAME

3.1 CHOOSING MATERIALS

The frame serves as the structural foundation of the solar-powered car. Choosing the right materials is vital, as the weight and durability of the frame will impact the vehicle’s overall efficiency. Common materials include aluminum, wood, or plastic, each offering distinct advantages and limitations.

Aluminum is highly favored for its lightweight characteristics and resistance to rust, while wood can be easy to work with but may not provide the desired strength or wear resistance. Cost-effective alternatives like plastic can also be considered, especially for prototyping purposes. Ultimately, the choice of material should reflect the project’s budget, intended use, and environmental considerations.

3.2 FRAME DESIGN AND AERODYNAMICS

Creating an efficient frame design is an essential factor influencing the performance of the solar-powered vehicle. A well-thought-out design not only accommodates the solar panels and motor but also ensures optimal aerodynamics. A streamlined shape minimizes air resistance, allowing the car to travel efficiently at higher speeds.

Considerations in design should include the positioning of the wheels, weight distribution, and space for additional components like batteries or control systems. Ensuring a low center of gravity can enhance stability during motion. Integrating features such as adjustable mounts for the solar panels can also provide flexibility for maximizing solar exposure.

4. ASSEMBLY PROCESS

4.1 STEP-BY-STEP ASSEMBLY

Commencing the assembly process requires meticulous planning and organization of all components. Start by constructing the frame according to the design specifications, ensuring all joints are secured for stability. After the frame is complete, install the motor and drivetrain, taking care to align all mechanical components correctly to prevent future issues.

Once the motor is secured, proceed to mount the solar panels on the designated spots on the frame. Wiring connections must be made with precision to prevent malfunctions. Connect the panels to the battery storage system, ensuring proper polarity and secure connections to allow efficient energy transfer.

4.2 WIRING AND ELECTRICAL CONFIGURATION

The electrical configuration is a crucial aspect of a solar-powered vehicle. The wiring system must be organized to manage the flow of electricity from solar panels to the motor and battery. Utilize high-quality, insulated wires to prevent potential losses or short circuits.

Ensure that all electrical components are rated for the current and voltage they will handle. The integration of fuses and circuit breakers is also advisable as a preventive measure against electrical failures. Testing the electrical system is pivotal before finalizing the assembly; conducting these tests ensures that all components function harmoniously.

5. TESTING AND OPTIMIZING PERFORMANCE

5.1 TESTING PROCEDURES

After assembly, undertaking a series of tests is paramount to ascertain the vehicle’s functionality. Begin with a static test of the electrical system, followed by a dynamic test where the vehicle is driven in a controlled environment. Monitor key metrics such as speed, acceleration, and battery performance during these tests.

Adjustments may be necessary based on testing outcomes. For instance, if the vehicle is underperforming, tweaking factors such as the angle of the solar panels or the gearing ratio may yield improved results. Ensuring a proper balance of weight and aerodynamics is essential to optimize the vehicle’s performance.

5.2 MAINTENANCE AND LONG-TERM CONSIDERATIONS

Post-testing, developing a maintenance routine can prolong the vehicle’s lifespan and enhance its productivity. Regularly inspect solar panels for cleanliness and functionality, as dirt or debris can significantly hinder energy absorption. Additionally, check the motor and drivetrain components for signs of wear or misalignment, as timely interventions can prevent costly repairs.

Long-term considerations also include exploring opportunities for upgrades or enhancements, such as more efficient solar panels or advanced battery technology. Maintaining an iterative approach toward the vehicle’s performance will foster continual improvement and sustainability in this DIY project.

FREQUENTLY ASKED QUESTIONS

WHAT TYPE OF SOLAR PANELS SHOULD I USE FOR A DIY CAR?

Choosing the right solar panels for a DIY solar-powered car is critical for optimizing performance. There are several types to consider, including monocrystalline, polycrystalline, and thin-film solar panels. Monocrystalline panels are known for their high efficiency and longevity, making them ideal for limited space. Although they tend to be more expensive, their superior efficiency can yield more power in smaller areas.

Polycrystalline panels are generally less efficient but can be a more economical option. They are characterized by their blue hue and often have a slightly lower power output than monocrystalline counterparts. Thin-film panels offer flexibility and lightweight characteristics, making them suitable for unconventional designs. Ultimately, the choice should align with budget constraints and project specifications, as these factors significantly impact the overall system’s performance.

HOW DO I CALCULATE THE POWER REQUIREMENTS FOR MY SOLAR-POWERED CAR?

Calculating the power requirements for a solar-powered vehicle involves assessing the total energy needed to operate the car efficiently. Begin by identifying the motor specifications, including its voltage and current ratings, to understand the baseline energy consumption. It’s essential to consider the expected driving range and duration to estimate the total energy consumption in watt-hours.

Once the motor requirements are established, factor in the potential output of your solar panels, taking into account their efficiency and average sunlight hours available in your area. The energy stored in the batteries needs to cover periods without sunlight, ensuring the vehicle can continue operating. Using this information, create a detailed energy budget that includes losses in efficiency, safety margins, and any additional components requiring power.

WHAT ARE SOME COMMON CHALLENGES IN ASSEMBLING A SOLAR-POWERED CAR?

Various challenges can arise during the assembly of a solar-powered DIY car. One prevalent issue is ensuring all components are compatible, notably the motor, batteries, and solar panels. Misalignment or faulty connections can lead to decreased performance or even complete failure of the system, making diligent research and planning essential prior to assembly.

Another challenge is effectively managing the vehicle’s weight. Balancing the benefits of solarpowered efficiency with the structural integrity of the car can be difficult, particularly when using heavier materials or accessories. Assembling a prototype that meets performance expectations while remaining within budget constraints often necessitates multiple iterations and adjustments, demanding patience and dedication to overcome these common hurdles.

FINAL THOUGHTS

Constructing a solar-powered DIY car is an enriching journey that merges engineering skills and environmental consciousness. Throughout the assembly process, every component—from the solar panels to the drivetrain—plays a crucial role in determining the vehicle’s functionality. Engaging in this project can not only yield a tangible result in the form of a self-sustaining vehicle but also contribute to a deeper understanding of renewable energy principles, which is increasingly vital in today’s world.

Moreover, undertaking such a venture highlights the significance of innovation in response to global energy challenges. Every DIY solar-powered vehicle contributes to the greater movement towards sustainable transportation solutions, serving as a testament to human ingenuity in harnessing renewable resources. The process encourages experimentation and iteration, allowing creators to explore technological advancements and improvements that can further optimize their designs.

Ultimately, this project extends beyond mere technical learning; it cultivates skills in precision, problem-solving, and creativity. Those who delve into assembling solar-powered vehicles often find themselves equipped with knowledge applicable to various fields, including engineering, environmental science, and even art. The endeavor encapsulates the exciting intersection of sustainability and innovation, paving the way for future advancements in personal transportation and renewable energy solutions.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-assemble-a-solar-powered-diy-car/