To successfully assemble a homemade solar car, one must follow a series of methodical steps that guarantee functional design, efficiency, and environmental sustainability. 1. Gather essential materials like solar panels, motors, and tires, 2. Design the structure to maximize airflow and reduce weight, 3. Assemble the components ensuring proper electrical connections, 4. Test functionality under sunlight to evaluate performance. Detailed attention to the arrangement of the solar cells is crucial, as it directly influences the energy captured and, consequently, the vehicle’s speed and efficiency. Effective insulation of electrical components is paramount to safeguard functionality and ensure durability during operation.

1. INTRODUCTION TO SOLAR CARS

Solar cars are innovative vehicles that harness solar energy to operate. These environmentally friendly machines utilize solar panels to convert sunlight into electricity, powering the vehicle’s motor. The appeal of solar cars lies in their potential to reduce carbon footprints while promoting sustainable development. Building a solar car at home can serve both educational and practical purposes. This endeavor introduces concepts of renewable energy and mechanics in an engaging manner.

Understanding the fundamental components of a solar car is crucial for anyone embarking on this project. Key parts include solar panels, battery storage, an electric motor, and wheels. Each component plays a significant role in the car’s overall functionality. Solar panels collect sunlight, converting it into electrical energy, which is stored in batteries. This stored energy is utilized by the electric motor to propel the vehicle.

2. MATERIALS REQUIRED

To initiate the assembly of a solar car, one must gather various materials. The selection and quality of these items can significantly influence the vehicle’s performance and longevity.

SOLAR PANELS are the first essential component. Depending on the size of the solar car, the total wattage of the panels will vary. Smaller projects may require solar panels with a wattage ranging from 5 to 50 watts, while larger builds may need panels rated at 100 watts or more. Higher wattage will generally lead to increased energy capture, propelling the vehicle at faster speeds.

MOTORS come next. An electric motor converts electrical energy into mechanical energy, driving the wheels of the car. GEARED DC or brushless motors are typically used due to their efficiency and performance characteristics. The right motor selection will depend on the vehicle’s weight and the desired speed; a motor with a higher RPM (revolutions per minute) will provide faster speeds.

Other materials required include battery storage systems to store energy, chassis materials like lightweight wood or aluminum, and wheels alongside an axle to facilitate movement. An understanding of electrical wiring is also important, as wiring connects various components to create a functioning system.

3. DESIGNING THE STRUCTURE

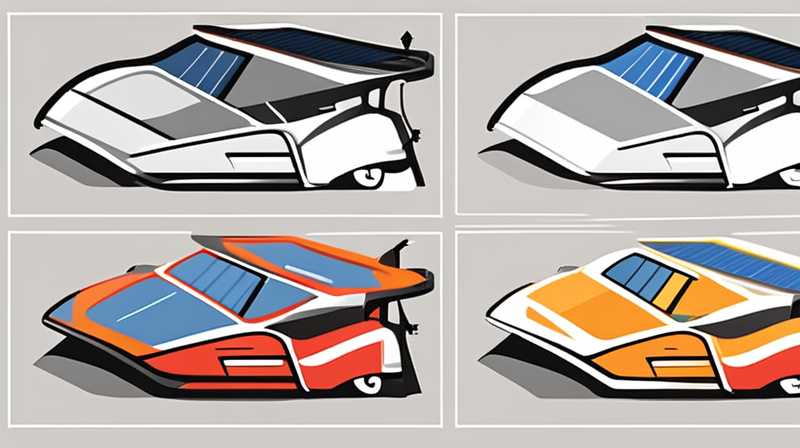

Creating an efficient design for the solar car involves considering aerodynamics and weight. The vehicle’s shape can greatly influence how it cuts through air, affecting speed and energy consumption. A streamlined profile will reduce air resistance, allowing for greater speed with less energy expenditure.

WEIGHT DISTRIBUTION must also be taken into account. A well-balanced car ensures that all wheels make optimum contact with the ground, enhancing stability and performance. Light materials such as plastics and thin woods are often favored for conserving energy and providing ease of maneuverability. Ideally, the design should incorporate a low center of gravity to prevent tipping and ensure balanced driving dynamics.

Equally important are the mounting locations for solar panels. The panels ought to be placed at an optimal angle to capture sunlight effectively. Angling the cells can maximize sunlight exposure throughout the day. Some designs utilize adjustable mounts that can be repositioned to follow the sun, although this adds complexity to the build.

4. ASSEMBLING THE PARTS

With the components gathered and a solid design in place, assembly can begin. This stage requires meticulous attention to detail, ensuring that all elements are integrated correctly for optimal performance.

CONNECTING THE SOLAR PANELS is the first step. When attaching solar panels, use appropriate adhesives or mounting hardware to secure them to the chassis. Each panel should be connected in a series or parallel configuration, depending on the desired voltage output. This step is vital because incorrect wiring can lead to underperformance or failure.

INSTALLING THE MOTOR is next. The motor should be secured firmly in place with appropriate brackets and affixed to the chassis. Carefully connect the wiring from the solar panels to the motor via the battery. A charge controller may be added to regulate voltage flow and protect batteries from overcharging, enhancing safety and battery life.

Next, attach the wheels and axle. Proper alignment ensures even wheel rotation. If the wheels are misaligned, the car may pull to one side or operate inefficiently.

Once assemblage is complete, effective insulation around electrical components is necessary to protect against environmental elements. This will enhance the longevity of the solar car and contribute to its effective functioning during use.

5. TESTING AND ADJUSTMENTS

After assembly, a series of tests must be conducted to evaluate the efficacy of the solar car. Initial testing typically occurs on a sunny day to harness maximum solar energy. Conduct practical tests to gauge performance in terms of speed and maneuverability under load conditions. Testing will ensure that the vehicle operates as expected, uncovering any issues that may need repair.

It is crucial to observe how the vehicle behaves under different conditions, including varied sunlight intensity and road surfaces. Documenting performance metrics will provide insight needed for future modifications.

If certain components underperform or show potential for improvement, adjustments can be made. For instance, if speed is insufficient, evaluate whether the motor provides adequate output for the vehicle’s weight. This might involve substituting a more powerful motor or optimizing the solar panel configuration for increased energy capture.

Regular maintenance after initial testing also ensures that the solar car remains functional. Periodic checks on the solar panels for cleanliness, battery health, and motor efficiency will prolong the vehicle’s lifespan.

6. ENHANCEMENTS AND CUSTOMIZATIONS

For those seeking to revolutionize their solar car project, numerous modifications and enhancements can take the basic design to impressive levels. These advancements can center around efficiency improvements, performance upgrades, or even aesthetic customizations.

INCORPORATING LIGHTWEIGHT MATERIALS is one potential upgrade. Advanced materials such as carbon fiber and specialized plastics can reduce overall weight while enhancing durability. By lightening the load, the efficiency of solar energy conversion can be improved, ultimately leading to better speed and performance.

AERODYNAMIC IMPROVEMENTS are essential for maximizing performance, too. Further refinements to the car’s exterior can greatly enhance airflow, which reduces drag. Innovations such as winglets or fairings can be added to the car’s design, assisting in its ability to manage wind resistance effectively.

From a technical standpoint, installing a more sophisticated battery management system could optimize energy usage. With programmable circuits, users can better track energy consumption, storage levels, and operational modes based on environmental conditions.

Moreover, the visual aspect of the solar car can also be transformed. By customizing the paintwork or integrating artwork, a personal touch can be added, making the vehicle distinctly unique. Custom designs make the solar car more appealing and provide an avenue for creative expression while encouraging individual engagement with the project.

7. ENVIRONMENTAL IMPACT AND EDUCATION

Engaging in the assembly of a solar car is not just an innovative hobby; it also cultivates awareness of environmental issues and renewable energy solutions. This hands-on experience highlights the importance of sustainable practices.

By utilizing renewable energy sources, contributions towards decreasing reliance on fossil fuels are realized. Understanding these principles can inspire individuals to consider more sustainable choices in their everyday lives. Additionally, as communities adopt similar projects, the broader impact leads to better awareness of climate change and energy conservation.

Educational institutions can incorporate such initiatives into science curricula, allowing students to grasp real-world applications of theoretical concepts. From physics to environmental science, solar car projects connect various academic disciplines while fostering collaboration and problem-solving skills.

The long-term ambition towards renewable energy efficiency can also be highlighted through these projects. As individuals embrace solar technology, further advancements in engineering and clean energy become paramount in addressing global challenges. Such awareness is vital for nurturing the next generation of innovators dedicated to sustainable development.

FAQS

WHAT IS THE COST OF BUILDING A SOLAR CAR?

The expense of constructing a solar car can significantly vary based on numerous factors, including materials chosen and scale of the project. A basic model may start around $200, incorporating inexpensive components, while advanced designs utilizing sophisticated materials can exceed $1,000. Solar panels typically represent a sizable portion of the total cost; opting for higher efficiency cells will increase overall expenses but can justify the investment through improved performance. Battery costs fluctuate based on capacity and type, with lithium-ion batteries being on the higher end yet prized for efficiency and longevity. Other considerations include tools, additional hardware, or enhancements which can further add to the budget. Planning and seeking out cost-effective materials while focusing on maximizing efficiency allows for a balance between expenditure and functionality.

CAN YOU USE REGULAR BATTERIES WITH A SOLAR CAR?

Yes, incorporating conventional batteries in your solar car design is feasible, but there are important considerations. Regular lead-acid batteries can serve as an option, however, they come with weight and efficiency drawbacks compared to lithium-based batteries. Lead-acid batteries have a shorter lifespan and may require more frequent replacement, unlike modern lithium batteries which offer higher energy density and longer life spans. Compatibility with the motor’s voltage requirements must also be ensured, as improper voltage can lead to underperformance or damage. Selecting the correct type of battery correlates with the overall efficiency of the vehicle, emphasizing the need for careful assessment of energy storage choices.

HOW DO YOU IMPROVE YOUR SOLAR CAR’S PERFORMANCE?

Enhancing a solar car’s performance can be achieved through a variety of methods. One of the most impactful measures is selecting high-efficiency solar panels designed to maximize energy capture per sunlight unit. Optimizing the angle of the panels is essential as well, ensuring that they are positioned to collect maximum solar energy throughout daylight hours. Additionally, reducing weight through the use of lighter materials, enhancing the aerodynamics of the vehicle, and ensuring all components are properly aligned can improve speed and handling. Regular maintenance involving cleaning solar panels and checking battery health further aids performance. Incorporating smart technology that tracks energy consumption can also inform adjustments leading to improved operational efficiency.

SOLAR CARS PROMOTE A SUSTAINABLE FUTURE

The adoptive practices of solar vehicles ultimately point towards a sustainable future. Engaging with the concepts of renewable energy and innovative engineering fosters a deeper awareness of environmental challenges. As individuals gain skills in constructing solar cars, they become equipped to make informed decisions regarding energy consumption and environmental stewardship. The associated educational benefits, such as collaborative problem-solving and application of theoretical knowledge, also contribute to nurturing a generation of forward-thinking individuals committed to advancing renewable technologies.

Solar cars symbolize a progressive shift toward environmental consciousness and innovative problem-solving. Engaging in such projects encourages personal responsibility for energy use, fostering a culture of sustainability. The practice extends values and practical insights on renewable energy and empowers individuals and communities to pursue further developments in green technologies. The overall journey of assembling a solar car offers invaluable lessons, rich awareness, and potential advancements in both personal skillsets and societal practices. The cultivation of inventive concepts leads to a future enriched with opportunities for harnessing clean energy solutions. Thus, home-built solar cars are not just projects but gateways to a broader understanding of sustainable living. By embracing these ideals through practical applications, individuals can significantly contribute to a cleaner, greener world while promoting the importance of alternative energy sources.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-assemble-a-homemade-solar-car/