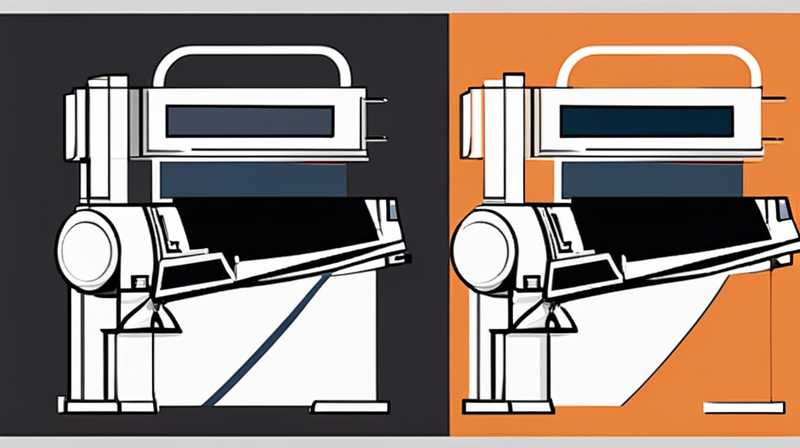

The process of adjusting a solar screen printing machine is crucial for ensuring high-quality prints and efficient operation. 1. Proper alignment of the screen with the substrate is paramount, as misalignment can lead to distorted images and wasted materials. 2. Tension settings require meticulous calibration, since improper tension can affect the ink transfer and reproduction quality. 3. The screen coating consistency must be monitored closely, as variations can lead to inconsistencies in image transfer. 4. Regular maintenance and clean-up of components, especially the squeegees and screens, are essential to prolong the longevity of the equipment and prevent contamination.

Let’s delve deeper into these points to understand the significance of proper adjustments and techniques associated with using a solar screen printing machine.

1. ALIGNMENT OF SCREEN AND SUBSTRATE

Before the printing process begins, accurate alignment of the screen with the substrate is essential. Misalignment can lead not only to wasted materials but also to subpar prints that do not meet quality expectations. Adjusting the registration marks on the machine helps in aligning the designs perfectly on various substrates, be it textiles, paper, or other materials.

Utilizing the machine’s adjustable clamps or holders enables the operator to position the screen accurately over the substrate. This involves ensuring that the selected design is centered appropriately, which is particularly vital for intricate designs requiring precise placement. Utilizing visual guides or laser alignment tools can significantly improve accuracy. Furthermore, it is noteworthy that some advanced machines come with built-in digital registration systems that can simplify this process, ensuring higher precision in alignment.

2. CALIBRATION OF TENSION SETTINGS

The significance of proper tension cannot be overstated in screen printing. Tension settings determine the quality of ink transfer and ultimately affect the reproduction of the printed image. Screens that are too tight may lead to unwanted pressure on the ink, while screens with insufficient tension can result in less control over the print, affecting the sharpness and detail of the print.

Adjusting the tension carefully requires a balance; using an appropriate tension gauge can help achieve optimal settings. Typically, the desired tension may vary depending on the type of ink used, the substrate, and the specific requirements of the print job. Operators should consistently test prints with minor adjustments to gauge how tension changes affect final outputs. Regular checks and calibrations of tension ensure that the screen maintains its desired performance over time.

3. MONITORING SCREEN COATING CONSISTENCY

The coating applied to the screen, usually a photosensitive emulsion, is another critical aspect of ensuring quality prints. Consistency in screen coating is vital to maintaining quality image transfer. Variations in the thickness and application can lead to blurry or faded prints, hampering the overall effectiveness of the printing process.

To achieve uniformity in coating, techniques such as using a coating trough to spread the emulsion evenly can be employed. Additionally, control over environmental factors such as humidity and temperature is essential, as these can affect how the emulsion adheres and develops. Following specific guidelines for drying and curing the coated screens also plays a role in achieving a robust image transfer.

4. MAINTENANCE AND CLEANING PROCESSES

One of the most overlooked aspects of operating a solar screen printing machine is the regular maintenance of its components. Maintaining clean and well-functioning parts dramatically extends the equipment’s lifespan and maintains quality prints over time. Regularly inspecting and cleaning squeegees and screens ensures that neighboring colors do not mix and that ink does not clog the mesh, leading to defects in the print.

The maintenance regime should include cleaning solutions tailored for screen printing applications. Properly disposing of used inks and emulsions is also paramount to ensure workplace safety and environmental precautions. Fine-tuning the machine settings after a cleaning ensures that everything is reset for optimal performance. Regularly scheduled maintenance checks should be standardized to prevent any potential issues from escalating into larger problems.

FREQUENTLY ASKED QUESTIONS

WHAT IS THE IMPORTANCE OF TENSION IN SCREEN PRINTING?

Tension in screen printing is of vital importance as it directly influences the quality of the print produced. Proper screen tension ensures that the ink transfers smoothly and evenly onto the substrate, allowing for detailed and sharp designs. If the screen is too loose, it may not hold the shape of the design correctly, leading to blurred and distorted images. On the other hand, excessively tight screens can create problems such as excessive ink pressure, which can also compromise image quality by causing runs or inconsistencies.

Achieving the correct tension is a balancing act that requires experience and careful adjustment. Various factors, including the type of material being printed on and the viscosity of the ink, influence the ideal tension setting. Regular testing and calibration of the tension setting during the printing process can ensure that the desired quality is consistently achieved. Ultimately, proper tension contributes significantly to the overall effectiveness and efficiency of the screen printing process.

HOW DO YOU DETERMINE THE CORRECT SCREEN ALIGNMENT?

Determining the correct screen alignment involves several steps that focus on precision and attention to detail. First, operators should set clear registration marks on both the screen and substrate, which serve as guides for alignment. These marks should be prominently visible and easily accessible for quick reference during the setup process.

Using adjustable clamps or holders on the machine is essential for ensuring that the screen is held securely in place while still allowing for adjustments. The alignment process may also benefit from the use of laser alignment devices, which can project lines to ensure perfect positioning of the screen in relation to the substrate.

Once the screen appears to be aligned correctly, conducting test prints is crucial. This allows for verification of alignment and provides an opportunity to make any necessary corrections before commencing with the full batch. Regular training and practice with alignment techniques can enhance the skill level of operators in accurately setting up the screen.

WHAT MAINTENANCE STEPS SHOULD BE TAKEN FOR A SOLAR SCREEN PRINTING MACHINE?

Maintaining a solar screen printing machine involves a comprehensive approach to ensure its longevity and optimal performance. Regular cleaning of components like squeegees, screens, and meshing is essential to prevent ink build-up and blockages that affect print quality. Using specialized cleaning solutions designed for screen printing applications helps in maintaining cleanliness without damaging the screen materials.

Furthermore, operators should be vigilant about checking for wear and tear on mechanical parts and replacing any components as necessary. Scheduled maintenance checks should be established to regularly inspect various elements of the machine. This includes ensuring that all moving parts are adequately lubricated and free from obstructions.

Finally, maintaining a tidy workspace helps reduce the risk of contamination and hazards. Implementing training sessions for operators not only improves their capabilities but reinforces the importance of maintenance and care for the printing equipment.

Skillful adjustments and preventive measures in solar screen printing machines are paramount to achieving quality outputs. Through careful alignment, proper tension settings, consistent coating application, and diligent maintenance practices, operators can ensure high-fidelity prints and prolong the functionality of their equipment. Each element intricately intertwines to create a seamless printing process, reflecting the importance of precision in the craft of screen printing. In embracing meticulous protocols and understanding the nuances of each component’s role, one significantly enhances both efficiency and product quality. In a competitive market where excellence is essential, optimizing machine adjustments stands as a foundational practice, safeguarding artistry and promoting operational success in screen printing endeavors. Operator training and adherence to these detailed processes are essential to navigate the intricacies associated with machine adjustments. Merging knowledge with practical application empowers screen printing professionals to achieve their artistic vision while delivering consistently superior products.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-to-adjust-the-solar-screen-printing-machine/