How thick is the telescopic solar panel?

1. The thickness of telescopic solar panels varies based on design, usage, and manufacturer specifications, 2. Typically, they range from 1/8 inch to 1 inch, 3. Thinner panels provide flexibility and lightweight benefits, 4. Thicker options often offer durability and better energy efficiency, 5. Key factors influencing thickness include material choice and intended deployment environments. A deeper understanding of the materials used in these panels, such as monocrystalline or polycrystalline silicon, can reveal how their thickness affects performance. For instance, monocrystalline solar panels, which are often thicker due to their more rigorous manufacturing processes, tend to have higher efficiency rates than their thinner counterparts. This additional thickness can also lead to enhanced durability against environmental factors, which is crucial for panels designed for telescopic systems that may be exposed to varying climates.

1. UNDERSTANDING TELESCOPIC SOLAR PANELS

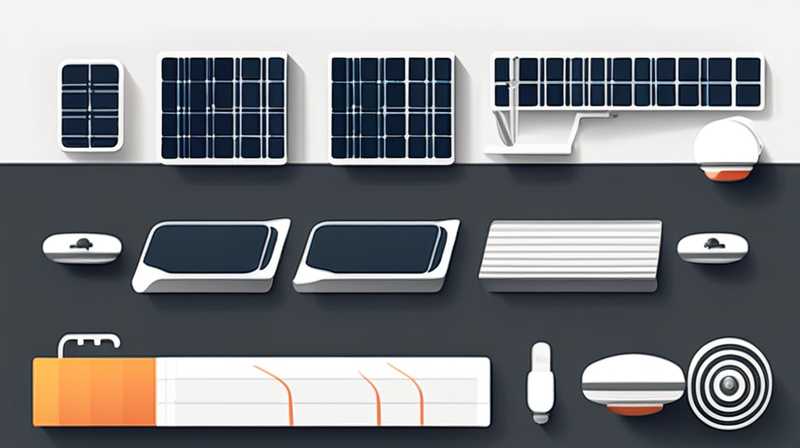

The advent of telescopic solar panels has revolutionized renewable energy technologies by introducing adaptable solutions for energy gathering. These unique solar panels are designed to extend and retract, optimizing their surface area exposure based on specific energy needs and environmental conditions. The engineering behind these panels revolves around maximizing efficiency while minimizing material use and overall weight. A critical aspect of this technology is the panel thickness, which significantly influences not only the physical integrity but also the performance output of the entire system.

Telescopic solar panels are prominent in applications ranging from residential installations to portable energy solutions for outdoor and off-grid scenarios. With fluctuations in solar exposure based on geographical location, retractable designs provide operators with the ability to adjust panel orientation and thickness as required. Such advancements highlight the importance of understanding how thickness contributes to performance metrics like energy absorption efficiency, heat tolerance, and structural resilience.

2. MATERIALS USED IN TELESCOPIC SOLAR PANELS

The materials employed in the construction of telescopic solar panels play a decisive role in determining their thickness and overall efficiency. Commonly, materials include monocrystalline, polycrystalline, and thin-film technologies, each offering distinct characteristics that affect their respective thickness.

Monocrystalline panels typically exhibit a thicker profile due to the purity of the silicon used in their production processes. This high purity not only means that each panel is capable of a higher energy conversion efficiency but also provides increased longevity and durability. As such, the extra thickness can be advantageous in maintaining performance and easing maintenance needs over the panel’s lifespan. The molecular structure of monocrystalline silicon also contributes to its ability to generate power even under low-light conditions, which is crucial for telescopic applications where sun exposure may vary.

On the other hand, polycrystalline panels, while slightly thinner, also present a compelling option with a balance of cost-effectiveness and adequate efficiency. Their manufacturing process results in a lower energy yield compared to monocrystalline panels. However, polycrystalline panels command a lower price and can still be efficient for extensive applications when managed correctly. Finally, thin-film solar panels, while the least bulky option, are often less efficient per square foot. These panels open up possibilities for flexible, lightweight applications, though their lower thickness can lead to vulnerabilities unless supported adequately.

3. FUNCTIONALITY AND ADVANTAGES OF THICKNESS IN DESIGN

Thickness in telescopic solar panels carries various functional advantages. Greater thickness often translates to improved durability and resistance to environmental stressors, which is paramount for outdoor installations. As panels are extended or retracted in varying weather conditions, durability becomes critical. Thicker models are generally built to resist hail, high winds, and fluctuating temperatures, thereby ensuring continuous operation without significant degradation over time.

The energy efficiency of solar panels is also inherently linked to their thickness—thicker panels, often containing more silicon material, can harness sunlight more effectively, leading to higher energy outputs. This impact on performance is essential for users who depend on these panels to achieve specific energy needs, particularly in off-grid living situations or during extended outdoor expeditions. Furthermore, as the demand for energy-efficient solutions grows, having a firm understanding of how thickness contributes to energy absorption is vital for making informed decisions in purchasing and deploying solar technology.

4. CHALLENGES ASSOCIATED WITH THICKNESS

Despite the many advantages associated with increased thickness in telescopic solar panels, there are also inherent challenges that need consideration. The weight and bulk of thicker panels can complicate mobility and installation, especially for applications designed around portability. For instance, excessive thickness can limit the ease of extending and retracting the panels, which in turn may affect the operational efficiency of the deployed system.

Additionally, thicker panels may incur higher manufacturing costs, reflecting the increased amounts of material and energy required during production. This financial implication can be a turning point for consumers opting for portable or less-energy-intensive solutions. The balance between thickness and cost becomes a focal point, particularly in competitive markets where affordability and efficiency must be reconciled.

Ecological considerations also emerge, as the sustainability of sourcing materials for thicker panels must align with growing environmental concerns. Addressing the environmental footprint of production processes requires innovative design and manufacturing techniques that ensure the adoption of more sustainable materials continues to grow.

5. PERFORMANCE METRICS BASED ON THICKNESS

Evaluating the performance of telescopic solar panels brings into focus how thickness directly impacts key performance metrics. Efficiency ratings, durability assessments, and energy absorption capacities can reflect variances influenced by panel thickness. Manufacturers often publish these metrics, making comparisons essential for consumers looking for the optimal balance between versatility and performance.

Efficiency, often denoted as the ratio of energy output to solar energy input, shows marked differences between thick and thin panels under a range of conditions. Thicker designs may present higher efficiency rates due to the enhanced quality of materials used. Furthermore, testing conducted in varying temperature conditions can demonstrate how thickness influences performance; thicker panels generally retain operational stability better in extreme weather scenarios, underscoring their appeal for durable outdoor applications.

Conducting a holistic analysis of these variables serves consumers aiming to find tailored solutions that align with their energy needs and environmental conditions. By considering the performance variations based on thickness, users can make more informed choices regarding installation and long-term usage strategies.

6. TELESCOPIC SOLAR PANELS IN VARIOUS APPLICATIONS

Telescopic solar panels show versatility across multiple usage scenarios, from residential projects to industrial applications. In residential settings, homeowners are increasingly investing in these adaptable panels to optimize energy collection throughout the day. The retractable nature allows them to adjust their positioning based on sun exposure, amplifying energy collected during peak sunlight hours.

In commercial applications, telescopic panels are useful in fields like agriculture and tourism where mobile energy solutions contribute significantly to operational efficiency. These panels can be deployed in remote locations and retracted when not in use, maintaining a low profile and protecting investments from environmental risks.

Meanwhile, in military and disaster response scenarios, the flexibility of these solar solutions offers sustainable energy sources in challenging environments. Their portable and adjustable characteristics ensure a crucial power supply for operations without extensive infrastructure.

The adaptability associated with thickness in telescopic solar panels allows for tailored solutions conducive to diverse operational environments. This adaptability provides substantial opportunities for innovation and practical applications in renewable energy technology.

FAQs

1. WHAT MATERIALS ARE COMMONLY USED IN TELESCOPIC SOLAR PANELS?

The construction of telescopic solar panels typically involves prevalent materials such as monocrystalline and polycrystalline silicon, along with thin-film technologies. Monocrystalline panels, known for their high purity and efficiency, usually exhibit a thicker profile. This thickness ensures durability and reliability in fluctuating weather conditions. In contrast, polycrystalline panels present a slightly thinner design, balancing cost and energy efficiency, while thin-film panels offer lightweight flexibility. The choice of material directly influences not only the thickness but also performance metrics, such as energy conversion efficiency and longevity.

2. WHY DOES THE THICKNESS OF TELESCOPIC SOLAR PANELS MATTER?

The thickness of telescopic solar panels has essential implications for their durability and performance. Thicker panels typically withstand environmental stressors like high winds, temperature fluctuations, and physical impacts, making them more reliable in outdoor settings. Additionally, increased thickness often correlates with enhanced energy efficiency, as more silicon material can lead to better sunlight absorption. This characteristic is particularly important for users who rely on these panels for consistent energy needs, such as in off-grid alternatives or during outdoor events where solar optimization is critical.

3. HOW DOES THICKNESS AFFECT THE INSTALLATION OF TELESCOPIC SOLAR PANELS?

When considering installation, the thickness of telescopic solar panels can significantly impact both mobility and the associated infrastructure. Thicker panels can complicate carrying, extending, and retracting, especially in portable applications where weight becomes a limiting factor. Moreover, increased thickness may necessitate additional support structures to accommodate the added bulk, potentially increasing setup time and costs. On the other hand, thinner panels may offer enhanced mobility but can sometimes compromise durability, making it essential for consumers to assess which attributes best align with their intended usage scenarios for optimal performance and ease of handling.

The complexity surrounding the thickness of telescopic solar panels encompasses a myriad of factors affecting performance, durability, and application versatility. Thicker models, while often more efficient and durable, can complicate portability and introduce higher costs. In contrast, thinner alternatives provide flexibility but may lack the same resilience against environmental stressors. From understanding material selection to analyzing installation challenges, consumers must navigate these dynamics to make informed decisions that align with energy needs and operational environments. The interplay between thickness and functionality not only underscores the advancements in solar technology but also highlights the importance of thorough research and product comparison before investment decisions. Organizations and industries should prioritize careful evaluation of expected performance metrics, anticipated conditions, and overall requirements to optimize solar energy output effectively, ensuring sustainability and resilience in various applications.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-thick-is-the-telescopic-solar-panel/