To determine the amount of silicon required for solar panels, it can be stated that 1. An average crystalline silicon solar panel employs approximately 5-7 grams of silicon per watt of power output., 2. The necessary silicon quantity also depends on the solar cell’s efficiency and technology type., 3. Different solar technologies such as monocrystalline, polycrystalline, and thin-film each utilize varying amounts of silicon., 4. The overall environmental impact, including mining and processing silicon, necessitates careful consideration.

In particular, the 5-7 grams per watt metric is vital for understanding how to evaluate silicon needs for solar panel production. The efficiency level, as well as the specific technology being used, shapes how much silicon is integrated into a solar device. Full awareness of these elements enables manufacturers to optimize their designs and ultimately improve performance.

1. UNDERSTANDING SILICON’S ROLE IN SOLAR TECHNOLOGY

Silicon, a fundamental material in solar technology, is renowned for its unique properties that facilitate electricity generation. As a semiconductor, silicon allows for the effective conversion of sunlight into usable electrical energy. Its widespread availability and relative low cost positions it as the preferred material in the photovoltaic (PV) sector.

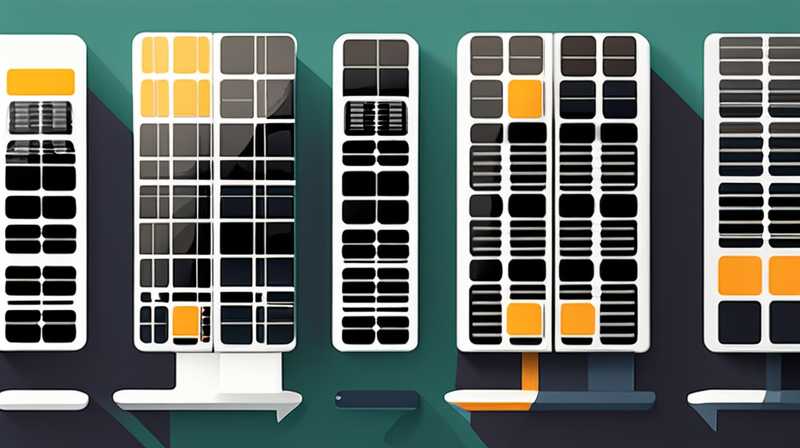

Different types of silicon-based solar cells are utilized in this realm, primarily including monocrystalline, polycrystalline, and thin-film variations. Monocrystalline panels offer higher efficiency rates and require purer silicon, whereas polycrystalline panels comprise silicon fragments and often yield slightly lower efficiency but at a more affordable cost. Thin-film technologies, on the other hand, employ minimal amounts of silicon and offer flexibility and lightweight configurations. Each category not only has individual performance metrics but also varying silicon consumption levels critical for production.

2. THE SIGNIFICANCE OF SILICON AMOUNT IN PANEL EFFICIENCY

The correlation between the amount of silicon and the efficiency of solar panels reflects ongoing innovations in the industry. Higher silicon purity generally results in improved conductivity and subsequent energy output. Consequently, subtle variations in the purity of silicon can dramatically alter the functional capacity of a panel, showcasing the need for precision in the preprocessing stage.

Moreover, high temperatures affect the efficiency metric; thus, the choice of silicon quality plays an essential role in moderating heat losses that can occur within the solar cells. R&D endeavors aim to enhance the performance of silicon by modifying its molecular structure and incorporating additional materials, ultimately seeking to drive down costs while amplifying energy conversion rates.

3. CALCULATING SILICON REQUIREMENTS FOR SOLAR MODULES

When producing solar panels, accurate calculations on silicon quantities become pivotal to ensure the balance between performance and economic viability. Monocrystalline solar cells, for instance, typically require around 120 grams of silicon per panel, translating effectively into the overall operational efficiency produced.

In contrast, polycrystalline cells, commanding a lower silicon footprint, usually approximate 80 grams per panel, classified under a different price point that attracts multiple market segments. Transitioning to thin-film solar technology, the silicon requirement drastically reduces, with some panels needing less than 30 grams of silicon for optimal performance without compromising the energy output significantly. This reduction highlights the ongoing trend to reduce the reliance on conventional silicon, in favor of alternative materials and technologies.

4. ENVIRONMENTAL AND ECONOMIC IMPACT OF SILICON USAGE

The environmental factors surrounding silicon production require meticulous consideration in modern solar initiatives. Mining silicon contributes to resource depletion and has been criticized for its ecological footprint. Countries engaged in silicon extraction must weigh the economic benefits against environmental sustainability concerns, particularly as solar demand rises.

In addition to environmental ramifications, the economic element cannot be disregarded. As manufacturers strive to optimize silicon usage, they must forecast market demands while ensuring that their silicon supply chains remain stable. It becomes a balancing act to stimulate growth and meet your environmental responsibilities as the solar market continues to expand rapidly.

5. RESEARCH AND ADVANCEMENTS IN SILICON TECHNOLOGY

Innovations in solar technology unveil exciting advancements regarding the utilization of silicon. Recent developments in bifacial solar cells, which collect light from both sides, have shown promising potential. These cells often function with less silicon compared to traditional options, yet provide increased energy generation capabilities by maximizing sun exposure.

Another area of exploration focuses on sustainable silicon production methods to simpler extraction processes that limit wastage and environmental strain. This could fundamentally alter the landscape of solar manufacturing, as the drive for sustainability grows stronger globally. The continuous push for enhanced R&D and novel applications illustrates the active strides being taken in the silicon solar sector, with further insights anticipated as the industry evolves.

COMMONLY ASKED QUESTIONS

WHAT IS THE AVERAGE SILICON CONTENT PER SOLAR PANEL?

On average, a typical crystalline silicon solar panel contains around 120 grams for monocrystalline and 80 grams for polycrystalline types. However, thin-film technologies have dramatically reduced silicon requirements to below 30 grams. The differences in silicon content largely depend on the efficiency outcomes and manufacturing processes employed by producers, combining price quality into their designs. Variations in the manufacturing technique play a significant role in defining silicon’s consumption per solar module and the overall performance parameters.

HOW DOES SILICON PURITY AFFECT SOLAR PANEL PERFORMANCE?

Silicon purity is a critical factor affecting solar panel performance. Higher purity levels correlate directly with increased conductivity, which ultimately translates to enhanced energy efficiency. Even slight modifications in purity can lead to notable discrepancies in how well a panel functions under various conditions. The industry continuously strives to refine silicon quality as it directly impacts energy yield, longevity, and cost-effectiveness, leading to investments aimed at improving manufacturing processes.

WHAT ARE THE ENVIRONMENTAL IMPLICATIONS OF SILICON EXTRACTION?

The extraction of silicon from natural resources can result in significant environmental consequences, including ecosystem disruptions and resource depletion. Mining practices often lead to habitat destruction and pollution of surrounding environments, necessitating more stringent regulations and sustainable practices in silicon production. Addressing the ecological concerns is essential as the solar industry seeks to expand, prompting further advancements in both operational techniques and technological innovation that aim to mitigate the overall environmental impact.

The importance of silicon in solar panel production cannot be overlooked, as it forms the backbone for solar technology. The quantity of silicon required for various types of solar panels significantly affects their efficiency, cost, and environmental impact. Over the years, industry advancements have demonstrated a marked improvement in the use of silicon, aligning with the global shift towards sustainable energy solutions. With monocrystalline and polycrystalline panels continuing to dominate the market, the nuances in silicon requirements for each must be carefully analyzed, while innovations in materials like thin-film promise further reductions in silicon reliance. Furthermore, addressing the environmental concerns associated with silicon extraction remains a pressing need. Through ongoing research and development, the industry may achieve sustainable production practices alongside enhanced silicon utilization, ultimately leading to a more robust solar energy framework. As solar technology continues to evolve, understanding the dynamics of silicon usage becomes increasingly crucial, ultimately contributing to a cleaner energy future.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-much-silicon-is-needed-for-solar-panels/