The operation and maintenance fee of an energy storage power station can vary significantly based on several factors. 1. Costs can range from $20 to $40 per kilowatt per year, depending on the technology and infrastructure in place. 2. The distribution of these costs falls under several categories such as regular maintenance, emergency repairs, and operational staffing. 3. Another crucial aspect is the type of energy storage technology employed, which can affect both initial and ongoing expenditures. To elaborate, 4. Advanced battery systems may require higher upfront investment but can lead to lower long-term operational costs due to enhanced efficiency and reduced maintenance frequency.

1. UNDERSTANDING ENERGY STORAGE POWER STATIONS

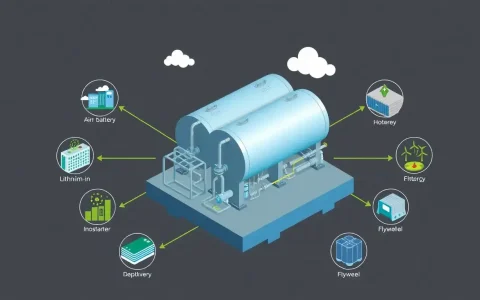

Energy storage power stations play a pivotal role in modern electrical grids by acting as buffers against intermittency and aiding in grid stability. The fundamental objective of these facilities is to harness energy during periods of surplus, especially from renewable sources such as solar and wind, and release it when demand peaks. Such functionality makes them essential in mitigating the fluctuations inherent in renewable energy production.

However, the costs associated with these infrastructures are not negligible and warrant thorough examination. The operation and maintenance expenses are crucial for assessing their viability and long-term sustainability. This overview delves deeply into various elements contributing to the overall financial outlay required to operate these facilities effectively.

Effective management and oversight of energy storage systems are imperative to ensure optimal performance and longevity. Various factors contribute to the overarching operation and maintenance costs, including technology choices, geographical placement, usage intensity, and economic conditions.

2. CATEGORIES OF OPERATION AND MAINTENANCE FEES

The costs associated with operating and maintaining energy storage facilities can be broadly classified into several categories. Each category has its specific components that contribute to the overall financial landscape of energy storage power stations.

2.1. REGULAR MAINTENANCE COSTS

Regular maintenance entails systematic inspections, routine service, and preventative measures designed to enhance the longevity and reliability of the energy storage system. 1. These preventative measures are crucial for avoiding larger, often costlier repairs down the line. 2. On average, maintenance costs can constitute approximately 70% of the total operation expenses.

Furthermore, the frequency and intensity of maintenance activities are influenced heavily by the technology employed. 1. For example, lithium-ion battery systems generally require less frequent maintenance compared to traditional lead-acid batteries. This aspect underscores the significance of selecting appropriate technologies aligned with operational requirements.

Another consideration within regular maintenance is the labor costs associated with skilled personnel. 1. High-level expertise is often required to manage complex systems effectively, contributing to the overall expenditure. 2. Training and safety protocols also add layers of financial commitment, further justifying the need for skilled operators.

2.2. EMERGENCY REPAIRS

Emergency repairs represent another crucial segment of the operational budget. Despite meticulous planning and maintenance, unforeseen circumstances can still necessitate immediate interventions. 1. These events can range from system malfunctions, extreme weather effects, or unexpected operational demands. 2. The financial impacts of these repairs can rapidly escalate if systems are not equipped with robust contingency plans.

It is essential to conduct a thorough risk assessment to predict potential failure points and allocate resources accordingly. 1. Investing in methodologies such as predictive maintenance can reduce the frequency of emergency repairs. 2. Additionally, implementing redundant systems can avert complete system failures—alleviating costs associated with prolonged outages.

3. TECHNOLOGICAL INFLUENCES ON OPERATION COSTS

The chosen energy storage technology greatly impacts the ongoing expenses incurred during operation and maintenance. With numerous technologies available, from lithium-ion batteries to pumped hydro storage, 1. understanding the nuances of each is critical for optimizing costs.

3.1. LITHIUM-ION TECHNOLOGY

Lithium-ion batteries are widely revered for their high energy density and efficiency; however, they do come with high initial costs. 1. The operational lifespan of lithium-ion batteries is typically longer than some of their counterparts, offering potential long-term savings despite an elevated upfront expenditure. 2. Maintenance for these systems tends to involve software updates and battery health assessments, which, while present, can be less intensive than for other battery types.

Moreover, 1. advancements in recycling methods for lithium-ion technology are paving the way for decreased long-term operational costs. As more efficient recycling processes develop, the initial investments in material extraction and battery production can see a significant decline.

3.2. PUMPED HYDRO STORAGE

Pumped hydro storage, while less flexible than other technologies, offers distinct advantages in terms of operational costs. 1. This system’s low maintenance requirements considerably reduce annual operational expenses compared to battery-based systems. 2. The structure itself often enjoys a longer lifespan; therefore, the yearly costs associated with operation per kilowatt can be significantly lower.

However, the geographical limitations of pumped hydro mean that initial capital requirements can be substantial due to site acquisition and infrastructure development. 1. Furthermore, unexpected geological challenges may inflate overall project costs. Balancing these factors carefully is vital in any long-term feasibility study.

4. REGIONAL FACTORS AND MARKET INFLUENCES

Regional characteristics and market dynamics also drastically influence the operation and maintenance cost structure of energy storage power stations.

4.1. GEOGRAPHICAL INFLUENCES

The physical location of a storage facility plays a crucial role in determining both operational efficiency and cost-feasibility. 1. Regions with stringent regulations may see higher compliance costs, while those offering incentives—like tax breaks or grants—might lessen financial burdens. 2. Additionally, local climate conditions factor into operational lifespan; areas prone to extreme temperatures may experience accelerated aging of batteries.

Logistical variables such as proximity to required resources and transportation networks can also affect expenses. 1. Facilities situated near urban centers may incur greater costs due to land acquisition but benefit from shorter transmission distances to customers. 2. On the contrary, rural installations may secure cheaper land but contend with challenges in resource access and operational management.

4.2. ECONOMIC VARIABLES

Overall economic conditions also hold substantial sway over operation and maintenance expenditures. 1. Ranging from fluctuating labor costs to variable prices for materials, each factor must be monitored diligently. 2. Additionally, changes in regulatory frameworks and energy pricing can profoundly impact the financial sustainability of energy storage projects.

Furthermore, market demand for energy resources can shift dynamically, affecting operational strategies. 1. A sudden increase in demand can require rapid adjustments in storage operations, incurring higher costs associated with scaling up. 2. Conversely, periods of low demand necessitate careful management of resources to avoid surplus energy that could lead to financial loss.

FAQs

WHAT ARE THE MAIN COMPONENTS OF OPERATION AND MAINTENANCE COSTS FOR ENERGY STORAGE POWER STATIONS?

The primary components of operation and maintenance expenses for energy storage facilities include regular maintenance, emergency repairs, staffing, and technological expenses. Regular maintenance encompasses routine system checks, component replacements, and preventative measures to enhance system reliability and longevity. Emergency repairs account for unforeseen malfunctions requiring immediate fixed costs, which can escalate depending on the severity of the issue. Labor costs associated with skilled technicians and operational staff are vital, particularly in complex systems requiring specialized knowledge. Furthermore, technological expenses vary based on the type of energy storage employed, influencing both initial investments and ongoing maintenance requirements. Understanding these components equips stakeholders with critical insights into the potential financial landscape surrounding energy storage operations.

HOW DOES TECHNOLOGY AFFECT OPERATION COSTS IN ENERGY STORAGE POWER STATIONS?

Technological choices significantly influence operational costs in energy storage facilities. Different energy storage types, such as lithium-ion batteries and pumped hydro systems, come with varying maintenance requirements, efficiencies, and lifespan variables. For instance, lithium-ion batteries, while often having elevated upfront expenses, typically exhibit lower maintenance demands due to fewer mechanical components compared to traditional systems. In contrast, pumped hydro may entail more initial capital investment but often results in lower ongoing operational expenses due to extended lifespans and less frequent maintenance needs. Ultimately, careful selection of technology aligned with project goals can enhance both financial and operational viability.

HOW CAN OPERATION AND MAINTENANCE COSTS BE OPTIMIZED IN ENERGY STORAGE POWER STATIONS?

Optimization of operation and maintenance costs in energy storage facilities can be achieved through several strategies. Primarily, implementing predictive maintenance techniques allows for the early identification of equipment issues, thus reducing reliance on costly emergency repairs. Additionally, training personnel in best operational practices ensures higher efficiency and performance, leading to minimized waste and downtime. The adoption of advanced monitoring systems aids in tracking system performance, driving informed decision-making for resource allocation and operational adjustments. Moreover, selecting cost-effective components and leveraging economies of scale during initial setup can further decrease ongoing expenses. Strategic planning and conscious decision-making are crucial for success in managing costs effectively.

The operation and maintenance expenses associated with energy storage power stations constitute a complex landscape of financial commitments imperative for the successful execution of such ventures. By dissecting the myriad components that contribute to these costs—ranging from technological influences to regional variables—stakeholders can genuinely appreciate the importance of careful planning and strategic decision-making. A keen understanding of the various aspects that inform operation and maintenance expenditures ultimately allows for better resource allocation, enhanced efficiency, and increased return on investment. As the energy landscape continues to evolve, investing in robust infrastructure paired with prudent operational strategies paves the way toward sustainable and economically viable energy storage solutions. Addressing these nuances diligently ensures that energy storage power stations not only fulfill their critical grid support roles but do so in a financially responsible and impactful manner. The foresight exercised today will undoubtedly dictate the energy storage industry’s path toward greater integration and innovation in the years to come.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-much-is-the-operation-and-maintenance-fee-of-energy-storage-power-station/