Liquid cooling energy storage systems are increasingly explored as alternatives to conventional energy storage methods, offering efficiency and sustainability benefits. 1. The cost of liquid cooling energy storage systems can significantly vary, typically ranging from $100 to $800 per kilowatt-hour, depending on multiple factors. 2. Upfront installation expenses are influenced by technology selection, infrastructure, and scale. 3. Operating and maintenance expenses must also be factored in to understand the total lifecycle cost. 4. Comparing these costs to conventional systems highlights both economic viability and operational advantages.

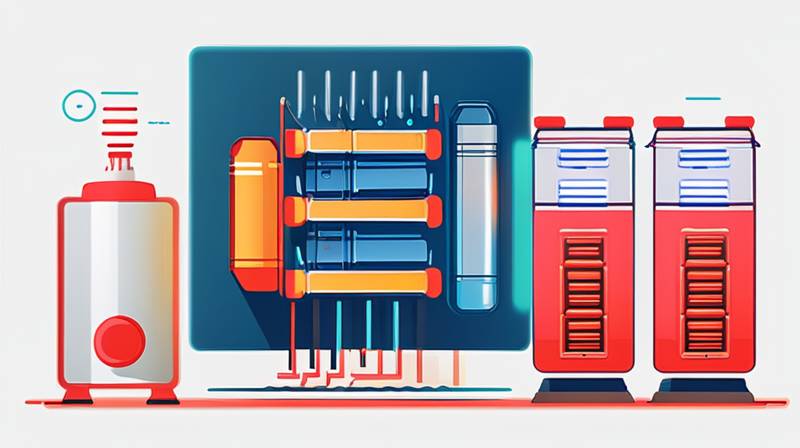

Liquid cooling represents a remarkable shift in energy storage technologies, tapping into the efficiencies of thermal energy retention and distribution. Typically, this method uses a coolant to absorb and transfer heat, making it proficient in managing environments for batteries and other energy components. The architecture of such systems inherently fosters a longer lifecycle and reduced degradation rates. Understanding the financial implications of implementing liquid cooling technology requires a multifaceted examination, including initial investment and subsequent operational expenditures.

1. INITIAL INVESTMENT COSTS

In embarking on the journey to establish liquid cooling energy storage, the initial investment merits considerable attention. Infrastructure, technology, and scale are pivotal determinants influencing costs.

The foundation of cost assessment lies within the selection of technology. Various liquid cooling systems exist, ranging from traditional chilled water systems to advanced phase-change materials, each carrying distinct price tags. High-performance systems might come with higher tooling and equipment costs due to enhanced materials and sophisticated designs. Further complexity arises when determining the necessary infrastructure conducive to a liquid cooling setup. Facilities may require substantial upgrades to accommodate these systems, significantly impacting capital expenditure.

Another salient factor is the scale of implementation. Large-scale installations typically benefit from economies of scale, resulting in lower per-kilowatt-hour costs. Conversely, smaller deployments may struggle to mindfully distribute fixed costs across a limited kWh capacity, leading to a heightened cost perception on a per-unit basis. Such considerations encourage stakeholders to conduct thorough financial mapping to ascertain true investment burdens.

2. INSTALLATION EXPENDITURES

Delving deeper into costs, installation expenditures emerge as a critical component. Labor costs associated with skilled technicians for system setup can fluctuate based on regional wages and technical expertise. Specialized knowledge is often requisite to effectively integrate cooling systems with existing energy storage arrays.

Additionally, logistical factors play a role in installation expenditures. Transportation of materials, whether local or international, can incur significant charges, especially if specialized components are necessitated. Moreover, unforeseen environmental conditions may require supplementary measures, which can inflate installation costs. Obtaining accurate estimates through detailed project planning mitigates potential fiscal uncertainties encountered during setup.

3. OPERATIONAL EXPENSES

While initial costs are paramount to project feasibility, operational expenses remain crucial for long-term sustainability. Liquid cooling systems, although efficient, do incur ongoing costs related to energy usage, maintenance, and potential upgrades. Evaluating the energy demand for circulation pumps and chillers becomes essential, particularly in regions with variable electricity rates.

Regular maintenance, pivotal for system longevity, also introduces recurring costs. Aspects such as coolant replacement, system inspections, and potential repairs demand proactive budgeting. Performing preventive measures not only ensures operational efficiency but also forestalls significant repair expenses over time. Ensuring a holistic understanding of operational expenses facilitates stronger financial planning and project viability.

4. COMPARATIVE ANALYSIS WITH CONVENTIONAL SYSTEMS

Gaining comprehension of liquid cooling energy storage costs becomes clearer through comparative analysis against traditional models. Standard energy storage solutions, like lithium-ion batteries, reveal distinct cost structures, offering further financial insight.

Traditional systems often present lower upfront costs, yet their operational longevity and efficiency may prove lacking in the long run, translating into higher cumulative costs per usable kilowatt-hour. Liquid cooling systems, with their sustained performance and reduced degradation rates, often afford superior value despite higher initial investment. Comparing lifecycle expenses demonstrates the potential for enhanced return on investment.

Moreover, the agility of liquid cooling technology can provide an edge in rapidly changing energy markets. As renewable energy sources become more prominent, the need for effective storage solutions intensifies, prompting innovation. The adaptability and efficiency of liquid cooling align seamlessly with this evolutionary trajectory. As energy demands continue to escalate, the importance of adopting efficient methodologies remains critical.

5. LONG-TERM ECONOMIC BENEFITS

In investigating long-term economic benefits, stakeholders must recognize the overall cost-effectiveness liquid cooling conveys. Deployment of these systems frequently results in decreased energy expenditures, prolonging asset life and sustainable returns. Cost savings emerge through lower maintenance demands and more efficient operational practices, enhancing both cash flow and profitability.

Furthermore, the quantitative value derived from liquid cooling’s thermal management abilities cannot be overstated. Effectively controlling temperatures reduces wear on energy storage systems, allowing for an extended operational lifespan. Consequently, the economic consequences over time become increasingly favorable. Evaluating these extended periods affirms the robust nature of liquid cooling technology and its successful adaptation for future energy storage demands.

FREQUENTLY ASKED QUESTIONS

WHAT FACTORS INFLUENCE THE COST OF LIQUID COOLING ENERGY STORAGE SYSTEMS?

The cost of liquid cooling energy storage systems is influenced primarily by several interconnected factors. Technology selection plays a significant role; different liquid cooling configurations have varying pricing structures. For instance, advanced systems utilizing phase-change materials tend to cost more upfront compared to traditional methods due to the sophistication involved. Infrastructure requirements are also a critical consideration; existing facilities may need significant upgrades for compatibility, introducing additional costs. Scale of implementation is another factor; larger projects typically enjoy lower costs per kilowatt-hour due to economies of scale, whereas smaller implementations often face higher costs relative to capacity. Lastly, regional labor costs can affect installation expenses, requiring skilled professionals for effective system setup and maintenance.

HOW DO OPERATIONAL EXPENSES OF LIQUID COOLING SYSTEMS COMPARE TO TRADITIONAL ENERGY STORAGE?

Operational expenses for liquid cooling systems can vary but often present lower long-term costs when compared to traditional energy storage systems. Conventional models, such as lithium-ion batteries, may have lower upfront costs, yet their operational efficiency can degrade more rapidly, leading to higher cumulative expenses over time. Liquid cooling systems are designed for efficiency; their energy consumption for circulation pumps and chillers can be offset against the superior longevity and lower maintenance requirements they offer. As such, while they may have higher initial operating demands, their sustained performance ultimately yields cost savings and value over their full lifecycle. Through careful financial analysis, stakeholders can identify long-term operational savings, validating the economic rationale for investment.

ARE LIQUID COOLING ENERGY STORAGE SYSTEMS ECONOMICALLY VIABLE FOR SMALLER PROJECTS?

The economic viability of liquid cooling energy storage systems for smaller projects warrants careful examination. While larger deployments generally benefit from economies of scale, smaller installations can encounter higher costs per kilowatt-hour. These higher relative costs stem from the fixed expenses associated with system installation and maintenance, which may not diminish significantly with reduced capacity. However, smaller projects may also benefit from tailored financing arrangements and incentive programs that support innovative energy storage solutions. Investigating local regulations, potential subsidies, and overall community demand for sustainable practices can foster greater financial viability for smaller-scale implementations. As interest in renewable energy grows, smaller projects that embrace liquid cooling may not only find economic realization but also contribute to broader sustainability goals.

SIGNIFICANCE OF LONG-TERM FINANCIAL PLANNING

In navigating the complex world of energy storage, long-term financial planning plays a pivotal role in deducing the ultimate feasibility of liquid cooling systems. Establishing robust forecasting capabilities allows project managers and stakeholders to grasp the full scope of expenditures across the operational lifecycle. Comprehensive analysis of both initial investments and ongoing costs provides stakeholders with valuable insights for informed decision-making. Ensuring an evolving understanding of changing energy markets, regulatory impacts, and technological advances culminates in enhanced project strategies. Emphasizing the impactful nature of detailed financial planning will enable effective implementation of liquid cooling energy storage systems, ensuring sustainable energy solutions for the future.

The exploration of the costs associated with liquid cooling energy storage systems unveils both challenges and opportunities. A focused examination on costs highlights the multifaceted nature of the investment, which encompasses initial expenses, installation, operational sustainability, and long-term economic benefits. Such systems promise increased efficiency and reduced degradation compared to conventional models, affirming their potential viability in a rapidly evolving energy landscape. Comprehensive understanding leads to better decision-making, while methodical financial planning ultimately assures the success of implementing these pioneering energy storage solutions.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-much-does-liquid-cooling-energy-storage-cost/