Moving a machine using solar energy incurs various costs that can vary widely based on several factors. 1. The distance of the move significantly influences expenses, as longer distances typically require more resources. 2. Equipment specifications, including size and weight, also affect logistical needs and costs. 3. Labor costs must be considered depending on local rates and the complexity of the move. 4. Installation of solar panels might represent an upfront expenditure, but it can lead to savings over time. 5. Consideration for maintenance and potential unforeseen expenses is essential for a thorough assessment. The integration of solar energy into the machinery transport process not only adds a sustainable dimension but can also lead to long-term financial benefits if executed correctly.

1. UNDERSTANDING MACHINE MOVEMENT COSTS

Engaging in the relocation of heavy machinery represents a significant logistics challenge that entails diverse financial considerations. Each move can demand specific resources that might necessitate an investment of time, labor, and logistical elements tailored to the unique characteristics of the machinery itself. Factors influencing costs include transportation distances, the nature of the machine, and regional labor market variations. By comprehensively analyzing each aspect, stakeholders can develop a more informed perspective on expenditure and savings opportunities.

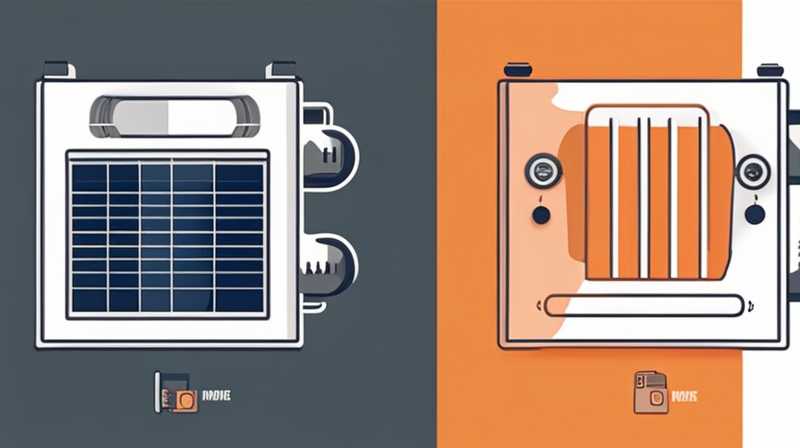

Additionally, when addressing moving machinery, it is essential to evaluate the particular requirements of solar energy applicability. Solar energy systems can range in size and complexity, thus impacting the overall transport infrastructure required. The integration of solar technology, while potentially expensive at first, can yield substantial savings on energy usage. Understanding the costs associated with both moving machinery and appropriate solar implementation will enable individuals and organizations to formulate an efficient budget.

2. DISTANCE AND TRANSPORTATION

The role of distance in machinery relocation is a vital component of overall costs, significantly influencing logistics efficiency as well as budgetary allocations. Long-distance moves impose additional challenges that can escalate expenses, such as fuel consumption, permits, and accommodation stops for transporting equipment. When machinery is relocated over great distances, the need for coordinated logistics often grows, which can further amplify operational costs.

Another consideration linked with distance relates to the environmental impact of transportation methods. Utilizing solar energy can mitigate some of the adverse effects associated with traditional fuel sources when planning large-scale machinery moves. By investing in solar-powered vehicles, businesses might find you can significantly curtail fuel costs over time, although the initial implementation creates an upfront expenditure. Striking a balance between efficient distance planning and sustainable practices can lead to long-term benefits, ultimately resulting in lower expenditure moving machinery while making strides towards environmental responsibility.

3. EQUIPMENT SPECIFICATIONS

The specifications surrounding machinery relocation can range broadly and critically influence costs. Factors such as weight, dimensions, and operational functionality are paramount when considering logistical resources. Bulkier and heavier machines often necessitate specialized transport methods and might involve routes with strict compliance regulations. Furthermore, regulatory constraints may dictate how certain types of machinery can be moved, impacting expenses as well.

Another aspect to consider involves the nature of the machinery itself. Different types of machines may require additional handling and protection during the transport process, which can incur extra costs. Specialized packing materials, lifting equipment, and secure storage are essential for minimizing risks inherent to moving delicate or expensive equipment. Prioritizing careful planning and consideration based on the unique requirements of the machinery being relocated allows organizations to avoid unexpected costs linked with damage or inefficiency during the move.

4. LABOR COSTS

Labor represents a considerable portion of machinery relocation expenses, influenced by local market conditions, skill requirements, and duration of the moving process. Engaging skilled labor ensures that the equipment is handled properly, minimizing risks of damage, which can lead to both increased costs and impaired productivity. The complexity of moving specific machinery types may also necessitate hiring specialized personnel, further impacting the financial landscape.

Additionally, labor costs can fluctuate depending on the time of year and regional economic conditions. Seasonal demand often affects the availability of skilled labor, leading companies to potentially incur higher expenses during peak periods. For organizations planning moves involving solar energy, it may be feasible to incorporate training or educational measures for existing staff, leveraging their insights into solar technology to maintain forward-thinking practices long-term. Such strategies represent proactive steps in budgeting that can yield significant savings over time.

5. INSTALLATION AND IMPLEMENTATION OF SOLAR ENERGY

Incorporating solar energy into the machinery moving process encompasses potential upfront investments, alongside manageable long-term savings. The purchase of solar panels can significantly impact initial budgeting but can notably reduce operating costs for machinery over time. Evaluating how best to implement solar solutions involves choosing the appropriate technology to ensure efficiency and longevity while considering compatibility with existing systems.

Furthermore, organizations keen on utilizing solar energy should also consider integrating maintenance contracts to ensure sustained performance of solar installations. Scheduled maintenance reduces the likelihood of unexpected costs arising from system failures, which can be detrimental in both moving machinery and adhering to long-term financial plans. The initial expense may indeed be considerable depending on organizational scope, yet intelligent implementation can translate to significant returns on investment through reduced energy costs and increased operational reliability.

6. MAINTENANCE AND UNCERTAINTIES

After relocating machines, ongoing maintenance becomes a pivotal aspect of the operational framework. Budgeting for upkeep ensures that machinery remains compliant with regulations and operates at maximum efficiency. Including provisions for regular inspections, tune-ups, and repairs can prolong the lifespan of both the machinery and solar energy systems, preventing costly breakdowns and ensuring uninterrupted operations.

Unforeseen expenses can emerge in the machinery moving process, necessitating a budgeting approach that embraces flexibility. Allocating a portion of the budget for potential emergencies or unforeseen circumstances mitigates the risk of disruptions impacting overall business operations. Adapting financial plans to account for uncertainties also sustains a robust operational model that supports continued growth amid changing market conditions. By judiciously planning in advance, stakeholders can navigate unexpected challenges while maintaining focus on strategic objectives.

FAQs

HOW DOES DISTANCE AFFECT THE COST OF MOVING MACHINERY WITH SOLAR ENERGY?

The distance of machinery transportation plays a critical role in determining overall expenses. When relocating machinery over extended distances, costs tend to rise significantly due to increased fuel consumption, labor hours, and potential permits required for travel through specific regions. Furthermore, longer transport times necessitate additional logistical considerations, which can lead to expenses related to lodging and food for crew members. Shifting to solar energy can help mitigate some of these challenges by utilizing solar-powered transportation solutions, which diminish dependence on conventional fuel sources. By combining solar technology with strategic planning, businesses can potentially reduce costs linked to distance while embracing sustainable practices.

WHAT MACHINERY TYPES ARE MOST EXPENSIVE TO MOVE AND WHY?

Certain machinery types incur higher moving costs due to their weight, dimensions, and intricacies involved in transport. Heavier equipment often demands specialized transportation solutions as well as additional safety measures. Complex machinery may require specialized handling that involves expert labor skilled in assembling or disassembling items based on the machine’s requirements. Moreover, sensitive machinery involving intricate components is more prone to damage during transport, which necessitates advanced packing materials and precautionary measures to safeguard against unexpected disruptions. Hence, companies should perform thorough assessments of machinery types before executing moves to adequately plan for potential expenses.

WHAT ARE THE LONG-TERM BENEFITS OF USING SOLAR ENERGY FOR MACHINE MOVING?

Integrating solar energy into machinery moving operations creates several long-term advantages that can significantly impact overall expenditure and operational efficiency. Utilizing solar-powered transport solutions can decrease fuel costs and enhance sustainability, allowing businesses to prioritize eco-friendly practices that resonate with contemporary consumer values. Additionally, the initial investment in solar technology often leads to substantial savings in energy expenses over time. Maintenance contracts for solar systems may also optimize energy efficiency and avoid costly repairs. Balancing efficiency and adaptability enables organizations to maximize returns on investment while contributing to environmental sustainability in the long run.

Utilizing solar energy for machine movement encompasses a variety of costs influenced by numerous factors, including distance, equipment specifications, and labor requirements. In assessing these expenses, organizations can devise a more strategic budget approach that embraces sustainability while aligning with operational goals. Understanding these dynamics empowers stakeholders to implement informed decisions that foster both immediate and long-term benefits, blending traditional moving logistics with innovative solar solutions. By effectively integrating both aspects, companies can navigate the complexities of mobility and sustainability, paving the way for efficient, cost-effective operations in the machinery industry. Each layer of consideration amplifies the approaches available to ensure successful machinery relocation, especially when harmonizing with solar energy solutions, ultimately enhancing both financial viability and environmental responsibility in their operations.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-much-does-it-cost-to-move-a-machine-with-solar-energy/