1. The cost of energy storage battery testing can fluctuate significantly based on various factors, including scale, battery technology, service complexity, and geographical location. 2. On average, testing services can range from $200 to $2,000, with sophisticated tests potentially going beyond $5,000. 3. Testing processes encompass a variety of evaluations such as performance, capacity, and safety assessments. 4. Detailed analysis regarding the specific requirements of testing can greatly influence the total cost incurred.

ENERGY STORAGE BATTERY TESTING: AN EXPANDED EXAMINATION

1. INTRODUCTION TO ENERGY STORAGE BATTERY TESTING

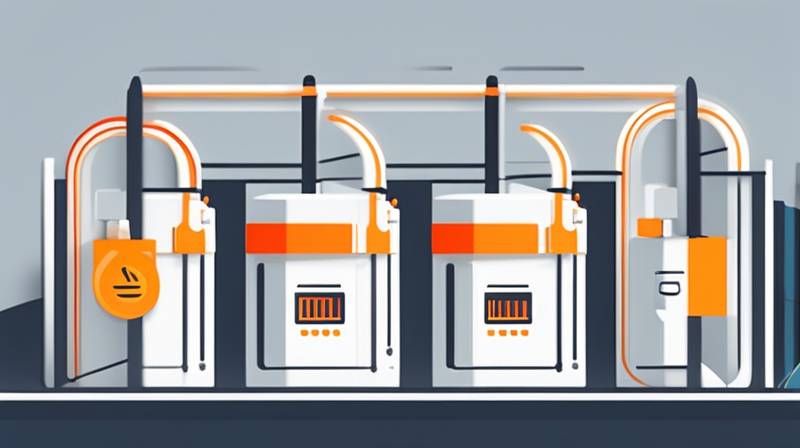

The necessity for energy storage systems has surged, driven by an insatiable demand for sustainable and reliable power sources. Energy storage batteries play an essential role in balancing supply and demand, ensuring that power generated from renewable resources is efficiently utilized. With the growing complexities of various battery chemistries and applications, the importance of thorough battery testing becomes evident. This rigorous examination serves to ensure that batteries meet specified standards and perform reliably in real-world scenarios.

Testing not only affirms the viability of the battery system but also guarantees safety measures are adhered to, protecting end-users and equipment from potential hazards. Various testing methodologies exist, each tailored to assess different attributes of the battery, including capacity, longevity, and safety, contributing to the overall reliability of energy storage solutions.

In addition to adherence to safety and performance standards, well-executed energy storage battery testing fosters overall investment confidence, whether in individual applications or large-scale installations. Regulatory frameworks also play a significant role in establishing testing protocols, ensuring that the batteries used adhere to stringent requirements.

2. FACTORS INFLUENCING TESTING COSTS

2.1 TYPE OF BATTERY TECHNOLOGY

The kind of technology utilized in energy storage batteries significantly impacts the overall testing expenses. Different chemistries—such as lithium-ion, lead-acid, or flow batteries—have distinct characteristics, which necessitate unique methodologies for testing.

Lithium-ion batteries, widely recognized for their efficiency and energy density, require specific assessments for performance and thermal stability, which might incur additional costs compared to other technologies. For instance, extensive cycle life testing involves numerous charge and discharge cycles to ascertain longevity, thus leading to elevated costs. On the other hand, lead-acid batteries, while less expensive to test, require thorough scrutiny of parameters such as state of charge and sulfation effects.

The testing procedures may also be influenced by the intended application of the batteries, whether for renewable energy integration, grid support, or electric vehicles. Specialized tests aimed at these applications may increase costs due to the necessity for customized protocols.

2.2 SCALE OF TESTING

The volume of batteries under examination plays a crucial role in determining costs as well. Batch testing often presents a more economical option, reducing the per-unit expense. Conversely, individual thorough evaluations for a large number of batteries can become exponentially more expensive due to the fixed costs of equipment and labor associated with the process.

In commercial settings, testing regimes are often adopted for entire energy storage systems rather than single components. Comprehensive evaluations of a battery system may involve performance validation under varying conditions, requiring extensive time and labor.

Furthermore, companies may opt for long-term testing regimes, assessing systems over months or even years. This enduring approach gathers valuable data but requires a decisive commitment regarding budget allocation.

3. TESTING PROCESSES AND METHODOLOGIES

3.1 PERFORMANCE TESTING

Determining the performance capabilities of an energy storage battery is paramount. This category of testing primarily focuses on the ingestion and release of energy, efficiency rates, and the ability to maintain performance under various operational scenarios.

Standards set by organizations such as the International Electrotechnical Commission (IEC) provide a benchmark for performance assessments. Tests often involve measuring cycle efficiency, charge/discharge rates, and self-discharge levels. Each aspect aims to affirm that the battery delivers reliable performance throughout its operational life. The costs associated with performance testing can vary drastically based on the required comprehensiveness and the underlying technology.

Long-term performance assessments may extend over several months, taking into account environmental influences such as temperature and humidity, ultimately adding to the overall testing expense.

3.2 CAPACITY TESTING

With energy storage devices, capacity testing is crucial. This testing verifies that a battery can hold a specified amount of energy, a factor influencing the overall performance profile. Establishing capacity reliability is vital for applications requiring specific energy thresholds.

In conducting capacity tests, scenarios simulating real-life operational conditions are examined, determining how much energy can consistently be delivered over various cycles. This may involve extensive charge/discharge testing until battery voltage drops to a predetermined cutoff.

The complexities involved with capacity testing, particularly in large-scale deployments, directly correlate to the associated costs. Thorough evaluations with minimal variations may attract higher pricing as a result of their technical demands.

4. REGULATIONS AND CERTIFICATIONS AFFECTING TESTING COSTS

4.1 COMPLIANCE STANDARDS

Energy storage battery testing must align with compliance standards established by regulatory agencies. Significant governing bodies such as Underwriters Laboratories (UL) and the IEC mandate specific testing requirements to promote safety and efficiency within the industry. Noncompliance can lead to potential risks associated with user safety and could entail further expenditures for rectification.

Different markets may impose varying regulatory requirements, necessitating tailored testing procedures based on both local and international guidelines. Costs can increase based on the necessity to meet these multifaceted regulations, with some tests potentially involving third-party verification services, further elevating expenses.

Budgeting for regulatory compliance should always anticipate potential costs arising from repeat evaluations or further testing required for product approval.

4.2 CERTIFICATION EXPENSES

Acquiring necessary certifications post-testing is often a vital phase in the process, influencing total expenditures. Certification entails rigorous examinations confirming that a battery complies with performance, safety, and environmental standards.

The journey to obtaining documentation for certification may encompass multiple tests, administrative processes, and fees; ultimately driving costs higher. Furthermore, the duration to achieve certification can stretch over several weeks, particularly for high-capacity modular systems, providing a variable cost allocation for testing and approval.

Ultimately, the necessity for certification should not be overlooked, as it often becomes integral in selling or utilizing battery technology within various applications.

5. ADDITIONAL CONSIDERATIONS

5.1 LOCATION AND LAB CAPACITY

The testing location significantly influences the overall financial outlay. Laboratories capable of executing thorough evaluations may express variations in pricing based on factors like rental costs, labor expenses, and operational overheads accumulated in different regions. Consequently, facilities situated in metropolitan areas generally propose elevated pricing structures due to an increased cost of doing business.

In addition, advanced laboratory capabilities affect pricing structures. Facilities equipped with sophisticated testing instruments position themselves to deliver more intricate assessments; such enhanced offerings often come with higher price tags.

5.2 VALUE OF TESTING

While the initial financial outlay associated with energy storage battery testing may pose a challenge for some operators, the associated benefits can justify expenses. Robust testing guarantees longevity, efficiency, and safety, ultimately translating into reduced maintenance costs and increased confidence in system reliance.

Investing in comprehensive testing can mitigate risks associated with battery failure, safeguarding investments and supporting sustainability goals. Ensuring a reliable return on investment over time typically leads to significant benefits that far exceed initial costs.

In the fast-evolving sphere of energy storage, allocating resources for exhaustive testing is imperative to harness the full capacity of advanced battery technologies.

COMMONLY ASKED QUESTIONS

WHAT ARE THE COMMON TYPES OF BATTERY TESTING?

Several testing types are employed to ensure batteries operate effectively and safely. Notably, performance, capacity, cycle-life, and thermal testing method are prevalent. Performance testing evaluates how batteries behave under specified conditions; capacity testing measures how much energy a battery can store; cycle-life testing examines the longevity of a battery through multiple charging and discharging cycles; while thermal testing ascertains how a battery performs under varying temperature conditions. These tests collectively ensure that batteries deliver optimal and safe performance across their intended lifecycle.

HOW LONG DOES BATTERY TESTING TAKE?

The duration of testing can vary widely based on the type and complexity of the tests being conducted. Simple performance checks may take a few hours, whereas thorough capacity assessments can extend over several days. Long-term testing, especially for lifecycle aspirations, often spans several months or even longer, gathering crucial data across diverse operational conditions. Factors such as sample size, the specific testing protocols involved, and the need for third-party verification can also influence the total timeframe for completion. Effective planning and clear communication with testing facilities can help provide realistic timelines based on individual requirements.

WHAT ARE THE POTENTIAL RISKS OF SKIPPING BATTERY TESTING?

Neglecting the testing phase can expose stakeholders to significant risks, primarily the potential for battery failure or unsafe operational conditions. Without diligent assessments, performance inconsistencies could manifest, endangering both personnel and equipment. Furthermore, unreliable batteries can trigger expensive downtimes, severely impacting productivity. In extreme cases, untreated safety non-compliance may culminate in catastrophic failures, leading to legal ramifications and financial losses. Thus, committing to thorough testing safeguards investments and fosters confidence in reliability and performance through the lifecycle of the battery.

Engaging in testing for energy storage batteries is an essential investment that ensures they meet specified standards and perform reliably in real-world scenarios. The total expenditure associated with this process is influenced by a multitude of factors, including battery technology, scale, compliance requirements, and the choice of testing facility. While costs may initially seem daunting, the assurance of reliability, safety, and longevity provided by comprehensive evaluation justifies the financial commitment involved. Detailed understanding of different testing procedures and their inherent complexities further clarifies budget allocations for effective project management. By prioritizing extensive testing, individuals and organizations alike can mitigate risks associated with battery failure while bolstering their operational capabilities. In an era where energy reliability is paramount, investing in proper battery testing not only safeguards assets but also contributes to the broader objective of efficient energy utilization across diverse domains.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-much-does-energy-storage-battery-testing-cost/