How many volts is the DC load end of the MPPT solar controller? The DC load end of an MPPT solar controller typically operates at voltages ranging from 12 volts to 48 volts, primarily depending upon the configuration of the solar power system in use. 1. The most common operational voltage for small-scale systems is 12V or 24V, while larger installations often utilize higher voltages such as 48V for efficiency. 2. The specific voltage setting is crucial for optimizing energy consumption and determining the compatibility with connected devices. 3. Understanding the operational range is important for selecting the appropriate solar equipment and ensuring safe and efficient power distribution. The voltage at the DC load end has significant implications for performance and should be selected based on the energy requirements of the end appliances.

1. OPERATIONAL VOLTAGE RANGES OF MPPT SOLAR CONTROLLERS

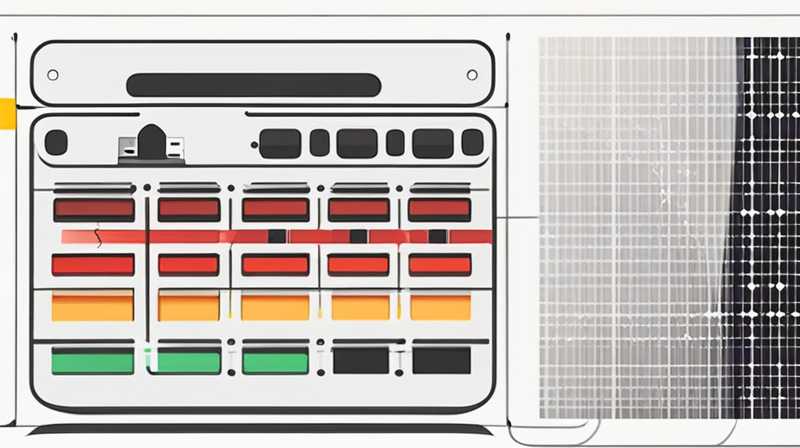

The operational voltage ranges of MPPT (Maximum Power Point Tracking) solar controllers are essential for maximizing the efficiency of a solar power system. These controllers are designed to optimize the amount of energy harvested from solar panels by dynamically adjusting the electrical operating point of the modules. The DC load end voltage is a fundamental aspect that dictates how energy is distributed to various loads, which can range from household appliances to battery charging systems.

Typically, these controllers come configured for a range of operational voltages, including 12V, 24V, 36V, and 48V. The choice of voltage depends significantly upon the solar panel system’s design and the specific application for which it is intended. For instance, small residential setups often utilize 12V systems while commercial applications may adopt 48V configurations to improve energy transfer efficiency and reduce power losses.

Advancements in technology have allowed for a wider variety of configurations, which have thus become standard practice in the solar industry. This flexibility is particularly beneficial for large-scale solar installations, as higher voltages can translate to greater system efficiencies, leading to lower operational costs and improved return on investments. It is crucial to acknowledge that operating at different DC voltages has implications on the overall compatibility and integration of the components used within the system.

2. FACTORS INFLUENCING DC LOAD VOLTAGE

Several factors influence the selected voltage for the DC load end of an MPPT solar controller. The primary factor is the type of battery bank utilized within the system. Batteries are typically rated for specific voltages, and selecting a compatible solar controller is essential to ensure that energy can be safely and efficiently stored. Most batteries in residential systems are either 12V or 24V, necessitating MPPT controllers that can accommodate such voltages.

Another aspect to consider is the specific electrical load connected to the solar system. Different devices have unique voltage requirements, necessitating careful consideration when configuring electrical systems. For example, standard appliances may operate well on a 12V or 24V setup, while more energy-intensive equipment may require 48V or higher. Therefore, a savvy approach to voltage selection involves analyzing all loads and the energy output requirements.

Additionally, system efficiency plays a pivotal role in determining DC load voltage. Higher operating voltages can enhance the system’s efficiency by reducing current flow, which in turn minimizes resistive losses that occur during transmission. This efficiency is particularly vital when considering long cable runs. Reduced current also extends the lifespan of system components, primarily cables and connectors, which need to withstand lower thermal stresses.

3. IMPLICATIONS OF INCORRECT VOLTAGE SETTINGS

The ramifications of improper voltage settings at the DC load end of an MPPT solar controller can be significant. One immediate consequence is the potential damage to system components. If the voltage is too low, it may cause devices connected to the system to not operate properly, leading to performance inefficiencies. Conversely, operating above the rated voltage can result in component failure, as they may not be designed to handle excessive electrical pressure, leading to costly repairs and downtime.

Further, voltage mismatches can hinder the ability to store energy effectively within battery systems. When batteries are charged at incorrect voltages, not only can they suffer from overcharging, but they can also fail to charge at all in the cases of under-voltage. Both scenarios can severely limit the efficiency and reliability of the entire solar power system.

Moreover, the lack of standardization in voltage ratings can complicate system design. Different manufacturers may use diverse voltage standards, leading to confusion when integrating various components. This inconsistency makes it critical for system designers to understand the voltage requirements and ensure all parts are compatible. Using mismatched voltages can lead to operational errors and lower overall solar system performance.

4. BEST PRACTICES FOR CONFIGURING MPPT VOLTAGE SETTINGS

To achieve optimal performance from an MPPT solar controller, several best practices should be observed regarding the DC load voltage end configuration. Utilizing a reliable voltage measurement tool is crucial for ensuring precision in voltage settings. Advanced multimeters or specific solar performance testing equipment can provide accurate readings and assist in diagnosing any discrepancies in expected performance.

Another valuable practice involves consulting manufacturer specifications and guidelines. Each MPPT solar controller will come with detailed parameters for its voltage settings. Familiarity with these specifications will aid in the installation process, as users can tailor their systems to fit within the recommended voltage ranges.

Furthermore, regular system maintenance and monitoring should not be overlooked. Monitoring voltage levels can help preempt potential issues, such as those resulting from component deterioration over time. Scheduling routine inspections can identify early signs of trouble, such as voltage drops or surges, allowing for prompt responses that can mitigate costly repairs or system failures.

5. COMPARATIVE ANALYSIS OF SOLAR CONTROLLERS

When evaluating the performance of various solar controllers, it is essential to conduct a comparative analysis of the different types available. MPPT solar controllers are often seen as superior to PWM (Pulse Width Modulation) controllers due to their ability to maximize power output. MPPT technology tracks the maximum power point of solar panels and adjusts accordingly, providing a constant load voltage that can adapt to fluctuations in panel performance.

In contrast, PWM controllers function by regulating voltage levels but often do not optimize energy harnessing as effectively as MPPT systems. For larger installations or those with high energy demands, the choice of an MPPT controller often provides a higher energy return on investment due to enhanced efficiency at varying voltages.

When selecting between different models, it is critical to analyze specifications, efficiency ratings, and compatibility with your specific load profiles. This analysis should consider not only the nominal voltage ratings but also current capacity, temperature coefficients, and build quality. By doing so, system planners can ensure they select controllers that will proficiently meet their operational needs and maximize solar energy utilization.

6. THE FUTURE OF DC LOAD END VOLTAGE IN SOLAR APPLICATIONS

As solar technology continues to evolve, the landscape of DC load end voltage configurations is also changing. Innovations in battery storage technology are leading to the development of smart energy systems that can dynamically adjust their operational voltages based on real-time energy demand. These advancements are making it increasingly feasible to integrate renewable energy systems into smart grids, where energy can be efficiently managed to respond to varying consumption patterns.

Additionally, as the market for electric vehicles (EVs) expands, the need for standardized voltage levels increases. This evolution demands that solar controllers adapt accordingly, ensuring compatibility with increasingly sophisticated battery management systems. Manufacturers will need to respond to these trends by innovating technologies that allow for seamless interaction between solar energy and EV charging requirements.

Moreover, the emphasis on sustainability and energy efficiency is pushing manufacturers to focus on creating controllers that serve a dual purpose of charging batteries while also providing real-time load management. Future solar systems might emphasize not only energy generation but also load balancing to maximize usage of renewable energy resources. This forward-thinking approach could greatly influence how DC load voltages are set and regulated in solar applications moving forward.

FAQs

WHAT IS THE STANDARD DC VOLTAGE RATING FOR MPPT SOLAR CONTROLLERS?

Standard DC voltage ratings for MPPT solar controllers usually range between 12 volts and 48 volts. The chosen voltage typically aligns with the configuration of the solar energy system in place. Smaller residential systems often operate at 12V or 24V, making them suitable for everyday household applications. Meanwhile, larger solar installations lean toward 48V configurations because they enhance efficiency and reduce losses in energy transfer. Proper alignment of voltage ratings with system design is crucial for maximizing the overall efficacy of the solar power setup.

HOW DOES THE VOLTAGE AT THE DC LOAD END AFFECT SYSTEM PERFORMANCE?

The voltage at the DC load end significantly impacts performance. An adequately matched voltage setting ensures that connected devices operate as intended. If the voltage is too low, appliances may not function correctly, leading to performance inefficiencies. Conversely, excessively high voltage can damage the components or connected devices, resulting in expensive repairs. High voltage configurations can also improve system efficiency by minimizing current flow, thus reducing resistive losses. Therefore, careful consideration at the DC load end is paramount for achieving optimal energy usage and ensuring system longevity.

CAN I CHANGE THE DC LOAD VOLTAGE SETTING OF MY MPPT CONTROLLER?

Changing the DC load voltage setting of your MPPT solar controller is possible but must be done with caution. Most controllers come with specific voltage settings designed to correspond with the solar system’s requirements. While many modern controllers allow for user adjustment, it is paramount to adhere to manufacturer guidelines to avoid damaging either the solar components or connected devices. If adjustments are made, it is advisable to continually monitor the system to assess the impact on performance. Additionally, it may require a deeper understanding of the entire system architecture to make meaningful adjustments without compromising efficiency or safety.

WHAT ARE THE ADVANTAGES OF USING MPPT CONTROLLERS OVER PWM CONTROLLERS?

The advantages of employing MPPT over PWM controllers lie primarily in their efficiency and flexibility. MPPT (Maximum Power Point Tracking) technology continually analyzes solar panel outputs, optimizing energy harvesting throughout variable conditions, thus maximizing power output. In contrast, PWM (Pulse Width Modulation) controllers are limited to regulating voltage without dynamically tracking power output, resulting in lesser performance under certain conditions. For users seeking to improve system efficiency, especially in larger installations or those demanding high outputs, MPPT controllers offer better returns on investments through optimized energy use.

The exploration of DC load voltage configurations in MPPT solar controllers highlights critical considerations for efficiency, compatibility, and operational performance. Understanding the selection criteria for voltage settings, along with the factors that influence their performance, can ensure a well-functioning solar setup. Properly implemented voltage adjustments enable maximized electricity generation while accommodating varying energy loads. This is essential for both residential users and commercial installations. To maintain peak performance, continual monitoring and periodic adjustments may be required. As solar technologies advance, the scope for integrating systems across different applications will expand, further enhancing energy utilization. Thus, insights into voltage configuration will remain a vital area for discussion and development in the coming years. Engaging with these innovations is crucial for anyone invested in sustainable energy solutions.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-many-volts-is-the-dc-load-end-of-the-mppt-solar-controller/