1. Industrial solar panels typically operate at voltages ranging from 12 volts to 1,500 volts, depending on the application and configuration. 2. The standard voltage for most commercial installations is usually around 600 volts, which facilitates efficient energy conversion and transfer to the grid. 3. A significant factor influencing the voltage is the panel’s design and the inverter technology employed, ensuring maximum power output and compatibility with various energy systems. 4. Moreover, higher voltage systems, such as those reaching 1,500 volts, are advantageous for large-scale installations, minimizing losses during transmission, thus optimizing overall efficiency.

1. UNDERSTANDING SOLAR PANEL VOLTAGE

In the realm of photovoltaics, understanding the intricacies of solar panel voltage is crucial for optimizing energy production. Solar panels, fundamental components of solar energy systems, convert sunlight into electricity. However, not all solar panels are created equal. Voltages can vary widely, influenced by design, application, and integration into larger systems. Industrial solar panels, often deployed in commercial settings, tend to operate at higher voltages compared to residential models, allowing for improved efficiency and energy management.

The importance of voltage in solar panels cannot be understated. Higher voltage systems can facilitate long-distance transmission of electricity with reduced losses, thus supporting the sustainable operation of large-scale solar facilities. Voltage is inherently linked to the inverter technology utilized, as inverters play a key role in converting direct current (DC) produced by solar panels into alternating current (AC) suitable for use in the energy grid. Moreover, understanding the relationship between the number of panels connected (series or parallel configurations) and voltage can help in designing efficient solar array systems.

2. VOLTAGE CONFIGURATIONS IN INDUSTRIAL SOLAR PANELS

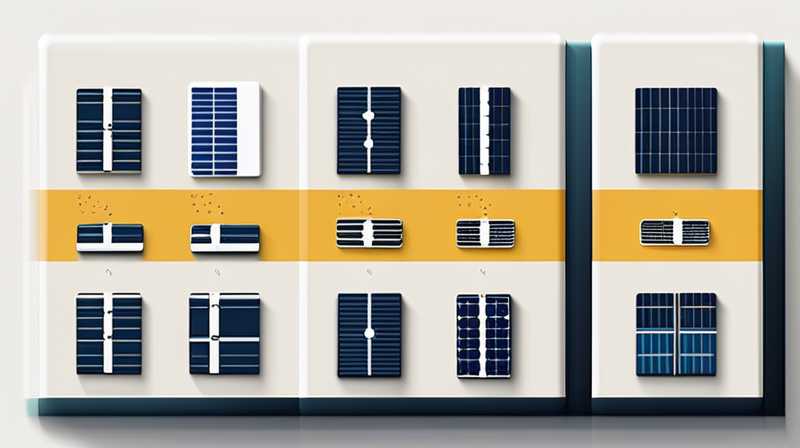

Industrial solar panels can be categorized based on their voltage configurations. Common configurations include low voltage (around 12 to 48 volts), medium voltage (600 volts), and high voltage (up to 1,500 volts) systems. Each configuration serves specific purposes and applications, with varying degrees of efficiency and performance.

Low voltage systems are typically utilized in smaller installations or off-grid applications, where energy consumption is lower, and simplicity in design and installation is prioritized. Conversely, medium voltage systems are more prevalent in commercial settings, providing a balanced option that supports greater energy demands without compromising safety. High voltage systems, often associated with large utility-scale solar plants, achieve enhanced efficiency by minimizing losses during transmission. These systems require careful engineering to ensure safety and reliability as well as compliance with electrical standards.

The configuration of industrial solar panels also impacts the choice of inverters, which must match the voltage output of the panels to ensure optimal performance. String inverters, typically used in medium voltage settings, convert the DC output from multiple panels in series. On the other hand, central inverters, ideal for high voltage applications, handle large arrays of panels, promoting efficient energy conversion on a larger scale.

3. IMPACT OF VOLTAGE ON EFFICIENCY AND COST

The voltage level of industrial solar panels plays a significant role in determining the efficiency and overall cost of solar energy systems. Higher voltage systems generally lead to increased energy efficiency, as the lower current levels associated with higher voltages reduce resistive losses during transmission. This is particularly relevant in long-distance transmission scenarios, where energy can be lost due to the resistance of wires and other components.

In terms of cost, while higher voltage systems might entail a greater initial investment for components and safety measures, the overall savings in efficiency can result in lower operational costs. This is especially pertinent for utility-scale solar projects, where minimizing operational and maintenance expenses directly influences profitability. Additionally, larger installations can take advantage of economies of scale, leading to further cost reductions in manufacturing and installation processes.

Moreover, the choice of technology and materials used in constructing higher voltage panels and their corresponding inverter systems affects the overall cost and lifespan of solar installations. For instance, premium materials that enhance voltage handling capabilities may incur a higher upfront cost but can ultimately lead to greater long-term savings and efficiency.

4. SAFETY CONSIDERATIONS WITH HIGH VOLTAGE SYSTEMS

While the advantages of higher voltage systems in industrial solar panels are evident, they also introduce unique safety considerations. Higher voltages pose more significant risks, necessitating stricter safety protocols and guidelines during installation and maintenance. Proper training for personnel involved in the installation and management of these systems is essential to mitigate risks associated with electric shock or arcs.

Safety measures include adequate insulation, appropriate circuit protection devices, and robust monitoring systems to detect faults or anomalies in real time. The correct implementation of National Electrical Code (NEC) guidelines and local regulations is critical. Additionally, emergency procedures must be established and regularly reviewed to ensure that all personnel are familiar with best practices in case of a fault or emergency.

Furthermore, the design of the solar array must allow for safe access for maintenance without compromising the integrity of the voltage system. Equipment and tools used during service must be rated for the voltage levels of the system to prevent accidents and ensure compliance with safety regulations. Ultimately, pursuing safety alongside higher efficiency becomes the backbone of any successful industrial solar installation.

5. FUTURE TRENDS IN SOLAR PANEL TECHNOLOGY

The landscape of solar panel technology is ever-evolving, marked by innovative approaches and advancements in efficiency, design, and sustainability. Emerging trends indicate potential shifts in the functioning and application of industrial solar panels, with researchers and manufacturers striving to enhance both performance and usability.

One prominent trend is the development of bifacial solar panels, which capture sunlight on both sides, maximizing energy production and increasing the overall output from an installation. Additionally, advancements in perovskite solar cells offer the potential for higher efficiency at lower costs, contributing to the growing trend of integrating advanced materials into manufacturing processes.

Another critical trend includes the incorporation of smart technology and enhanced monitoring solutions. With the advent of the Internet of Things (IoT) in renewable energy, panels equipped with intelligent sensors can provide real-time data on performance, enabling more informed decision-making for system management and maintenance. This can enhance the operational efficiency and longevity of industrial solar installations, ultimately leading to greater grid efficacy.

Finally, sustainability within manufacturing practices is becoming a significant focal point. Increased demand for eco-friendly materials and processes in solar panel production contributes to a more sustainable energy landscape. Evaluating the lifecycle impacts of solar panels encourages manufacturers to adopt practices that minimize waste and enhance recyclability, aligning with global sustainability goals.

FREQUENTLY ASKED QUESTIONS

WHAT IS THE TYPICAL VOLTAGE RANGE FOR INDUSTRIAL SOLAR PANELS?

When discussing the typical voltage range for industrial solar panels, it is essential to consider the specific application, type, and design of the solar energy system involved. Most industrial solar panels operate between 12 to 1,500 volts, with 600 volts being the standard for many commercial applications. This range facilitates efficient energy transfer while ensuring compatibility with various inverter technologies.

Higher voltage systems, particularly those reaching 1,500 volts, allow for better efficiency and reduced losses during the transmission of electricity. Such systems are often found in large-scale utility installations, where energy needs are substantial, and efficiency is paramount. Additionally, the choice between using low, medium, or high voltage depends on factors such as project scale, layout, and regulatory requirements. Understanding these dynamics aids in making informed decisions when selecting solar panel configurations tailored to specific needs.

HOW DOES VOLTAGE INFLUENCE SOLAR PANEL EFFICIENCY?

Voltage plays a significant role in the overall efficiency of solar panels and the systems in which they are integrated. Higher voltage configurations typically reduce current flow, which minimizes resistive losses during the transmission of electricity. This is especially crucial in large-scale solar installations, where long-distance energy transfer is common. By operating at elevated voltages, industrial solar systems can efficiently deliver power to the grid while ensuring optimal energy production.

Moreover, the selection of inverter technology influences the relationship between voltage and efficiency. Different types of inverters, such as string or central inverters, perform optimally with specific voltage ranges, contributing to overall system efficiency. Higher voltages allow for fewer losses, leading to higher yields over time. Thus, understanding voltage dynamics is central to maximizing the performance of solar energy installations while ensuring cost-effectiveness and reliability.

WHAT SAFETY MEASURES SHOULD BE CONSIDERED FOR HIGH VOLTAGE SOLAR SYSTEMS?

Implementing high voltage solar systems requires stringent adherence to safety measures to mitigate risks associated with electrical hazards. Effective safety protocols involve proper training, installation practices, and continuous monitoring. Personnel engaged in the installation and maintenance of high voltage systems must be well-versed in safety guidelines, including the use of certified equipment and tools rated for the specific voltage levels.

Furthermore, insulation and protective equipment are essential components of high voltage system safety. Robust circuit protection devices, such as fuses and circuit breakers, serve as critical safeguards when encountering overcurrent or faults. The design of solar arrays must also facilitate safe access for routine maintenance, reducing exposure to potential risks. Lastly, emergency protocols must be established, ensuring all team members are prepared to respond effectively to any incidents.

In summary, high voltage systems can provide significant advantages in terms of efficiency and operational cost savings, but they necessitate a strong focus on safety to protect personnel and infrastructure. Each layer of safety intentions contributes to the sustainable development and deployment of solar energy solutions.

FINAL THOUGHTS ON INDUSTRIAL SOLAR PANEL VOLTAGE

The realm of industrial solar panels is marked by complexity, with voltage being a pivotal aspect that directly influences efficiency, cost-effectiveness, and system integrity. Understanding the operational voltage ranges, including low, medium, and high voltage systems, allows for informed decision-making and optimized energy production. The choice of configuration not only impacts the performance of individual panels but also plays a crucial role in ensuring that the entire solar energy system operates harmoniously.

As technology continues to evolve, trends such as bifacial solar panels and smart monitoring systems will further shape the landscape of industrial solar energy. These innovations enhance overall efficiency while accommodating growing energy demands and sustainability goals. Moreover, high voltage systems pave the way for substantial efficiency gains, particularly as the need for expansive energy transmission solutions becomes more pronounced in an increasingly electrified world.

Safety remains a paramount concern as the adoption of higher voltage systems expands. Implementing robust safety measures and protocols is crucial to protecting personnel and equipment while promoting reliable energy generation. Therefore, a comprehensive understanding of both the benefits and challenges associated with industrial solar panel voltages is essential for stakeholders involved in the renewable energy sector.

Ultimately, evaluating the implications of voltages in industrial solar panels reveals a nuanced landscape where efficiency, safety, and technological advancements converge. Continuous innovation and adherence to best practices will define the future trajectories of solar energy, ensuring that it remains a pivotal component of the global energy transition toward sustainability.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-many-volts-is-an-industrial-solar-panel/