1. There are typically between 60 to 72 silicon wafers in a standard solar panel, depending on its design and efficiency. 2. Each wafer is a thin slice of silicon that converts sunlight into electricity through the photovoltaic effect, which is the fundamental principle behind solar energy generation. 3. The number of wafers can influence the overall performance, efficiency, and even the cost of the solar panel, making it a significant factor for consumers and manufacturers alike. 4. Higher wafer counts can lead to increased energy production, while improved manufacturing technologies have also enhanced efficiency metrics, thereby reducing the number of wafers needed for optimal energy output.

THE SIGNIFICANCE OF SILICON WAFERS IN SOLAR TECHNOLOGY

The solar energy sector has witnessed remarkable advancements over the years, making it an attractive alternative to fossil fuels. At the heart of solar panels lies the silicon wafer, a crucial component that dictates not only the efficiency but also the economic feasibility of solar energy systems. Silicon wafers serve as the foundational building blocks for photovoltaic cells, capturing sunlight and converting it into usable electricity. Understanding the dynamics of silicon wafers can shed light on various aspects, such as their production process, the technology involved, and the advantages they offer.

Silicon wafers are thin slices of silicon that have undergone a series of intricate manufacturing processes. Each wafer acts as a medium to facilitate the solar energy conversion process. The manufacturing of these wafers involves doping, cutting, and polishing silicon ingots to obtain high-purity wafers that have the required electrical properties. Consequently, these highly purified wafers enhance the performance of solar cells, elevating the efficiency of the solar panels.

1. TYPES OF SILICON WAFERS USED IN SOLAR PANELS

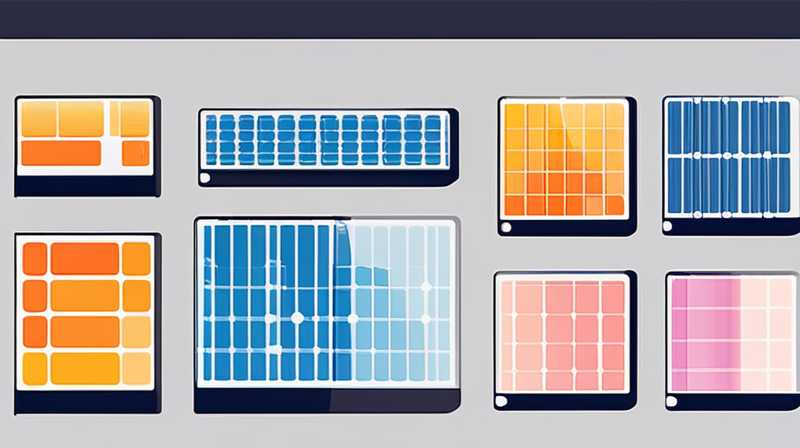

When exploring the realm of silicon wafers, it is essential to distinguish between various types. Monocrystalline and polycrystalline wafers are the two primary categories that dominate the solar market. Each has distinct attributes that influence their selection in solar panel production.

Monocrystalline silicon wafers are crafted from single, continuous crystals of silicon. This uniformity leads to higher efficiency rates, usually ranging between 15% to 22%. Their sleek design and dark color make them visually appealing, which is a significant consideration for residential installations. Moreover, the manufacturing process yields fewer waste materials, making it an eco-friendly option. One of the significant advantages of monocrystalline wafers is their performance in low-light conditions, making them ideal for installations in areas with less sunlight exposure. However, the high production cost can deter some consumers from opting for monocrystalline panels.

Contrastingly, polycrystalline silicon wafers are composed of multiple silicon crystals, which give them a bluish hue and a more rugged appearance. They are generally more affordable compared to their monocrystalline counterparts, making them an attractive option for budget-conscious buyers. Yet, this affordability comes at a cost; polycrystalline panels typically exhibit lower efficiency levels, usually falling between 13% to 16%. While still effective, polycrystalline wafers require more surface area to produce the same energy output as monocrystalline ones, making them less suitable for small rooftops. Another consideration of polycrystalline technology is its performance under high-temperature conditions, where it can often achieve remarkable performance levels.

2. THE ROLE OF WAFER COUNT IN SOLAR PANEL DESIGN

In the construction of solar panels, the number of silicon wafers plays a pivotal role in determining the overall design and functionality of the panel. A higher wafer count generally correlates with increased energy production potential, as more wafers allow for greater surface area to capture sunlight. However, the correlation is not linear; various factors influence the design choices made by manufacturers.

The traditional solar panel configuration generally involves arrays of 60 or 72 wafers, which balance efficiency, cost, and size considerations. Panels with 60 wafers are often utilized in residential applications where space can be a constraint, while those with 72 wafers might be employed in commercial or utility-scale installations due to their higher power output. The choice of wafer count impacts not only the output but also the dimensions of the panels themselves. Design engineers often need to strike a delicate balance between maximizing efficiency while ensuring manufacturability and affordability.

Additionally, the ongoing trend towards higher efficiency levels in solar technology has prompted manufacturers to innovate their designs by either reducing the size of the wafers or increasing their interconnectivity within the panel. Technologies such as half-cut cells and bifacial solar panels have emerged in response to these needs. Half-cut cells are derived from cutting standard wafers into two halves, allowing for a higher density of cells per panel. This design utilizes additional interconnections to enhance voltage, thereby reducing resistive losses and improving overall panel efficiency.

3. MANUFACTURING PROCESSES INVOLVED IN SILICON WAFER PRODUCTION

The transformation of raw silicon into usable solar wafers is a meticulous process imbued with advanced technological interventions. Understanding these stages provides insights into what contributes to the final quality of solar panels. The entire manufacturing process involves several critical steps: crystallization, slicing, etching, and doping.

Initially, silicon is purified from silica that is often mined from quartz. This purified silicon is then melted and subsequently formed into large cylindrical ingots. The crystallization method significantly influences the quality of the wafers produced. Monocrystalline ingots are produced through the Czochralski method, where a seed crystal is dipped into molten silicon and slowly withdrawn, allowing for the formation of a single crystal. In contrast, polycrystalline ingots are created by melting multiple silicon crystals together, leading to a more complicated crystal structure.

Following crystallization, the ingots undergo slicing into thin wafers using wire saws. This slicing process is crucial as it determines the thickness of each wafer, which can range from 180 to 220 micrometers. Thinner wafers generally contribute to lower material costs but may also lead to increased susceptibility to damage. Once sliced, the wafers proceed through an etching process that removes imperfections from the surface, ensuring that the cells can efficiently capture sunlight. Finally, the doping process incorporates elements like phosphorous or boron into the silicon to create p-type and n-type semiconductors. This step is vital for establishing an electric field that facilitates the flow of electricity when exposed to sunlight.

4. INFLUENCE OF TECHNOLOGICAL ADVANCEMENTS ON SILICON WAFERS

The landscape of solar technology is dynamic and continually evolving, mainly driven by innovations that enhance the efficiency and durability of silicon wafers. Recent findings have introduced concepts like Passivated Emitter and Rear Cell (PERC) technology and bifacial solar panels, which have significantly altered the performance benchmarks for solar installations.

PERC technology optimizes the back surface of the solar cells, adding a layer of passivation that reflects photons back into the silicon, allowing them to be reabsorbed. This leads to better conversion rates of sunlight into electricity. Technologically enhanced wafers can potentially increase efficiency levels by an additional 5% to 10%, thereby making solar energy generation more economically viable.

Bifacial solar panels incorporate a dual-sided design, allowing sunlight to be captured on both the front and back surfaces. This innovation can lead to performance gains in reflective environments, such as snowy or sandy terrains. These advancements are paving the way for increasingly efficient solar farms that utilize space and resources better, often leading to reduced energy costs over time.

Moreover, the development of materials such as heterojunction technology is set to offer unparalleled efficiency levels with reduced degradation rates. Advancing toward the integration of advanced materials will also likely lower manufacturing and installation costs, making solar energy even more appealing to a broader market.

FREQUENTLY ASKED QUESTIONS

HOW DOES THE NUMBER OF SILICON WAFERS AFFECT SOLAR PANEL EFFICIENCY?

The number of silicon wafers in a solar panel directly influences its efficiency and overall power output. Solar panels typically contain 60 to 72 wafers, with each wafer contributing to the surface area that captures sunlight. Increasing the number of wafers leads to a larger area for sunlight absorption, thereby boosting the potential energy output of the panel. However, higher wafer counts may also lead to increased production costs and material usage. Therefore, while the number of wafers affects efficiency, manufacturers must balance this with material costs and the physical dimensions of the solar panels themselves. In some cases, technological advancements and design innovations allow for panels to achieve high efficiency without an increased wafer count, thereby redefining the efficiency norms in solar technology.

WHAT ARE THE BENEFITS OF USING MONOCRYSTALLINE OVER POLYCRYSTALLINE SILICON WAFERS?

When it comes to solar panel designs, monocrystalline silicon wafers offer several advantages compared to polycrystalline options. Monocrystalline panels generally achieve higher energy conversion efficiencies, often between 15% to 22%, as they are made from single crystals that allow electrons to flow more freely. Consequently, they tend to perform better in low-light conditions and require less space for the same power output, making them suitable for applications where roof space is limited.

In contrast, polycrystalline panels tend to be more affordable and still effective, typically offering efficiencies ranging from 13% to 16%. However, the trade-off involves a larger panel size to generate equivalent power. Furthermore, monocrystalline panels have a longer lifespan and are generally covered by extended warranties, lending them an edge when considering long-term solar investments. Ultimately, the choice between the two types depends on budget considerations, space availability, and efficiency needs.

HOW DOES TECHNOLOGY INFLUENCE THE COST OF SOLAR PANELS?

Technological advancements play a crucial role in determining the cost structure of solar panels, including the silicon wafers utilized in their production. Modern manufacturing techniques and innovations such as PERC and bifacial solar technologies have contributed to enhanced efficiency rates and performance levels. Interestingly, these innovations may initially lead to higher costs due to research and development investments. However, over time, as these technologies gain widespread acceptance, economies of scale come into play, often leading to reduced manufacturing costs.

Additionally, advancements in materials can lead to lower degradation rates and extended lifespans for solar panels, thereby improving return on investment for consumers. As is evident, the interplay between technology and costs is multifaceted and involves consideration of both initial investment and long-term efficiency gains. Consequently, as technologies evolve, the overall affordability and effectiveness of solar energy systems continue to improve.

In the arena of solar energy production, silicon wafers play a pivotal role. Understanding their significance, varieties, and how they integrate into solar panel design underscores their vital importance in determining solar panel efficiency and overall energy generation. As technological advancements continue to influence engineering designs and manufacturing processes, the performance metrics associated with these wafers evolve, fostering an environment conducive to growth and innovation in renewable energy. The ongoing transitions in the solar sector reveal the complexities and dynamic nature of solar technology, where strategic product designs, material sciences, and innovative methodologies converge to attain higher efficiencies and greater adoption of renewable energy. Acknowledging these variables emboldens stakeholders—from manufacturers to consumers—to navigate the evolving landscape of solar energy effectively. Ultimately, it serves as a reminder of the essential nature of silicon wafers in shaping our sustainable energy future.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-many-silicon-wafers-are-there-in-a-solar-panel/