In the realm of solar heating, the quantity of pipes necessitated is contingent on various factors influencing the system’s efficiency and effectiveness. 1. The size of the solar collector area is paramount, as a larger area requires a more intricate network of piping to transport heated fluid. 2. The design of the heating system is crucial, with different layouts leading to varying piping needs. 3. The specific climate conditions play a significant role, while 4. The type of fluid circulating through the pipes influences design choices, as certain fluids may require specialized infrastructure.

Among these factors, the size of the solar collector area stands out in importance. A greater surface area allows for more solar energy absorption, but this also necessitates an expanded piping system to effectively channel heat from the collector to the storage tank or directly into the heating distribution system. In some instances, homes or buildings with larger roofs might opt for additional collectors, resulting in an increased number of pipes to connect the components seamlessly.

1. THE SIGNIFICANCE OF PIPE QUANTITY IN SOLAR HEATING

Understanding the implications of pipe quantity is pivotal for achieving desired performance outcomes in solar heating systems. The layout and design of the system are interdependent, and a defined relationship exists between the overall energy output and the number of pipes utilized in the configuration. When the pipe network is appropriately scaled to the solar configuration, enhanced efficiency will be achieved.

The diameter of pipes employed also impacts flow rates. Smaller pipes may lead to increased frictional losses, restricting fluid movement and diminishing overall efficiency. Conversely, larger pipes facilitate higher flow rates but can prove to be less economical in terms of material usage and installation costs. Proper sizing is critical in achieving an optimal balance where both the collector area and the pipe layout synergize to deliver efficient energy transfer.

1.1. INTERACTIONS BETWEEN COLLECTOR AREA AND PIPE DIMENSION

The selection of pipe diameter should be considerate of the collector size. In systems with extensive solar collectors, the necessity for larger pipes becomes evident, as they can accommodate significant volume increases in the fluid as it moves from collector to storage. Notably, this design approach can mitigate the risks of heat loss. Proper insulation can enhance performance, yet it must be balanced by appropriate sizing to ensure the fluid retains optimal temperature gradients during its transit.

Heat loss mechanisms must also be explored as they significantly affect a solar heating system’s effectiveness. Effective insulation around the pipes can reduce losses, yet if the diameter is too small, the increased velocity of fluid will precipitate turbulence, yielding atmospheric interactions that further complicate efficiency. Thus, understanding the frictional losses occurring within pipes remains critical.

2. SYSTEM CONFIGURATION AND PIPE REQUIREMENTS

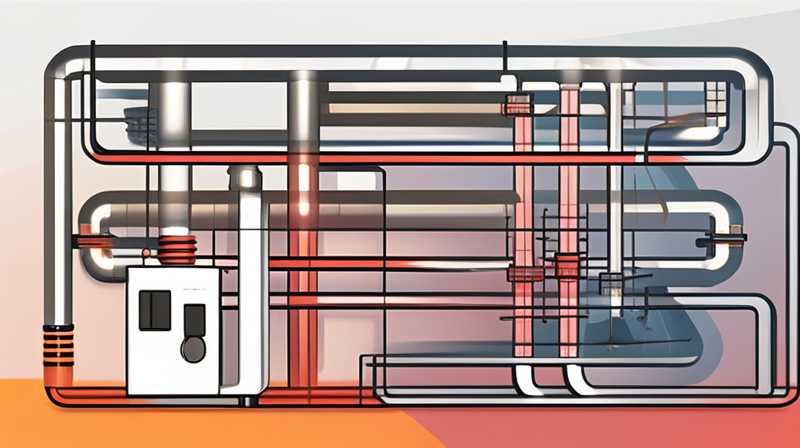

Different designs for solar heating systems necessitate varied approaches to piping. The distinctions between closed-loop systems and open-loop systems influence piping needs. Systems requiring pump-driven circulation often necessitate additional infrastructure to ensure fluid flows effectively and efficiently.

In a closed-loop system, a dedicated piping orientation moves heat-transfer fluid (often an antifreeze solution) between the collectors and the storage tank. This configuration should consider optimal pump sizing and pipe insulation to curtail energy losses. Additionally, attention must be given to the total distance between the fluid’s sources and destinations. Increased lengths can lead to losses that dilute system performance, leading to increased operational costs, and may even necessitate a greater number of pipes to lighten load on the pumps for effective circulation.

2.1. OPEN-LOOP SYSTEMS AND THEIR CONFIGURATION CHALLENGES

Contrastingly, open-loop systems utilize potable water as the circulating fluid, making them reliant on local climate qualities. While this configuration can simplify the overall setup, it also comes with its own set of dilemmas, particularly concerning freezing temperatures. Particularly in colder climates, the potential for freezing in pipes necessitates the installation of additional lines for ensuring flow perspectives regardless of temperature variations seasonally.

Pipe selection is also dictated by distance considerations. In systems where the collector resides distanced from the storage or distribution location, ample length and your method of running pipes (such as elevation or horizontal runs) need thorough planning. Furthermore, if large lengths are unavoidable, considering a schematic design replete with junctions and additional fittings is essential. Every junction or curve exposes fluid to resistive forces, potentially lowering efficiency.

3. CLIMATE CONSIDERATIONS IMPACTING PIPE QUANTITY

The elements encompassing the local climate must distance considerations when determining pipe numbers and sizes in solar heating systems. The efficiency of energy transfer is often contingent upon ambient conditions, significantly influencing fluid viscosity and thermal properties.

Temperature fluctuations influence fluid behavior. In places with extreme lows, the system requires additional protocols to preclude freezing, which might imply increased pipe counts. Expanding or insulating existing pipes can provide augmentation to ensure fluid circulation remains uninterrupted, and sufficient numbers of lines can serve as a backup in systems beset with performance inefficiencies during those rigorous times.

3.1. ACCOUNTING FOR HEAT LOSSES DUE TO CLIMATE

Heat losses due to temperature disparities become a significant concern in colder regions. More pipes may be required to circulate heated fluid back to the storage tank within these climatic territories. In many cases, multiple small lines are preferred in lieu of a singular large pipe to enhance area surface coverage, subsequently reducing potential heat losses during transportation.

Simultaneously, in pandemic regions subject to excessive sun exposure, efficient material selection for piping becomes paramount. Utilization of materials tailored for high-temperature environments can enhance longevity while minimizing the number of replacements required as thermal fatigue may set in.

4. FLUID TYPE AND ITS INFLUENCE ON PIPE DESIGN

The choice of circulating fluids is fundamental when defining pumping scenarios and the required pipe systems. Antifreeze solutions, typically used in closed-loop systems, necessitate pipes with specific characteristics resistant to corrosion and wear over time.

When utilizing water, it is less corrosive but can present problems during periods of stagnation unless proactive measures are instated. The type of fluid impacts not only the installation process but also future maintenance routines that can warrant different numbers of pipes or alternative configurations to maintain system efficacy.

4.1. MONITORING AND MAINTENANCE OF PIPING COMPONENTS

Requirements for system vigilance and routine checks evolve from the type of fluid employed. In addition to common wear and tear, monitoring for potential leaks is vital, particularly with systems handling reactive solutions. Consequently, the complexity of a pipe system relies heavily on the selected liquids and their physical characteristics. As such, stringent standards in patience are required throughout the lifespan of any installed system based on those fluid choices.

In cases where particular environments dictate more extensive interactions with different fluid properties or behaviors, this must be accounted for during the planning phase. Overall, the ramifications of fluid choice cascade throughout the entire layout and design of solar heating systems, influencing efficiency holistically.

FAQs

HOW DOES PIPE LENGTH AFFECT A SOLAR HEATING SYSTEM?

The length of pipes utilized in a solar heating system exerts significant influence over performance. As pipes extend, fluid must navigate increased frictional resistance, which can inadvertently diminish heat transfer efficiency. Moreover, longer runs increase the likelihood of thermal losses, as heat dissipates more readily in extended systems. Strategically insulating pipes and choosing appropriate diameters can help mitigate these losses; however, in the design phase, careful pre-planning is critical to maintain optimal flow and temperature retention throughout the system.

WHAT MATERIALS ARE USUALLY USED FOR SOLAR HEATING PIPES?

Common materials for solar heating pipes largely include copper, PEX, and PVC. Copper is lauded for its high thermal conductivity, though it can be cost-prohibitive. PEX, or cross-linked polyethylene, offers excellent resistance to thermal fluctuations and is more flexible, making it easier to handle during installations. PVC, on the other hand, is commonly indicated in low-temperature applications. Each of these materials carries distinct advantages, and their selection should align with specific system conditions and fluid types for optimal performance.

HOW OFTEN SHOULD SOLAR HEATING PIPES BE MAINTAINED?

Regular maintenance of solar heating pipes should occur at least once annually to prevent issues such as blockages or leaks. Furthermore, routine checks should involve inspections for wear-and-tear, confirming insulation integrity, and ensuring that fluid build-up does not compromise the efficiency of the system. By prioritizing these evaluations, users can mitigate larger problems while optimizing the operation and longevity of the solar heating system.

In reviewing the necessity of pipe systems in solar heating, multiple potential influences demand attentiveness. Various elements, from climate-induced temperature variances to the interaction with different fluids, all yield implications that resonate throughout the entirety of the project. The method in which these pipes work together orchestrates the ultimate functionality of the heating system, contributing to energy efficiency, environmental conservation, and potentially increased utility savings for homeowners and businesses embracing renewable energy solutions.

Determining the appropriate number of pipes requires a comprehensive assessment of these diverse considerations. A cohesive understanding of the foundational elements involved in each distinct installation and the correct configuration will ensure high efficiency and successful implementation. For this renewable resource technology to flourish, thoughtful planning around pipe size, layout, material choice, and fluid type is fundamental, culminating in a system that provides warmth and comfort for years to come. Thus, integrators and end-users must engage in ongoing evaluation and adjustments as the technology evolves, further refining their approach to harnessing the sun’s energy.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-many-pipes-are-needed-for-solar-heating/