To determine the necessary meters of pipes for the 6th floor of solar power installations, several factors must be taken into consideration, including 1. the layout of the building and solar system, 2. local regulations regarding pipe installation, 3. the type and size of solar system, and 4. climatic and environmental impacts that may affect piping needs. The total meters of pipes required will vary based on the above elements, making it critical to conduct a thorough assessment. One significant aspect in detail is the layout of the building and system design, which requires careful calculation to ensure efficiency and functionality.

1. UNDERSTANDING PIPE REQUIREMENTS

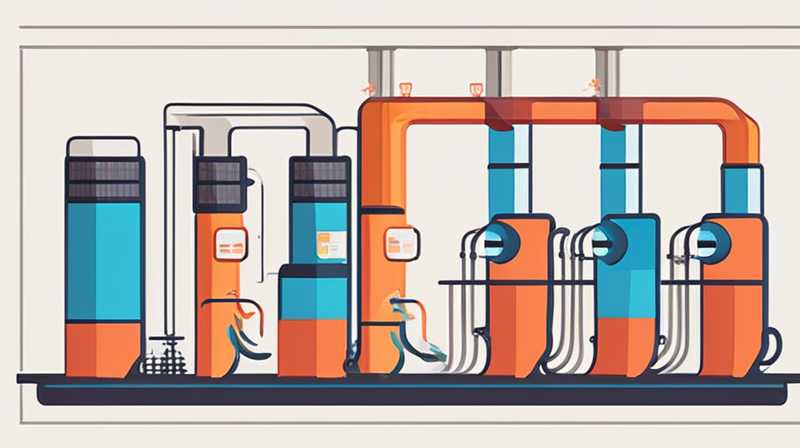

The complexity of solar power installations often necessitates a sophisticated understanding of piping systems. When assessing the layout of the building and the solar array’s positioning, careful planning can optimize energy delivery and minimize potential losses. For the 6th floor of a structure, horizontal and vertical piping routes play crucial roles.

Vertical runs from the roof-mounted solar panels to the inverter systems on the ground floor must be systematically calculated to reduce losses during energy transmission. Furthermore, the distribution of hot water or fluids to different parts of the building could influence the amount of piping required, depending on whether the solar system aims to provide heating or to power electrical systems.

Environmental conditions also dictate how pipes must be installed. Corrosive environments demand materials that can withstand specific conditions, ultimately increasing the necessary length of pipes due to extra protective measures. Hence, understanding both the internal layout and external environmental factors can lead to a more efficient piping plan.

2. DETERMINING PIPE LENGTH BASED ON SYSTEM TYPE

The type of solar system chosen—be it photovoltaic (PV) or solar thermal—will determine the kind and length of piping required. For solar thermal installations, the piping primarily serves to transport heated fluid from collectors to storage tanks or heating systems. Given this application, the material and insulation used in the pipes influence the size and type of piping utilized, adding further complexity to calculations.

Photovoltaic systems may require less piping than thermal systems, as they mainly need wiring for electrical connections. However, multiple setups might necessitate additional piping for efficient energy transportation back to inverters and storage systems. The relationship between the equipment and the piping network emphasizes the necessity of precise calculations on the types and sizes of pipes to ensure optimal performance.

Another factor to consider is the distance from the solar panels to the point of energy use or distribution. Long distances demand thicker pipes or increased numbers of them to mitigate pressure losses and ensure adequate performance. Accurate estimations regarding these parameters are imperative for determining the total length of piping installations.

3. REGULATORY CONSIDERATIONS

Local regulations significantly impact the choice and length of pipes needed for solar installations. Different regions have distinct building codes and permitting procedures that can influence the type of materials used, installation techniques, and overall design considerations. Compliance with these regulations is vital for the operational viability of solar power systems.

Moreover, some jurisdictions may mandate specific standards for pipeline insulation to preserve energy resources effectively. Noncompliance can lead not only to inefficiencies but also to potential legal entanglements. Understanding these regulations early in the planning process can streamline installations and avoid costly adjustments down the line. Consequently, every team member involved in the solar project must be fluent in local regulations governing such installations.

4. CLIMATIC AND ENVIRONMENTAL IMPACTS

The climatic conditions of the installation site determine the necessary features of the piping system. In regions experiencing extreme temperatures, the choice of pipe materials must accommodate thermal expansions and contractions. Insulation is essential to minimize heat loss in solar thermal systems, increasing the number of meters needed by ensuring protective layers are applied effectively.

Additionally, the environmental surroundings affect the pipelines’ longevity and efficacy. For example, chemical residues or high humidity levels necessitate specific pipe materials that can withstand degradation. Deterioration impacts flow efficiency and can lead to higher maintenance costs, thus further emphasizing the need for precise material selection and initial planning.

5. COST IMPLICATIONS

Engaging in the cost analysis of piping installation extends beyond the mere measurement of materials. Installations involving solar power systems require budgeting for various elements, including labor, materials, and potential long-term maintenance. Understanding short-term costs against the backdrop of long-term benefits can rationalize initial expenditure on higher-quality materials.

As the demand for renewable energy sources intensifies, investing in superior piping systems can yield efficiency gains that ultimately lead to cost savings. Informed financing strategies can allow a project team to estimate how various designs concurrently impact the bottom line. Emphasizing quality in installation and materials may lead to more substantial long-term savings as systems require less upkeep and perform at optimal efficiency throughout their lifespan.

Frequently Asked Questions

WHAT FACTORS INFLUENCE PIPE LENGTH FOR SOLAR SYSTEMS?

Multiple factors impact the required length of pipes in solar installations, including the layout of the building, the system type (solar thermal vs. photovoltaic), local regulations, and environmental conditions. Each of these aspects influences the determination of how much piping is needed. The junction of these variables creates a complex decision matrix. For instance, high-rise buildings require longer vertical runs, while flat rooftops may minimize horizontal distances. Meanwhile, strict regulations could limit the materials and techniques employed, further influencing overall lengths. Addressing each aspect in detail can lead to optimized piping strategies that reduce inefficiencies and ensure adherence to local codes.

HOW DOES BUILDING DESIGN AFFECT SOLAR PIPE INSTALLATION?

The design of a building plays a crucial role in the structure of the solar piping network. Architectural elements, such as height, layout, and intended energy usage, significantly influence how pipes are routed throughout the structure. Specifically, heights demand vertical placement, which can complicate installation and require longer piping. The internal layout may also dictate where the connected systems reside. Energy usage patterns in various sections of a building can lead to synergies or conflicts in piping layouts, making an innovative design beneficial for operational efficiency. Determining how to navigate these layouts early on leads to a more seamless installation process.

WHAT MATERIALS ARE IDEAL FOR SOLAR PIPING?

Choosing appropriate materials is essential for effective solar piping systems. Copper, PEX, and CPVC form the foremost materials, each possessing unique benefits and drawbacks. Copper is durable and excellent for thermal conductivity, while PEX offers flexibility and resistance to corrosion. CPVC is also resistant to high temperatures but still provides robust integrity. In selecting the right material, considerations such as cost, local temperature variations, and environmental resistance must drive decisions. The goal is to merge performance with financial viability to establish the most effective piping strategy for the solar system.

Summation of key points regarding the number of meters of pipes needed for a solar power installation on the 6th floor encompasses numerous crucial elements. The primary contributors to pipe length calculations are the layout of both the building and the solar system, local regulatory requirements influencing material choices, the environmental factors impacting durability, and the costs associated with materials and installation. Each of these factors requires thorough examination and analysis to minimize inefficiencies and optimize performance. A well-planned piping system ensures that solar installations function effectively for their intended purpose while adhering to relevant codes and regulations. Moreover, understanding the intricacies of material selection can lead to impactful long-term financial savings, making it a vital consideration for both current projects and future sustainability initiatives. Proper assessment, efficient design strategies, and responsible budgeting can streamline installations, ensuring a successful transition to renewable energy across various forms of building designs.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-many-meters-of-pipes-are-needed-for-the-6th-floor-of-solar-power/