To determine the optimal temperature range for solar thermal insulation barrels, 1. the ideal operating temperature generally lies between 60°C and 80°C, 2. maintaining these temperatures ensures efficient heat retention, 3. insulation quality is highly dependent on the material used, 4. proper design and installation significantly impact performance. The insulation efficiency varies depending on ambient conditions and the specific application of the barrel. For example, during colder months, it’s critical to maintain higher temperatures to ensure energy efficiency. Conversely, in warmer climates, it may be beneficial to allow the temperature to moderate to avoid excessive overheating, which could compromise the system’s integrity.

1. UNDERSTANDING SOLAR THERMAL INSULATION BARRELS

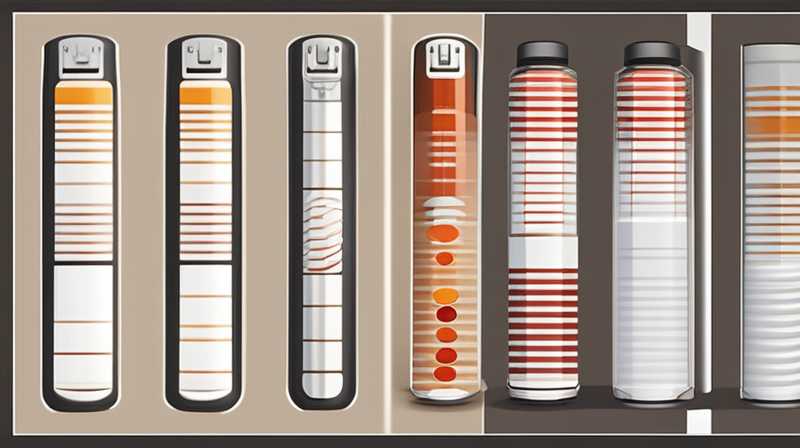

Solar thermal insulation barrels serve a vital role in the utilization of solar energy, particularly in applications such as heating water for residential use, swimming pools, and even industrial processes. In essence, these barrels capture solar energy and convert it into thermal energy, storing heat for future use. The materials employed in the construction of these barrels are engineered to optimize thermal retention and protect against environmental elements that could diminish their efficiency.

The construction of a solar thermal insulation barrel predominantly involves selecting high-quality insulation materials that facilitate minimal heat loss. Common materials include polyurethane, polystyrene, and fiberglass, which possess distinct thermal properties that contribute to the overall performance of the system. An understanding of how these materials interact with temperature changes is crucial in determining the best insulation practices and usage patterns.

2. OPTIMAL TEMPERATURE PARAMETERS

Determining the most advantageous temperature settings for solar thermal insulation barrels is paramount to optimizing system performance. Typically, the recommended operating parameters fall between 60°C and 80°C. Sustaining temperatures within this range allows for improved heat retention and efficient use of collected energy. When the temperature dips below 60°C, the efficiency of the heating process may decline, resulting in slower energy capture and increased reliance on auxiliary heating systems, which can lead to higher operational costs.

When reaching temperatures above 80°C, several factors come into play that can affect efficiency negatively. For instance, excessive heat can lead to thermal degradation of certain insulation materials or even cause release of excess energy into the environment rather than retaining it. Furthermore, addressing overheating issues might necessitate complex systems for cooling, which could counter the simplicity that solar thermal systems are designed to achieve.

3. INFLUENCE OF INSULATION MATERIALS

The choice of insulation material plays a crucial role in determining how well a solar thermal barrel retains heat. Polystyrene, for instance, is lightweight and easy to handle, providing a good balance of low thermal conductivity and reasonable compressive strength. This material is often utilized in settings requiring moderate insulation performance, making it suitable for residential applications.

Polyurethane foam, on the other hand, boasts superior insulation properties and minimal thermal conductivity. This makes it particularly appealing for high-performance solar thermal insulation barrels, especially in colder climates or regions with extreme temperature fluctuations. Its ability to maintain stable temperatures while preventing heat escape demonstrates its effectiveness in maximizing thermal energy retention.

The ongoing advancements in insulation technology can lead to significant improvements in the operational effectiveness of solar thermal barrels. Innovations continue to emerge, presenting a wide spectrum of options for manufacturers seeking to enhance energy efficiency. As the industry evolves, new materials and composites may prove vital in achieving enhanced thermal insulation capabilities.

4. DESIGN AND INSTALLATION CONSIDERATIONS

Beyond the materials used, the overall design of solar thermal insulation barrels significantly impacts performance. Proper design takes into account factors such as barrel size, shape, and integration of the solar heating system. A well-designed solar thermal barrel should allow for optimal exposure to sunlight while also minimizing heat loss through conduction, convection, and radiation.

Furthermore, installation techniques play an essential role in ensuring that the barrels function effectively. Misalignment, gaps, or incorrect sealing can lead to major losses in efficiency and effectiveness, thereby negating much of the investment made in high-quality materials. Engaging skilled professionals for the installation of these systems ensures that each component functions cohesively, prolonging equipment life and maximizing return on investment.

It is also crucial to assess local environmental conditions when designing and installing solar thermal insulation barrels. Geographic inferences can significantly influence energy collection and heat retention, necessitating tailormade solutions that address unique challenges presented by climate, altitude, and geographical features.

5. ENVIRONMENTAL IMPACTS AND EFFICIENCY

Operating solar thermal insulation barrels within the prescribed temperature range not only enhances energy capture but also contributes positively to the environment. Harnessing renewable solar energy reduces reliance on fossil fuels and minimizes greenhouse gas emissions, supporting sustainability initiatives globally. Furthermore, thermal storage systems provide a buffer for energy demands, enabling more efficient energy consumption patterns.

As awareness of climate change and environmental sustainability grows, the adoption of systems that efficiently utilize renewable resources continues to rise. By incorporating solar thermal technology into residential and commercial systems, communities can work toward achieving energy independence while simultaneously promoting environmental stewardship.

6. THE ROLE OF MAINTENANCE

Maintenance is another critical aspect of ensuring that solar thermal insulation barrels operate at peak performance. Regular inspections and appropriate upkeep extend the lifespan of the barrels and enhance their energy efficiency. For instance, cleaning the exterior surfaces prevents dirt buildup, which could hinder sunlight absorption and reduce overall thermal performance. Moreover, checking insulation integrity and seals can preemptively mitigate issues that could lead to significant energy loss.

User familiarity with the system’s operation can also aid maintenance efforts. Users should be educated on the optimal operational temperatures, indicators of potential problems, and best practices for maximizing energy efficiency. These proactive measures not only help secure energy savings but also contribute to the sustainability of the broader energy ecosystem.

FREQUENTLY ASKED QUESTIONS

HOW DO I DETERMINE THE BEST TEMPERATURE RANGE FOR MY SOLAR THERMAL INSULATION BARRELS?

The temperature range for solar thermal insulation barrels is typically optimal between 60°C and 80°C. To determine the best temperature for your specific installation, consider the following: 1. Evaluate your ambient environmental conditions. Areas with extreme cold may require higher temperature retention, while milder climates may function effectively at lower ranges. 2. Understand your system’s design features. Systems equipped with high-quality insulation can maintain higher temperatures with less energy loss. 3. Consult with local experts in solar thermal systems. Their experience and insights can guide you to make well-informed decisions tailored to your needs.

WHAT MATERIALS ARE IDEAL FOR INSULATING SOLAR THERMAL BARRELS?

When considering insulation materials for solar thermal barrels, polyurethane, polystyrene, and fiberglass are among the most effective options. Polyurethane exhibits superior thermal resistance properties, making it popular in regions where temperature fluctuations are frequent. Polystyrene is another cost-effective option that performs well in milder climates and applications. It is essential to select materials based on their thermal conductivity and compressive strength, taking into consideration the specific operating conditions and environmental challenges faced.

HOW CAN MAINTENANCE AFFECT THE EFFICIENCY OF MY SOLAR THERMAL SYSTEM?

Regular maintenance directly influences the efficiency of solar thermal insulation barrels. Proper upkeep allows for the timely identification and remedy of potential issues, such as loss of insulation integrity or dirt accumulation on surfaces. Neglecting maintenance may lead to diminished performance, increased energy losses, and eventual failures. Simply ensuring that insulation remains intact and that absorption surfaces are clean can significantly enhance heat retention. Users should also educate themselves on routine checks and inspections that can ensure the longevity and efficiency of their systems.

The utilization of solar thermal insulation barrels operates as an intersection of technology, design, and ecology, achieving significant energy savings while fostering environmental responsibility. The ideal temperature range, encompassing 60°C to 80°C, is instrumental in maintaining efficiency. The choice of insulation material, proper system design, and diligent maintenance practices are critical components that collectively determine operational excellence. Education on the appropriate handling and optimization of these systems cannot be overstated, as it empowers users to maximize their investments in renewable energy technology. By aligning these practices with environmental awareness, society can harness the full potential of solar thermal energy, paving the way for sustainable advancements in energy consumption.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-many-degrees-is-suitable-for-solar-thermal-insulation-barrels/