Determining bean storage capacity in a tank can depend on several factors, primarily regarding the tank’s dimensions and the type of beans intended for storage. 1. Tank capacity varies significantly based on the design and size, which determines how many beans can fit. 2. Different beans, such as kidney or black beans, have distinct physical characteristics that can affect the total quantity stored. 3. Environmental factors, such as humidity and temperature within the storage tank, play a crucial role in maintaining the quality of stored beans. 4. Comprehensive calculations must consider both the physical dimensions and the packing considerations of the beans for accurate predictions.

1. UNDERSTANDING BEAN STORAGE TANKS

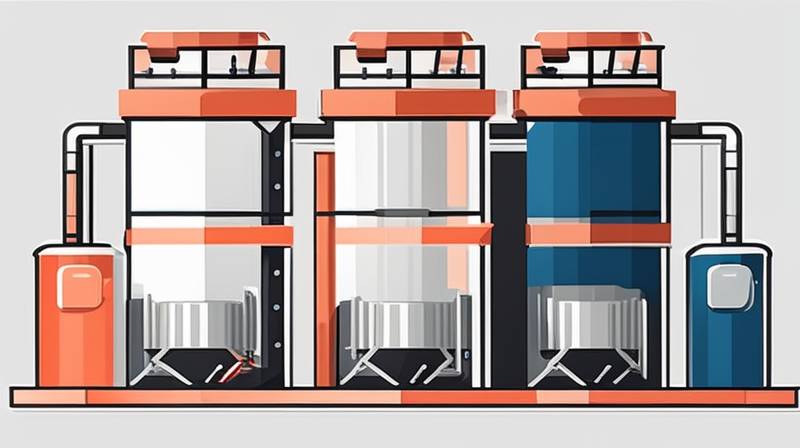

When examining the intricacies of bean storage, it’s essential to define what constitutes a bean storage tank. These containers are designed specifically for the preservation of various types of beans, ensuring optimal conditions to maintain their freshness and nutritional value. Typically, a bean storage tank can vary in size from small containers intended for home or retail use to large silos meant for agricultural applications. The selection of a storage tank depends largely on the quantity of beans that need to be preserved, as well as the logistics of how they will be used or sold.

Moreover, the regulations and standards associated with food storage must be adhered to, ensuring safety and compliance. Factors such as material composition of the tank, potential exposure to contaminants, and air circulation must be considered seriously. The design of the bean storage facility can significantly influence its effectiveness, especially regarding maximizing storage space while minimizing spoilage or waste due to environmental factors.

2. FACTORS AFFECTING STORAGE CAPACITY

The capacity of a bean storage tank is influenced by several key elements. The dimensions of the tank are critical as they directly correlate to the volume of beans the tank can hold. For instance, a cylindrical tank’s capacity can be calculated using the formula for the volume of a cylinder: V = πr²h, where ‘r’ is the radius and ‘h’ is the height. A larger tank in either dimension allows for a greater total bean storage. This fundamental understanding of geometry can help stakeholders determine bean quantities accurately.

Bean characteristics also play a pivotal role in determining capacity. Different varieties of beans – whether they are small like lentils or larger like fava beans – possess contrasting spatial densities, thus affecting how tightly they can be packed. As a rule of thumb, specific beans will occupy different volumes due to their unique shapes and sizes, which must be factored into any calculation related to bean storage capabilities. For instance, when densely packed, small beans can take up less space compared to larger varieties that might leave gaps, thereby reducing the total count of beans stored.

3. ENVIRONMENTAL INFLUENCES ON STORAGE

In addition to physical parameters, environmental factors play a significant role in the overall maintenance and longevity of beans in storage. Humidity is a crucial consideration, as excessive moisture can lead to mold growth or spoilage. Ideally, a bean storage tank should maintain a humidity level below 65% to prevent dampness. Additionally, the temperature inside the tank is equally vital; ideally, temperature ranges for optimal bean preservation should not exceed 70°F (21°C), as higher temperatures can accelerate spoilage processes and lead to significant losses in quality.

Ventilation is another important environmental aspect. Proper airflow within the storage tank can mitigate moisture build-up and help regulate temperature. This is particularly important for large-scale storage systems, where maintaining consistent conditions is often a logistical challenge. Failure to incorporate adequate ventilation can lead to pockets of stale air, promoting conditions conducive to spoilage. Regular monitoring of these environmental parameters is therefore crucial to ensure the integrity and longevity of stored beans.

4. PACKING CONSIDERATIONS

When determining how many beans can be stored in a tank, packing considerations are vital to consider. Packing efficiency refers to how beans are arranged within the storage tank. Beans can be packed tightly or loosely, and the packing method can vary based on the type of beans and the intended duration of storage. Understanding the optimal packing arrangement not only maximizes storage capabilities but also minimizes damage to the beans themselves.

For example, using a bulk storage approach that focuses on placing beans in larger quantities can yield a higher volume of beans in a tank. The objective should be to achieve the densest possible packing without compromising the structural integrity of the beans. A more sophisticated approach involves using methods such as palletizing or employing bins that inhibit physical damage while maximizing storage potential. Consistent evaluation and adjustment to packing methods can significantly improve storage efficacy.

5. CALCULATING STORAGE CAPACITY

The actual calculation of how many beans can be stored in a tank is derived from all the previous considerations: dimensions, bean characteristics, environmental influences, and packing considerations must be synthesized to arrive at a comprehensive answer. To illustrate this, consider a tank with a volume of 100 cubic meters. By determining the average volume of a single bean, one can derive the total number of beans that could theoretically fit in the tank under ideal packing and environmental conditions.

Assuming average kidney bean dimensions, calculating the total usable capacity might yield a figure that needs to be adjusted for air pockets and inherent imperfections in packing strategies. This mathematics can become complex when varied bean types are introduced into the equation, necessitating a fluid and detailed analysis of storage tank design and configuration.

The applications of this knowledge extend beyond simple calculation; it informs operational strategies and decisions surrounding bean procurement, marketing, and distribution in commercial operations.

6. RECOMMENDATIONS FOR OPTIMAL STORAGE

To ensure the longevity and quality of stored beans, several recommendations can help optimize storage strategy. Regular monitoring of environmental conditions within the storage tank, including temperature and humidity levels, can significantly improve overall outcomes. Implementing advanced technologies such as humidistats and thermometers can automate monitoring and allow for timely adjustments.

Additionally, periodic inspections of the stored beans themselves can identify early signs of spoilage or issues with packing. By conducting these inspections, one can address any problems before substantial losses occur.Developing a schedule for rotation of stock can also help maintain freshness and prevent exceeding the shelf life of older beans within the batch.

Finally, ensuring that the storage tank is manufactured from appropriate materials resistant to environmental hazards can further enhance quality and safety. Investment in proper technology for storing beans will ultimately yield greater returns in terms of quality and marketability, thereby benefiting the broader supply chain.

7. EFFECTIVE MANAGEMENT STRATEGIES

Management strategies surrounding bean storage should encompass a holistic approach that addresses supply chain aspects, warehouse organization, and staff training. Developing inventory management protocols will allow for more efficient tracking of stored beans and smoother transitions during procurement and sales. Harnessing software systems specifically designed for inventory tracking can provide insights into stock levels and turnover rates.

Moreover, fostering a culture of food safety and quality assurance among staff is vital. Training employees on best practices for handling and storing food products can mitigate risks associated with spoilage or contamination. Creating a clear set of operating procedures for both packing and unpacking beans can streamline operations, ensuring that quality and safety are prioritized consistently.

Engaging with stakeholders who possess expertise in food safety regulations can also enhance compliance and build trust with consumers who prioritize quality in their food sources. The successful management of a bean storage facility lies in the marriage of technology, human skill, and rigorous quality control.

FAQs

HOW IS THE CAPACITY OF A BEAN STORAGE TANK CALCULATED?

Calculating the capacity of a bean storage tank involves determining its physical dimensions, specifically its height and diameter. Using the volume formula for cylindrical tanks (V = πr²h) allows for the establishment of total volume in cubic meters. Subsequently, the volume of an individual bean must be computed based on its average size and shape. By dividing the total tank volume by the volume of one bean, an approximate quantity of beans that can be stored is achieved, which should take into account packing efficiency and potential air voids.

WHAT FACTORS INFLUENCE HYGROMETRIC CONDITIONS WITHIN THE TANK?

Hygrometric or humidity conditions inside a storage tank are influenced by several factors. Climate control systems must be properly maintained to ensure that temperature and moisture levels remain consistently within safe ranges. External environmental conditions, such as ambient humidity and temperature, can also impact the internal environment of the tank, as can the frequency with which the tank is accessed for loading and unloading beans. Ventilation plays a primary role in humidity levels; if there is inadequate air circulation, moisture may become trapped within the tank, creating a hospitable environment for mold or decay.

WHAT ARE THE BEST PRACTICES FOR PACKING BEANS IN STORAGE?

Achieving an optimal packing configuration for beans involves several best practices. Use uniform containers that can accommodate the spatial characteristics of various beans effectively. Ensuring that beans are packed tightly can prevent movement within the tank, diminishing the likelihood of breakage or spoilage due to shifting during transportation. Regularly rotating stock can help maintain freshness and reduce the risk of older beans being forgotten in favor of newer arrivals. Additionally, incorporating technological advancements, such as automated packing machines, could lead to more efficient use of storage space.

Ensuring optimal storage capacity for beans necessitates a comprehensive understanding of tank characteristics and external factors influencing the environment. It is crucial to address the design and specifications of the storage vessel, ensuring it accommodates a variety of beans without compromising quality. Analyzing storage dynamics, such as packing methods and volumetric calculations, further contributes to maximized capacity. Observing environmental conditions alongside implementing effective management strategies paves the way for maintaining the integrity of the beans over time. Stakeholders looking to optimize their bean storage operations must integrate multiple considerations: the types of beans, storage tank dimensions, environmental controls, and strategic inventory management. This level of detail ensures that bean storage does not just meet quantitative requirements but also safeguards the quality and freshness crucial to consumers. Ultimately, approaching bean storage with a framework that balances technical specifications with practical management strategies will lead to long-term success and sustainability within this sector.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-many-beans-can-a-bean-storage-tank-store/