The number of batteries in a 40-foot energy storage cabinet varies depending on the battery type, design, and energy capacity. 1. A typical configuration for lithium-ion batteries can include between 200 to 400 individual battery cells. 2. Different manufacturers may have unique modular designs, influencing the total count. 3. Several setups allow for flexibility in configuration based on intended usage. 4. Energy capacity also plays a pivotal role in determining the battery count, with higher capacities generally requiring more cells.

In energy storage systems, particularly when implementing large-scale installations like a 40-foot cabinet, the design intricacies and scalability must be addressed comprehensively. This article explores the significant aspects of battery placement in these robust energy systems, exploring various configurations and their implications for energy efficiency and deployment flexibility.

1. ENERGY STORAGE SYSTEM DESIGN

The design of an energy storage cabinet, particularly one measuring 40 feet, is an endeavor that spans several engineering and practical considerations. A fundamental aspect to understand is the energy demands that the system must meet. Energy storage cabinets are built to serve different purposes – from commercial to industrial capacities, each with distinct requirements that dictate the choice and number of batteries used in such configurations.

When considering the energy demand, the peak load requirements of the facilities being serviced must be calculated. In many scenarios, this demand fluctuates throughout the day, necessitating a system that can store energy efficiently during periods of low demand for usage during peak times. The total energy capacity of the storage system is core to determining how many batteries need to be integrated into the design.

Battery chemistry is another critical variable that influences the design and capacity of these systems. Lithium-ion batteries are the most prevalent option due to their high energy density and longevity. However, alternative chemistries such as lead-acid, nickel-cadmium, and flow batteries might be considered based on specific operational requirements or budget constraints. Each chemistry has its own volumetric and mass energy storage capabilities, further complicating the design of optimal storage capacities in a 40-foot configuration.

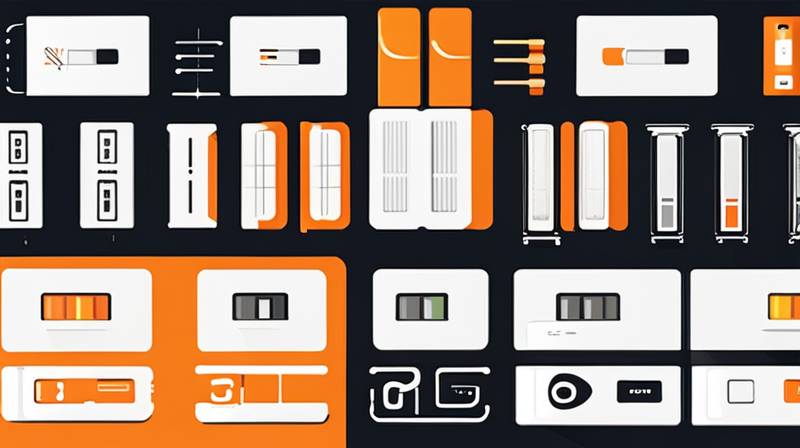

2. TYPES OF BATTERIES USED

A multitude of battery types can be utilized within a 40-foot energy storage cabinet, affecting the total number of batteries incorporated into the design. Lithium-ion batteries dominate the market, owing to their high energy density, low self-discharge rates, and extensive lifecycle. Within this category are several types, including lithium iron phosphate (LiFePO4), which offers enhanced safety profiles and longevity, and lithium nickel manganese cobalt oxide (NMC), known for its high energy capacity.

There are significant debates about whether lithium-sulfur batteries could prove beneficial in future designs due to their theoretical energy storage capabilities. Currently, these batteries are still under development but orchestrate the notion of increased storage density—potentially attracting interest based on future technology advancements.

Lead-acid batteries have also been a historically significant choice, particularly for applications needing substantial power in a short duration. While their energy density is lower than that of lithium variants, the reliability and established technology make them a staple for many energy storage systems. Furthermore, their recyclability and cost-effectiveness provide practicality where immediate deployment is necessary.

3. ENERGY CAPACITY AND CONFIGURATION

The energy capacity of a 40-foot energy storage cabinet is paramount in deciding the battery arrangement. Typical configurations might include arrangements that can support capacities between 500 kWh to several MWh, depending on use case scenarios. A higher capacity configuration may result in needing more battery cells due to the direct correlation between the total energy output and the number of batteries in series and parallel arrangements.

Battery configuration also influences how batteries are wired together to enhance overall performance and manage voltage levels effectively. For instance, in a series configuration, batteries increase the voltage output, whereas a parallel configuration bolsters the amp-hour rating, necessary for sustained energy demands over time. The expectation for real-time energy demands may call for a hybrid approach where both configurations coexist.

Energy management systems (EMS) also play a vital role in optimizing the performance of 40-foot energy storage cabinets. Implementing advanced control algorithms permits operators to maximize the efficiency of charging and discharging cycles, ensuring that the batteries operate within optimal parameters. These systems help mitigate performance issues associated with thermal environments, extending the life of individual batteries and the overall cabinet.

4. SCALABILITY AND MODULARITY

The scalability of energy storage cabinets, especially those of considerable size, is an essential aspect of modern energy strategies. Modularity allows for the accommodation of various energy demands and the flexibility to expand storage capacity as needed. Such designs enable operators to add or remove battery units based on changing energy requirements or advancements in technology without the need for complete system replacement.

Advanced modular designs often include rack-mounted battery setups, allowing for easier handling and maintenance. This design approach also facilitates the maintenance of batteries, enabling quicker troubleshooting and replacement of failing units without significant downtime to the system. Modular configurations may contribute to cost savings by offering the flexibility to replace only necessary units as opposed to entire stacks.

Furthermore, the implications of a modular design extend into the realm of technological advancements in energy storage. In an era marked by rapid developments in battery technology—such as quantum dots and advanced electrolytes—modular systems can embrace these innovations without extensive overhauls. Companies that thrive in the renewable energy space increasingly favor such systems, as they can adapt to new technologies as they emerge.

5. SAFETY AND REGULATORY CONSIDERATIONS

Safety remains a significant concern overseen in the design and deployment of large-scale energy storage systems. Regulatory standards and safety guidelines command all energy storage installations to comply with established regulations to protect users and property. Standards vary depending on jurisdiction, but they often encompass battery storage capacity, electrical installation codes, and ventilation systems to prevent potential hazards.

In particular, lithium-ion batteries require special considerations due to their reactive nature. Ventilation systems, fire suppression measures, and temperature controls are vital components in preventing overheating or thermal runaway situations that could catastrophically impact a 40-foot energy storage cabinet.

Regular inspections and adherence to guidelines are essential for reducing risks associated with storage systems. Many manufacturers provide recommended practices for installation and maintenance, which enhance safety and longevity. Additionally, training personnel in proper handling, emergency management, and maintenance routines contributes significantly to ensuring the reliability of energy storage systems.

6. BILL OF MATERIALS AND COST CONSIDERATIONS

A comprehensive bill of materials (BOM) entails all essential components for erecting a 40-foot energy storage cabinet. Understanding the total cost implications—including battery costs, chassis construction, electrical systems, and safety features—is fundamental for projects aiming for sustainability.

Battery costs can vary dramatically depending on chemistry, brand, and available subsidies. When aggregating these costs, it’s also necessary to consider additional ancillary components that will surely drive the overall expenditure. A detailed BOM allows for accurate budgeting and resource planning, essential in transitioning from ideation to project rollout.

Evaluating total ownership costs should also factor in maintenance, energy efficiency rates, and lifespan. Choosing the right battery chemistry is one pivotal factor in determining the economic viability of energy storage systems. Manufacturer warranties and lifecycle costs significantly impact long-term performance, making the selection typical not merely a matter of upfront pricing but overall fiscal responsibility.

FAQs

HOW CAN I DETERMINE THE NUMBER OF BATTERIES REQUIRED FOR A 40-FOOT CABINET?

Determining the number of batteries needed for a 40-foot energy storage cabinet involves analyzing several factors, including energy demand, capacity required, and battery type. The first step is to ascertain the total energy storage capacity, expressed in kilowatt-hours (kWh). Once this requirement is established, one can easily calculate how many batteries will be necessary. For example, if using lithium-ion batteries with a capacity of 200 Ah at 48 volts, this equates to approximately 10 kWh per battery. By dividing the total kWh requirement by the battery capacity, the required number of batteries can be determined. It’s also important to account for design flexibility, efficiency ratings, and potential future capacity increases, which could necessitate additional batteries in the system.

WHAT ARE THE COMMON TYPES OF BATTERIES USED IN ENERGY STORAGE CABINETS?

In energy storage cabinets, several common types of batteries are adopted based on specific requirements. The most popular are lithium-ion batteries due to their high energy density, longevity, and efficiency. Within this realm, variants such as lithium iron phosphate and nickel manganese cobalt oxide cater to different needs. Other types include lead-acid batteries, which are reliable yet have lower energy density and shorter lifespans. Additionally, emerging options like flow batteries, based on aqueous solution chemistries, are gaining traction for their scalability. Ultimately, the chosen battery type depends on intended use cases, deployment scenarios, and budgetary constraints.

WHAT FACTORS IMPACT THE COST OF A 40-FOOT ENERGY STORAGE SYSTEM?

Several factors critically influence the overall costs of a 40-foot energy storage system. The primary components include the battery types selected, which greatly affect upfront capital costs and lifecycle expenses. Additional elements such as casing, structural components, electrical systems, safety installations, and control systems contribute to the total expenditure. Furthermore, the energy management systems required for optimizing battery use and safeguarding performance can impose ongoing costs. Labor costs for design, installation, and long-term maintenance should also be accounted for, as these can lead to significant variations in total ownership costs. Finally, regulatory compliance and any applicable incentives or rebates can further influence the final cost calculations.

Batteries in a 40-foot energy storage cabinet can yield impressive outcomes, determined by considerations around types, configurations, efficiencies, and future expansion. The evolution of battery technologies and innovative designs signifies a moving tide that supports better energy management in the pursuit of sustainability. Many key elements lead into an understanding of how these robust systems function, and each energy storage project should take a systematic approach to design and implementation, ensuring it meets the specific needs of energy demands, safety, efficiency, and cost-effectiveness. Every detail contributes to creating an adaptable energy solution, setting the stage for transitioning into a cleaner, renewable energy future equipped with substantial storage capabilities.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-many-batteries-are-in-a-40-foot-energy-storage-cabinet/