When considering the specifics of an A storage battery protection board, it is essential to recognize a few fundamental aspects. 1. The count of such boards can vary depending on usage, determined by the battery setup and associated requirements. 2. These boards are integral for managing battery safety, which includes functions like overcharge protection, over-discharge protection, short-circuit prevention, and thermal regulation. 3. Selection of the appropriate battery protection board is crucial for longevity and efficiency, as mismatched specifications could result in poor performance or even hazardous situations. 4. The right balance between the number of cells and the protection setup is imperative, ensuring that compatibility and safety are maintained during operation.

1. UNDERSTANDING BATTERY STORAGE SYSTEMS

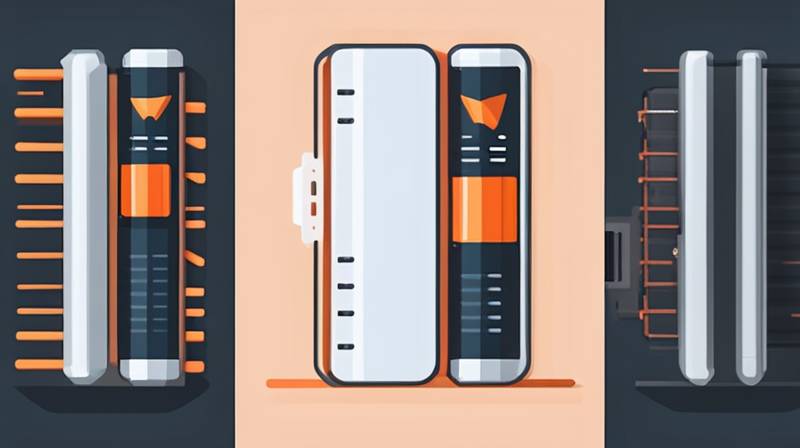

To truly grasp the significance of protection boards in battery storage, it’s advantageous to explore what a storage battery entails. Batteries serve as devices that convert stored chemical energy into electrical energy. The comprehensive functionality of these batteries relies heavily on the presence of a protection board. The protection board’s role encompasses safeguarding the cells from conditions that could lead to malfunction or safety hazards.

Protection boards are designed to monitor critical parameters, such as voltage and current levels. These components maintain an optimal operating range to guarantee the longevity of the battery. When the battery exceeds its designated limits, the protection board activates to mitigate risks. Understanding these intricacies provides insight into the intricate mechanisms that ensure battery reliability and safety. The number of protection boards also depends on the architecture of the battery system under consideration.

2. COMPONENTS AND FUNCTIONS OF PROTECTION BOARDS

Unpacking the components and functionalities of battery protection boards reveals their essential contribution to efficient power management. The typical protection board integrates various electronic components, each serving a unique purpose. These components include voltage sensors, current sensors, and microcontrollers.

Voltage sensors are critical in ensuring that the individual battery cells do not exceed their voltage thresholds. Overcharging can lead to excessive heat and potential explosion, emphasizing the need for protective measures. Current sensors monitor the flow of electricity, which is vital for preventing over-current situations that could damage the battery and connected devices.

Microcontrollers play a vital role in processing the data gathered from sensors. They execute safety protocols established through software, responding to abnormalities promptly. These boards are not one-size-fits-all; each configuration must be tailored to the specific energy storage application and the number of cells in use. This complexity underscores the importance of correctly designing and implementing protection boards.

3. TYPES OF BATTERY PROTECTION BOARDS

Delving deeper into the realm of battery protection boards reveals several categories, each suited for different applications. Battery protection boards can be broadly classified into several types based on their functionalities and specifications.

One prevalent form is the BMS (Battery Management System), which serves both protective and management roles, monitoring the entire battery pack’s health. This system is crucial for lithium-ion batteries, which require sophisticated management to optimize performance and safety. BMSs oversee charge cycles, discharge cycles, temperature regulation, and cell balancing, ensuring that every cell operates within its safe limits.

Another type encompasses standalone protection boards, which function primarily to prevent overcharging, over-discharging, and short-circuits. Unlike BMSs, these boards may lack the comprehensive management features needed in larger or more complex battery systems. They can be more cost-effective and are suitable for smaller setups, such as individual battery cells or limited-use scenarios. Assessing the specific application’s requirements can guide the selection of the appropriate board type.

4. SELECTION CRITERIA FOR BATTERY PROTECTION BOARDS

Choosing the optimal protection board hinges on several vital factors. First and foremost, understanding the battery chemistry is essential. Lithium-ion, lead-acid, and nickel-metal hydride batteries all have unique requirements that dictate the type of protective measures necessary. For instance, lithium-ion batteries often necessitate precise voltage and temperature regulation due to their sensitivity to these parameters.

Secondly, the configuration of the battery pack—whether it is in series or parallel—affects the board’s design. In series connections, voltage increases while the capacity remains the same, necessitating a different approach compared to parallel connections, which boost overall capacity. This configuration will determine how many cells are monitored by the protection board and how they are wired together.

Lastly, understanding the power requirements of the devices the battery will serve is crucial. If a battery needs to support high-drain devices, the chosen protection board must accommodate higher currents and ensure appropriate thermal management. Hence, comprehensively evaluating power needs, cell chemistry, and configuration will yield the best performance and safety from the batteries employed.

5. THE SIGNIFICANCE OF PROTECTIVE MEASURES

The necessity of protective measures in battery systems cannot be overstated. Numerous incidents have occurred due to battery management failures that resulted in catastrophic outcomes. A robust protection board is not merely an accessory; it is a crucial component that mitigates risks associated with battery use.

For example, battery overcharging can lead to thermal runaway, a condition where the battery generates heat uncontrollably. This scenario typically arises when there is a failure in overcharge protection mechanisms. Additionally, short-circuits not only endanger the battery but can pose serious risks to both devices powered and users.

Moreover, effective temperature management is essential for maintaining battery integrity. Batteries perform optimally within a specified temperature range; deviations can impact efficiency and longevity. Protection boards equipped with thermal sensors can activate cooling mechanisms or provide warnings to prevent overheating. Thus, these protective measures are indispensable in promoting safe interactions with energy storage systems.

6. ADVANCEMENTS IN BATTERY PROTECTION TECHNOLOGY

Technological advancement has significantly impacted how battery protection systems are designed and implemented. Recent innovations include the integration of smart technology, facilitating real-time monitoring and data collection via IoT (Internet of Things) applications. This capability allows users to track battery performance metrics remotely and receive alerts for any anomalies that may arise.

Furthermore, modern protection boards are being engineered to utilize machine learning algorithms. These algorithms can predict potential failure modes based on historical data, optimizing the timing and nature of maintenance activities. As battery technology continues to evolve, with the introduction of solid-state batteries and other novel chemistries, protection boards will undoubtedly adapt to meet new challenges. This proactive approach enhances safety, efficiency, and battery lifespan substantially.

7. REGULATORY STANDARDS AND SAFETY COMPLIANCE

Battery protection boards must adhere to various regulatory standards to ensure safety and usability. Organizations and agencies establish numerous guidelines for battery manufacturing and usage, emphasizing the importance of compliance. Knowing these regulations helps manufacturers design boards that not only deliver optimal performance but also meet safety requirements.

For instance, UL standards dictate rigorous testing and certification processes. Boards that comply with these standards receive certification that assures consumers of their efficacy and safety. Additionally, international regulations, such as IEC standards, facilitate trade and ensure that products meet global safety expectations. Manufacturers who commit to adhering to these standards can instill greater confidence in their products, promoting stability in the marketplace.

FAQs

WHAT IS A BATTERY PROTECTION BOARD?

A battery protection board is an electronic circuit that safeguards rechargeable batteries, particularly lithium-ion types, against hazardous conditions such as overcharging, over-discharging, and short circuits. These protections are vital for ensuring the battery’s longevity, safety, and efficient performance. In addition to these critical protective tasks, such boards can also include features for balancing cell voltages, which is essential for maximizing overall battery performance and ensuring uniform discharge across all cells. By monitoring voltage levels in real-time, the board can prevent individual cell damage, significantly enhancing safety and efficiency. Overall, a robust protection board is indispensable for advanced battery applications, especially where safety and reliability are paramount.

HOW DO I CHOOSE THE RIGHT PROTECTION BOARD FOR MY BATTERY?

Selecting the appropriate protection board requires a careful assessment of multiple factors. First, one must consider the battery chemistry involved, as different types—like lithium-ion, nickel-metal hydride, or lead-acid—necessitate distinct handling and protection measures. Next, evaluate the battery’s configuration, whether in series or parallel, as this dictates how voltage and current are distributed across cells. Additionally, one must assess the power needs of the devices that the battery will serve; high-drain applications will necessitate a board capable of supporting more substantial currents and ensuring adequate thermal management. Compatibility with the battery pack’s voltage rating is also crucial to prevent performance issues. Thorough research and potentially consulting with a specialist can help pinpoint the best solution tailored to the specific requirements.

WHAT ARE THE CONSEQUENCES OF NOT USING A PROTECTION BOARD?

Operating a battery system without an appropriate protection board can lead to dire consequences. The foremost risk involves potential overcharging, which can precipitate thermal runaway, resulting in battery swelling, leakage, or even explosion. Similarly, the absence of safeguards against over-discharging may result in irreversible damage to the battery cells, drastically reducing their lifespan and functionality. Additionally, without short-circuit protection, the risk of fire or electric shock increases significantly, endangering users and associated devices. Beyond safety dangers, the lack of cell balancing can yield imbalanced cells, resulting in reduced overall capacity and performance. Consequently, neglecting battery protection can culminate in financial loss, safety hazards, and operational failures, proving that protective measures are not just beneficial but essential for any battery-operated system.

SIGNIFICANCE OF BATTERY PROTECTION BOARDS

Battery protection boards embody an integral aspect of energy storage systems that ensures safety, efficiency, and longevity of batteries. By engaging in a thorough understanding of protection boards and their functionalities, one can significantly mitigate the risks associated with battery operations. The diverse range of boards available—ranging from sophisticated battery management systems equipped with intelligent features to simpler standalone units—validates the market’s need for precision in energy management.

As technology advances and the demand for higher efficiency power solutions escalates, the role of these protective components becomes even more significant. With an increasing reliance on portable and renewable energy solutions, the application of effective battery protection strategies is paramount. The consequences of neglecting effective battery management are severe and could pose hazards that could easily be prevented with prudent design and implementation of protection measures.

By understanding the complexities surrounding battery protection boards, their functionalities, and their significance in the contemporary energy landscape, stakeholders can make informed decisions. Ultimately, safeguarding one’s energy storage systems will lead to enhanced operational reliability, safety, and performance, translating into more efficient use of resources and greater satisfaction for end-users. As the energy paradigm shifts, the foundational knowledge of battery protection will continue to evolve, fostering innovation and securing a sustainable future for energy systems worldwide.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-many-a-storage-battery-protection-board/