1. A solar solenoid valve can last between 5 to 10 years, depending on the quality of the valve, environmental conditions, maintenance practices, and usage frequency. For instance, high-quality solenoid valves constructed from durable materials like brass or stainless steel tend to have a longer lifespan compared to those made from lower-grade materials. 2. Regular maintenance, such as the cleaning of the valve and ensuring proper installation, further enhances longevity. 3. Additionally, exposure to extreme weather conditions, like excessive heat or moisture, can negatively affect the valve’s functionality, leading to premature failure. 4. Overall, user habits, like how often the valve is activated, also play a crucial role in determining its longevity.

UNDERSTANDING SOLAR SOLENOID VALVES

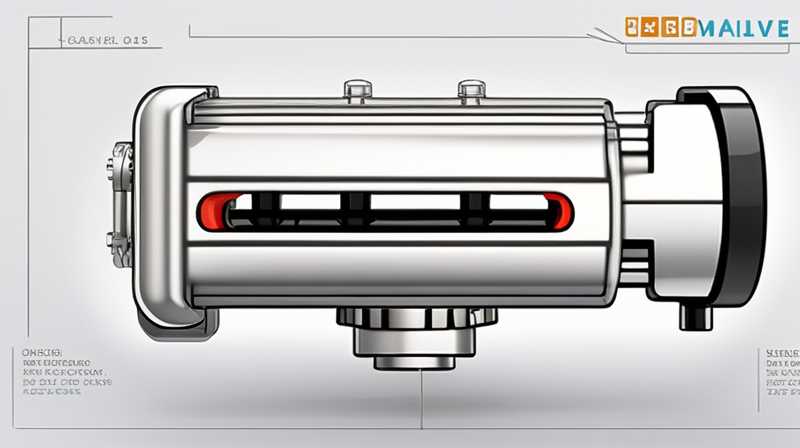

Solar solenoid valves serve as crucial components in various irrigation and plumbing systems, providing automated control over water flow based on solar energy mechanics. These ingeniously designed devices rely on an electromagnet to regulate the opening and closing of water lines. Recognition of the valve’s potential longevity hinges on several factors, each contributing to project success and sustainability. Hence, examining these facets becomes essential for anyone considering such technology.

The operational principle of solar solenoid valves is elegantly straightforward. With the introduction of electrical energy derived from solar panels, the solenoid coil becomes energized, producing a magnetic field. This magnetic field overcomes the opposing spring force, allowing the valve to open, thereby permitting water to flow. When power ceases, the spring returns the valve to its initial closed state. This mechanism is not only efficient but ecologically conscientious, aligning perfectly with contemporary environmental priorities.

FACTORS INFLUENCING LIFESPAN

MATERIAL QUALITY

The caliber of materials utilized in solar solenoid valves plays a pivotal role in their overall lifespan and reliability. Components manufactured from premium materials such as brass, stainless steel, or high-grade polymers demonstrate resilience against corrosion and environmental wear. In contrast, valves constructed from lower-tier materials often succumb to damage from rust, UV radiation, and other destructive elements more quickly.

Low-cost solenoid valves, while initially appealing due to their price point, frequently fail to stand the test of time. Their susceptibility to wear can result in malfunctions or leaks, ultimately necessitating premature replacements and incurring unexpected expenses. Therefore, users must assess the material specifications thoroughly before selection to ensure that their investment leads to long-term functionality.

INSTALLATION PRACTICES

Correct installation can drastically influence a solar solenoid valve’s operational lifespan. When improperly fitted or positioned, these devices may encounter undue stress, leading to wear or premature failure. It is crucial to follow manufacturer guidelines meticulously during installation, emphasizing proper torque specifications and alignment.

Inadequate sealing can also play a role, introducing leakage. This leakage not only leads to wasted resources but can introduce contaminants into the system. Building a robust connection, free of gaps, ensures that the valve operates efficiently and extends its longevity. Engaging professional installers with relevant experience can mitigate risks associated with personal errors and greatly improve the lifespan of the valve.

COMPATIBILITY WITH SYSTEMS

SYSTEM DESIGN AND APPLICATIONS

Solar solenoid valves often function within intricate irrigation or plumbing setups. It is paramount that users know and understand the system’s specifications in which the valve will operate. Using a valve that is mismatched in size or pressure rating could lead to failures or inefficient functioning.

In addition, the applications for which the valve is intended can significantly impact its lifespan. Continuous operation versus intermittent use carries different stress levels on the components. For instance, valves utilized in garden irrigation systems witnessing seasonal operation tend to last longer than those functioning in constant flow systems, where they may face more wear.

ENVIRONMENTAL CONDITIONS

Environmental factors undeniably affect the longevity of solar solenoid valves. Regions subjected to extreme temperatures, high humidity, or abrasive particles can significantly compromise performance. High heat can lead to component degradation, while freezing temperatures can disrupt fluid flow within the system.

Additionally, exposure to corrosion-inducing elements, such as saltwater in coastal areas, can severely diminish valve life. Users must consider these conditions when selecting a valve. Manufacturers often provide ratings for resistance to environmental factors, enabling buyers to make informed decisions.

MAINTENANCE ROUTINES

REGULAR INSPECTIONS

Establishing a consistent maintenance routine fosters the longevity of solar solenoid valves. Regular inspections can identify wear or malfunction before they escalate into serious issues. Tightening loose fittings, clearing debris, and inspecting seals for wear are all preventative measures that can prolong lifespan drastically.

A preventive maintenance approach reduces overall costs and downtime in irrigation systems by ensuring that each component operates efficiently. Users should document these inspections to track performance and address anomalies or concerns in a timely manner.

CLEANING PROCEDURES

In addition to regular inspections, maintaining cleanliness around the valve contributes significantly to functionality. Debris, dirt, and mineral buildup can impede valve operation, leading to erratic performance. Utilizing gentle cleaning agents to remove deposits without compromising the material is essential.

Moreover, users should ensure that the valve remains free from obstructions, particularly in outdoor contexts where environmental factors play a pivotal role. A direct approach to cleanliness results in enhanced operational effectiveness and extends valve life expectancy.

USER HABITS AND USAGE FREQUENCY

OPERATING CONDITIONS

The habits of individuals utilizing solar solenoid valves markedly impact their efficiency and longevity. For example, frequently turning the valve on and off can lead to increased wear and tear. While occasional use is generally permissible, a habit of repetitive operation can generate excess stress on the valve’s components.

Understanding operating patterns allows users to devise strategies promoting an extended lifespan. Users who can schedule their valve operations intelligently minimize wear and promote durability, ensuring equipment continues to perform optimally over time.

EDUCATION ON SOLAR TECHNOLOGY

Furthermore, educating users about solar technology is integral to maximizing efficiency. Awareness regarding system capabilities, limitations, and proper usage can significantly impact longevity. By leveraging resources and seeking guidance on maintenance, users can build a sustainable habit around their solar solenoid valves.

Understanding the technological aspects empowers individuals to utilize their systems more effectively, preventing premature issues from arising while ensuring that equipment operates at peak performance.

FAQs

WHAT CAUSES SOLENOID VALVEN TO FAIL EARLY?

Several factors can precipitate premature failures of solar solenoid valves. First, low-quality materials often introduce vulnerabilities to corrosion and mechanical fatigue, undermining durability. Moreover, improper installation can create excessive strain, leading to malfunction over time. Environmental elements like extreme heat, humidity, or corrosive conditions also contribute significantly. Regular maintenance that includes checks for wear and leaks ensures functionality remains intact as valves age. Users must prioritize these factors to maximize lifespan and avoid costly replacements. Additionally, consistent monitoring of valve connections allows for swift identification of issues. A combination of high-quality components, meticulous installation, and dedicated maintenance ultimately fosters sustainability.

HOW CAN I EXTEND THE LIFESPAN OF MY VALVE?

Extending the lifespan of a solar solenoid valve involves a comprehensive approach incorporating quality, installation practices, and vigilant maintenance. Begin by selecting high-quality materials known for their resilience and durability, as this underpins robust performance. Adhering strictly to manufacturer’s recommended installation guidelines mitigates unnecessary stress, ensuring that the valve operates efficiently. A consistent routine of inspections and proactive cleaning significantly enhances component longevity. By tracking maintenance records, users can identify potential issues promptly and mitigate further damage. Lastly, fostering awareness of operational patterns and ensuring smooth usage habits optimizes the valve’s operational efficiency, ultimately prolonging its service life.

HOW OFTEN SHOULD I CHECK MY VALVE?

The frequency with which one should check a solar solenoid valve hinges on several factors, including usage levels and environmental conditions. For systems in regular operation, conducting inspections every few months is advisable. On the other hand, in seasonal applications, inspections at the start and end of each operating season can suffice. Regular checks should encompass all connections, seals, and operational functionality, ideally paired with cleaning to remove any debris. In environments prone to extreme conditions, more frequent assessments are recommended to ensure ongoing performance. By prioritizing these routines, users will significantly reduce the risk of unexpected failures and elevate overall system reliability, ensuring optimal functionality.

The performance of a solar solenoid valve is a multifaceted subject influenced by quality, surroundings, and operational habits. Attention to material quality, installation techniques, environmental factors, and regular maintenance are critical for maximizing longevity. Users must engage in proactive inspections and cleaning, alongside understanding their systems’ specifications for ensuring durability. By making informed choices regarding user habits and educating themselves about the technology, individuals can ensure that their solar solenoid valves serve effectively for extended periods. Ultimately, adopting a comprehensive approach to valve management will yield better results, prolonging functionality with each passing season. Therefore, investing the necessary time and resources into this essential aspect of irrigation or plumbing systems is crucial for achieving long-term sustainability and operational effectiveness.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-long-will-the-solar-solenoid-valve-last/