1. The duration for a solar booster pump to shut down varies based on several factors including, system design, environmental conditions, and operational settings, typically ranging from a few minutes to several hours. Understanding these dynamics provides valuable insight into optimizing the pump’s performance and efficiency. 2. The pump’s ability to manage power consumption efficiently will influence shutdown times, particularly during low solar irradiance periods. Ratios of energy produced versus the demand placed on the system can create delays in shutdown. 3. Effective maintenance can also play a role in ensuring that the pump operates optimally and achieves the necessary shutdown times. Regular checks and timely interventions promote sustainability and reliability. 4. Understanding these aspects enables users to anticipate potential delays and enhance overall system management.

1. SYSTEM DESIGN

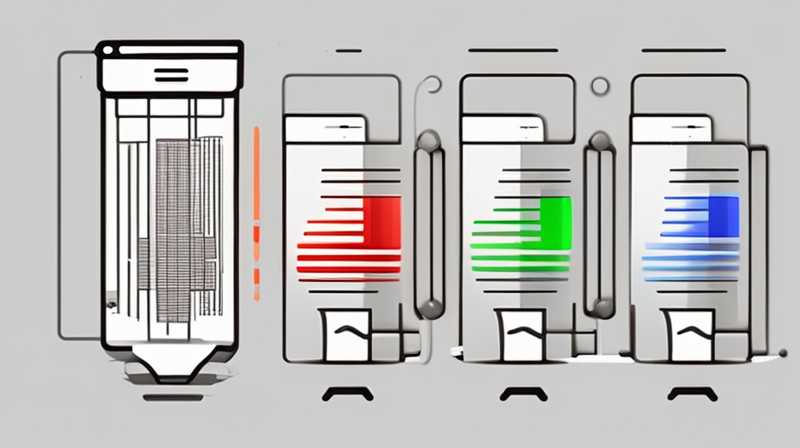

The blueprint of any standalone solar pump system substantially influences its operational efficiency and shutdown time. The overall design encompasses several components including the solar panels, pump motor, control systems, and storage tanks. Each element plays a vital role, thus forming a comprehensive network that affects the responsiveness of the pump.

Solar panels can vary in type and efficiency ranking; these variations lead to differing power outputs. A system utilizing high-efficiency panels will collect energy more rapidly and will more promptly reach sufficient levels to operate. Conversely, a design featuring outdated or lower-quality panels may prolong the pump’s operational phase and delay its shutdown. In essence, evaluating the solar panel specifications can elucidate the potential duration for which the pump remains in operation.

Equally, the configuration of the pump’s motor affects the functional output. Variable speed motors, unlike fixed-speed models, can adjust their performance based on real-time energy input. This adaptability can significantly reduce the duration before a shutdown occurs, particularly in environments where sunlight fluctuations are prevalent. Furthermore, control systems programmed for intelligent operation enhance the system’s ability to manage its energy use efficiently, thus hastening the shutdown time in response to declining solar power.

2. ENVIRONMENTAL CONDITIONS

The geographical setting and weather patterns have substantial impacts on how quickly a solar booster pump can cease its functions. Conditions such as shading from nearby structures or trees, temperature variations, and cloud cover can greatly shape the energy produced by the solar panels.

In environments where cloud cover is common, the solar panels receive diminished sunlight exposure, which can significantly reduce their energy output. This limited capacity may lead to an unwanted extension of the pump’s runtime, resulting in delays before complete shutdown. Consequently, the geographical layout—including the orientation and angle of the solar panels—should be strategically planned to mitigate adverse conditions.

Temperature also plays a critical role in the effectiveness of solar power generation. Most photovoltaic panels experience decreased efficiency as temperatures rise. However, warmer conditions can enhance the pump’s robustness and performance temporarily, allowing it to function longer before it needs to shut down. Knowledge of local climatic norms can aid users in making informed decisions regarding system setup and anticipating potential shutdown durations.

3. OPERATIONAL SETTINGS

The manner in which a solar booster pump is controlled influences its operational behavior, including how swiftly it can shut down. Users can establish distinct settings based on water demand, and these settings can differ based on time, season, or specific agricultural needs.

Many systems incorporate timers or smart controls that dictate the pump’s operation based on historical usage patterns. These automated solutions reduce human error while facilitating a more responsive shutdown process. Establishing operational settings requires a comprehensive understanding of both the environment in which the pump will function and the demands of the irrigation or water supply system it supports.

Conversely, neglecting to optimize these settings can lead to inefficiencies that contribute to extensions in operational duration. Manual adjustments may require more hands-on involvement, leading to delays in ceasing capabilities due to human oversight. Therefore, thorough education on how to create effective operational settings ultimately promotes prompt shutdown when needed.

4. MAINTENANCE AND MONITORING

Adequate maintenance routines greatly enhance the performance of a solar booster pump, including its ability to effectively shut down when required. Regular inspections, cleaning, and component servicing help identify potential issues before they exacerbate. These measures ensure that the system runs smoothly and that energy consumption remains at optimal levels.

Monitoring can be achieved through various advanced systems, allowing operators to receive real-time data regarding pump performance and energy production. Such insights enable users to foresee any potential issues or inefficiencies that could delay shutdown. Furthermore, incorporating technologies such as sensors and alarms can provide alerts when the pump should be disabled, enhancing operational fluidity.

Neglecting maintenance can result in unforeseen mechanical failures or increased energy burden, all of which can lead to extended periods of operation before shutdown. Therefore, establishing a regular maintenance schedule, alongside proper monitoring techniques, proves beneficial not only for immediate functionality but for long-term efficiency.

5. SYSTEM AGE AND TECHNOLOGY

An often overlooked aspect that influences the shutdown time of a solar booster pump is its age and the technology utilized within its design. Older systems, often composed of outdated components, may not function as effectively as their modern counterparts. This inefficiency can result in prolonged operation times when conditions shift.

Technological advancements in energy management and solar power systems continuously enhance performance metrics. Newer pumps and solar panels are often designed with improved efficiency ratings and noise-reduction capabilities. Consequently, they typically provide a faster response to energy fluctuations, allowing for quicker shutdown processes. Users could benefit significantly from assessing newer technologies, particularly if their existing systems are nearing end-of-life phases.

Investing in modern systems should be weighed against the costs of maintaining older equipment. A cost-benefit analysis will provide clarity on whether updates or replacements are worthwhile in the context of shutdown efficacy. Furthermore, keeping abreast of industry trends and advancements can foster better decision-making regarding the lifespan and reliability of the installed solar pump system.

6. COLLECTIVE FACTORS

It is essential to recognize how multiple factors intertwine and collaborate to determine the overall efficiency and response times of a solar booster pump. Understanding interactions between each component can lead to a more nuanced grasp of potential shutdown durations. For instance, environmental conditions directly affect the system’s design and operational settings, which in turn influence maintenance scheduling and technology advancement.

Optimizing a solar pump requires a holistic view, as decision-making benefits from a comprehensive assessment of how these elements coexist. Implementing a strategy that takes all elements into consideration can lead to elevated performance, and therefore shorter operational durations.

Adopting a tailored maintenance approach, leveraging technology advancements, and remaining attentive to environmental changes can significantly reduce unnecessary operational periods, achieving efficient and timely shutdowns. Ultimately, becoming well-versed in the interconnected nature of these elements is vital for anyone aiming to maximize their solar pump operations.

FREQUENTLY ASKED QUESTIONS

WHAT FACTORS INFLUENCE THE SHUTDOWN TIME OF A SOLAR BOOSTER PUMP?

Several factors impact how quickly a solar booster pump can shut down. 1. System design plays a major role as higher-quality components are often more responsive. 2. Environmental conditions, such as sunlight availability and temperature, also drive the system’s performance. 3. Operational settings, determined by user preferences and historical demand, must be optimized to ensure timely shutdowns. 4. Maintenance practices affect overall performance; neglect can hinder efficiency. Thus, recognizing and proactively managing these facets is critical.

HOW CAN I OPTIMIZE MY SOLAR BOOSTER PUMP FOR QUICKER SHUTDOWN TIMES?

To achieve a faster shutdown, begin with regular maintenance to ensure all components are performing optimally. Adjust your operational settings based on actual water usage and environmental factors, ensuring your pump trip schedule aligns with solar performance. Consider employing advanced monitoring systems that offer real-time data to pinpoint inefficiencies in performance which could prolong operations. Most importantly, invest in quality components from the start, as better systems usually respond more effectively, leading to quicker shutdown sequences.

WHAT SHOULD I DO IF MY SOLAR BOOSTER PUMP IS TAKING TOO LONG TO SHUT DOWN?

If shutdown times exceed expectations, initiate a comprehensive system check. Start by inspecting solar panels for debris or shading issues that could be impairing energy production. Ensure that the electrical connections and control systems are functioning optimally. Evaluate your operational settings as they may need adjustment based on current water demands. Lastly, if the problem persists, consult a technician who can provide a specialized assessment, as professional guidance can uncover inefficiencies not visible during casual inspections.

Understanding how solar booster pumps operate and the determinants influencing their shutdown times is pivotal for maximizing efficiency and effectiveness. The interplay of system design, environmental conditions, operational settings, maintenance practices, and technological advancements all contribute significantly to this process. By assessing the numerous variables involved and applying best practices, users can optimize their systems for operational efficiency, ultimately leading to effective water management solutions. Adapting a proactive approach to maintenance, being mindful of environmental factors, and leveraging technology are essential steps. Consequently, this creates a results-oriented framework that not only enhances the performance metrics but promotes the long-term sustainability of investments. Education and awareness in control settings, along with continuous evaluation of system performance, enable users to navigate potential challenges effectively and minimize operational downtime. The cumulative knowledge of these factors is imperative for achieving timely and efficient shutdowns of solar booster pumps, establishing a solid foundation for the success of any water management initiative.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-long-does-it-take-for-the-solar-booster-pump-to-shut-down/