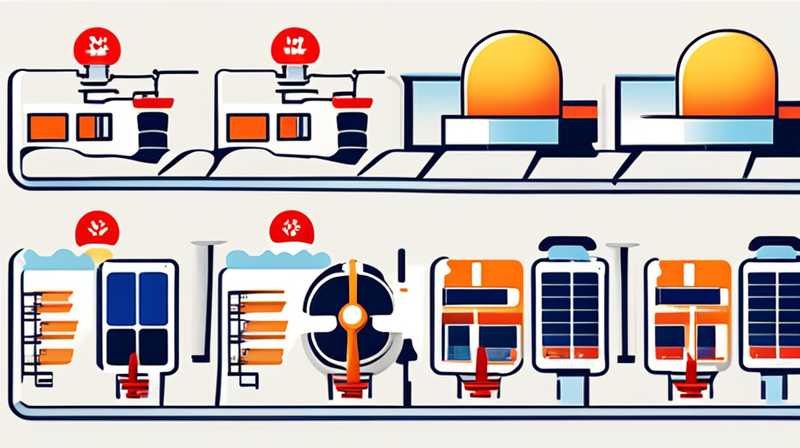

Factory solar power generation operates through a systematic process that involves multiple key steps. 1. Solar panels transform sunlight into electricity through photovoltaic cells. 2. The generated electricity is then fed into an inverter which converts direct current into alternating current suitable for factory equipment. 3. Energy storage systems, such as batteries, may be employed to ensure a steady power supply even when sunlight is insufficient. 4. Furthermore, efficiency is enhanced through careful positioning of solar panels and maximizing available light exposure. By employing these mechanisms, factories can harness renewable energy, thereby reducing reliance on fossil fuels and lowering operational costs.

1. INTRODUCTION TO SOLAR POWER IN MANUFACTURING

The integration of solar power within factories represents a significant shift in energy consumption paradigms. Traditionally reliant on fossil fuels, many manufacturing units have begun to transition toward renewable energy sources, with solar energy being at the forefront of this movement. This transition is not merely an environmental consideration but also an economic strategy aimed at reducing overhead costs and ensuring a sustainable future.

Solar power systems, particularly in factory settings, operate through complex mechanisms designed to harness the sun’s energy effectively. Understanding how these systems function allows stakeholders to appreciate their benefits fully. In essence, factory solar power generation can be dissected into several integral components, each playing a pivotal role in energy production. By comprehending these components, manufacturers can optimize their energy strategies for maximum efficiency.

2. CORE COMPONENTS OF FACTORY SOLAR POWER SYSTEMS

2.1 SOLAR PANELS AND THEIR FUNCTIONALITY

Solar panels are the heart of any solar power generation system in a factory. They are composed of numerous photovoltaic cells that convert sunlight directly into electricity. When sunlight strikes the photovoltaic cells, it excites the electrons within the cells, causing them to flow and generate direct current (DC). The efficiency of solar panels can vary based on several factors, including materials used, technological advancements, and geographical positioning.

The fundamental types of solar panels include monocrystalline, polycrystalline, and thin-film. Monocrystalline panels are known for their high efficiency and space-saving design, offering optimal energy production in limited areas. On the other hand, polycrystalline panels are usually more affordable and efficient in larger installations, while thin-film panels are lightweight and flexible but generally offer lower efficiencies. Understanding these distinctions is critical for factories aiming to choose the most suitable solar technology.

2.2 INVERTERS AND THEIR ROLE IN ELECTRICITY CONVERSION

Once solar panels generate electricity, that power must be converted before it can be utilized in most factory machinery. This is where inverters come into play. Inverters serve to convert the direct current (DC) produced by the solar panels into alternating current (AC), which is the form of electricity used by most industrial equipment.

There are two main types of inverters: string inverters and microinverters. String inverters are connected to multiple solar panels in series, making them cost-effective for larger installations, while microinverters are attached to individual panels, allowing for better performance monitoring and optimization. The choice of inverter can significantly impact the overall system performance and reliability of power supply within a manufacturing environment.

3. ENERGY STORAGE SOLUTIONS AND THEIR SIGNIFICANCE

3.1 BATTERIES IN SOLAR POWER SYSTEMS

Employing energy storage solutions, particularly batteries, is becoming increasingly common in factory solar power systems. Batteries allow factories to store excess electricity generated during peak sunlight hours, making it available for use during periods of low sunlight or increased energy demand. This aspect of solar power generation offers significant advantages in terms of reliability and operational efficiency.

Different types of battery technologies are used, including lithium-ion, lead-acid, and flow batteries. Lithium-ion batteries are known for their high energy density and long cycle life, making them ideal for commercial applications. Lead-acid batteries, while cheaper, have a shorter lifespan and lower energy efficiency. Understanding the nuances of battery technologies is essential for manufacturers to select the appropriate storage solution that fits their energy requirements and budgetary constraints.

3.2 OPTIMIZATION OF ENERGY STORAGE

In conjunction with the deployment of battery systems, optimization strategies are essential for maximizing utility. Advanced energy management systems can monitor energy consumption patterns and charge or discharge batteries accordingly. This approach not only improves energy efficiency but also extends the lifespan of the batteries by preventing excessive cycling and maintaining optimal state-of-charge levels.

Predictive analytics and machine learning are increasingly being integrated into these systems to forecast energy needs and automate peak load shifting, further enhancing cost-effectiveness. The implementation of these technologies provides a sophisticated layer to factory energy operations, ensuring that power generation aligns seamlessly with production schedules and downtime requirements.

4. EFFICIENCY ENHANCEMENT METHODS

4.1 PROPER POSITIONING OF SOLAR PANELS

The placement and orientation of solar panels are vital factors that drastically influence power generation efficiency. Optimal positioning involves considerations such as latitude, potential shading from surrounding structures, and seasonal sun paths. Ideally, solar panels should be tilted at an angle that allows for the highest exposure to sunlight throughout the year.

Conducting a solar site analysis that takes into account local weather patterns, geographical features, and time-of-year variations can substantially improve a factory’s solar output. In addition, tracking systems that follow the sun’s trajectory can be employed. These systems maximize light exposure by adjusting the panel angle as the sun moves across the sky, resulting in increased energy production relative to static systems.

4.2 MAINTENANCE AND MONITORING OF SOLAR SYSTEMS

Regular maintenance is paramount for sustaining the functionality and efficiency of solar power systems. Dust, debris, and environmental factors can hinder energy production. Therefore, implementing a comprehensive maintenance plan is essential. This could include scheduled cleanings, inspections of electrical connections, and monitoring of panel conditions.

Moreover, modern monitoring systems provide real-time data on energy production and potential issues within the solar power infrastructure. These systems allow for proactive interventions, thereby minimizing downtime and maximizing productivity. Effective oversight ensures that factory solar operations run smoothly and efficiently, enabling businesses to fully capitalize on their investment in renewable energy.

5. FINANCIAL IMPLICATIONS AND INCENTIVES

5.1 COST OF IMPLEMENTATION

Transitioning to solar power entails a significant initial investment, encompassing the costs of equipment, installation, and potential site modifications. However, this upfront expense must be weighed against long-term financial benefits. Savings on electricity bills can be substantial over time, and the return on investment period is shortening as solar technology becomes more affordable.

The overall cost of installation can vary widely based on factors such as geographical location, type of solar system, and available incentives. Many governments provide tax credits, rebates, and grants targeted at encouraging renewable energy adoption, which can significantly offset initial costs for manufacturing entities.

5.2 LONG-TERM FINANCIAL BENEFITS

Beyond reduced electricity costs, factory solar power systems can enhance a company’s reputation and appeal, particularly among eco-conscious consumers and clients. The shift towards sustainability can ultimately drive sales, as companies prioritize green initiatives to attract clientele. Additionally, potential savings by eliminating dependence on fluctuating energy prices contribute to stabilizing operational costs over the long term.

Investors are increasingly favoring businesses that emphasize sustainability, creating opportunities for financial backing from socially responsible investment funds. Thus, beyond the direct savings on energy costs, solar power integration can enhance market competitiveness and drive long-term profitability.

FREQUENTLY ASKED QUESTIONS

WHAT ARE THE PRIMARY BENEFITS OF SOLAR POWER FOR FACTORIES?

Solar power offers numerous advantages for factories, including substantial cost savings on energy expenditures, a reduced carbon footprint, and enhanced corporate social responsibility. By harnessing renewable energy, manufacturing units can decrease their reliance on fossil fuels, thereby contributing positively to environmental sustainability. Furthermore, solar energy is often accompanied by attractive financial incentives and tax credits that can significantly offset initial installation costs. Long-term, solar power systems can enhance energy independence, providing stable and predictable electricity costs which shield factories from fluctuating energy prices.

HOW CAN A FACTORY DETERMINE THE NUMBER OF SOLAR PANELS REQUIRED?

Calculating the number of solar panels needed for a factory involves assessing the energy consumption profile of the facility, along with several external factors. Firstly, it is crucial to evaluate the total energy demand measured in kilowatt-hours (kWh). Subsequently, one must consider the sunlight availability in the geographical location, factoring in average peak sun hours. By understanding these elements, factories can utilize solar calculators or consult with energy experts to estimate the number of panels required to meet operational energy demands efficiently.

WHAT MAINTENANCE IS NECESSARY FOR SOLAR POWER SYSTEMS IN FACTORIES?

Maintenance requirements for factory solar power systems primarily include regular cleaning of solar panels to remove dust and debris, which can obstruct sunlight absorption and reduce efficiency. In addition, periodic inspections of the entire solar power infrastructure, including inverters and cables, are crucial to identify any wear and tear. Utilizing smart monitoring technologies can also aid in real-time tracking of system performance and quickly detect issues. By adopting a proactive maintenance strategy, factories can ensure optimal efficiency and prolong the life of their solar power investments.

The significance of factory solar power generation in today’s industrial landscape cannot be understated. The processes involved in converting sunlight into usable energy encapsulate a spectrum of benefits that contribute not only to decreasing operational costs but also to fostering sustainability. With an array of solar panels transforming sunlight into electricity, inverters ensuring that power is in a usable format, and batteries providing essential storage, the setup for renewable energy in factories is robust and effective. Furthermore, optimizing the efficiency of such systems through proper maintenance, strategic positioning of panels, and utilizing cutting-edge technologies enhances their efficacy.

Financial implications also play a crucial role in influencing the adoption of solar technologies in factories. While the initial investment might appear daunting, the long-term savings on electricity coupled with available incentives make the transition economically viable. As the manufacturing sector moves towards more sustainable practices, embracing solar power becomes an imperative that reflects broader environmental goals while simultaneously appealing to an increasingly conscious market. The insights into how factory solar power generation works elucidate an integrated system that meets energy needs while paving the path toward a greener future. Ultimately, this transformative process marks a progressive step for industries ready to thrive in a sustainable and economically prudent manner.

Original article by NenPower, If reposted, please credit the source: https://nenpower.com/blog/how-does-factory-solar-power-generation-work/